A pressure sensor measures the pressure of a gas or liquid and converts it into an electrical signal. Types include piezo resistive, capacitive, and optical pressure sensors.

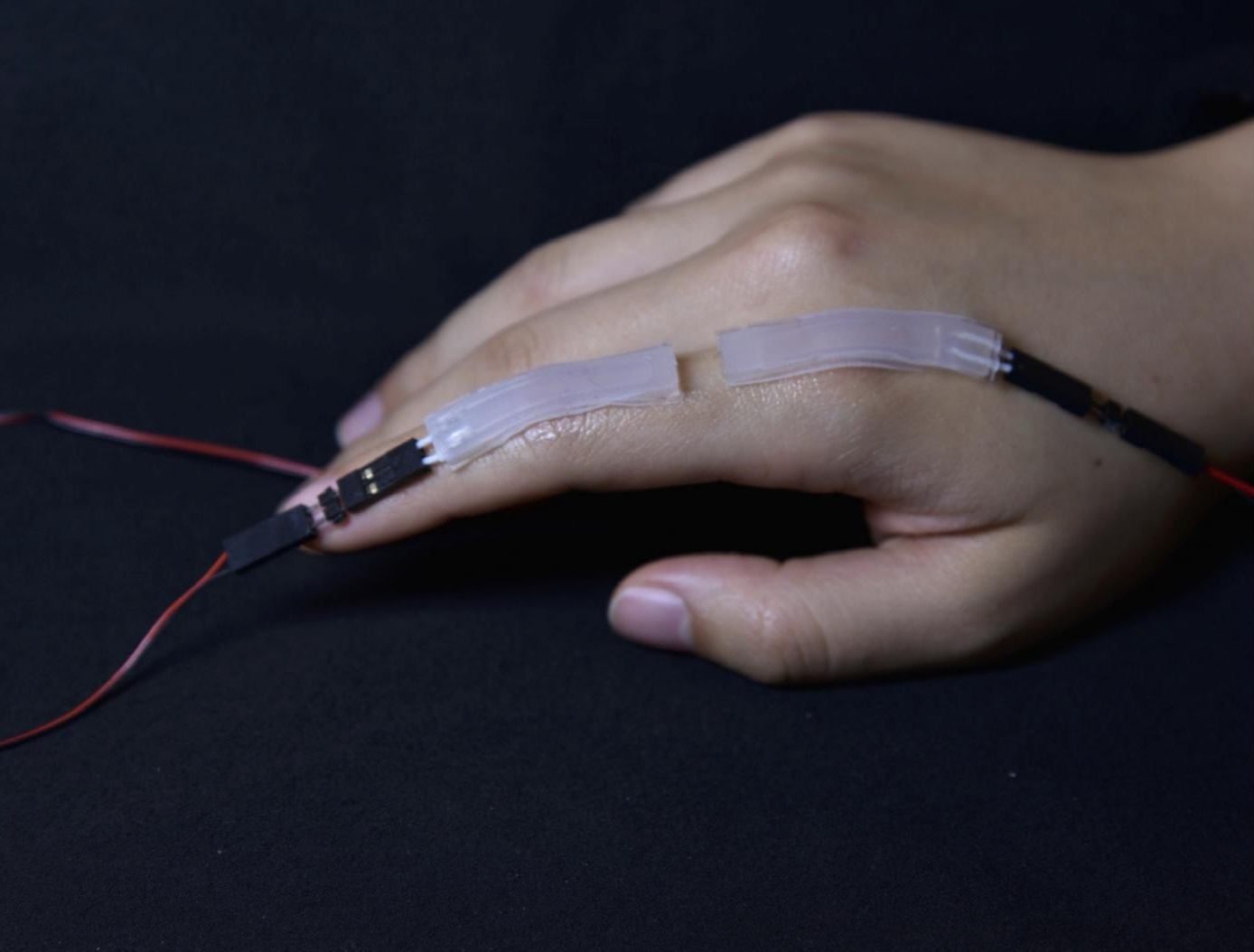

A pressure sensor is a device that measures the force or pressure being applied to it by a fluid, gas, or liquid. It detects and converts this pressure into an electrical signal that can be interpreted and used for various applications. Pressure sensors are commonly used in industrial, automotive, medical, and consumer electronics sectors to monitor and control pressure levels in systems and processes.

Pressure sensors work based on different principles, but most commonly, they use a sensing element that deforms when exposed to pressure. This deformation is typically converted into an electrical signal proportional to the applied pressure.

Pressure sensors types based on their technology

Pressure sensors can come in various forms, such as piezo resistive, capacitive, piezoelectric, or optical sensors. Each type operates based on different principles but shares the common goal of accurately sensing and measuring pressure. Some common types of pressure sensors include:

Piezoresistive Pressure Sensors

Piezoresistive pressure sensors are devices that use the piezo resistive effect to measure the pressure of fluids or gases. The piezo resistive effect refers to the change in electrical resistance of certain materials when they are subjected to mechanical stress or strain.

In a piezoresistive pressure sensor, a thin layer or diaphragm made of a piezoresistive material, such as silicon, is subjected to the pressure being measured. As the pressure changes, the diaphragm flexes, causing a change in the resistance of the piezoresistive material. This change in resistance can be measured and converted into a pressure reading.

Top view of the piezoresistive pressure sensor. Four piezoresistors are placed on each edge forming a Wheatstone bridge circuit.

Cross section A–A showing deflected diaphragm with piezoresistors at maximum stress locations

Piezoresistive pressure sensors offer several advantages, including their high sensitivity, accuracy, and reliability. They can measure a wide range of pressures and are commonly used in applications where precise pressure measurements are required, such as industrial process control, automotive systems, and biomedical devices.

These sensors are known for their robustness and ability to withstand harsh environmental conditions. However, they may require temperature compensation to ensure accurate readings since their performance can be influenced by temperature variations.

Capacitive Pressure Sensors

Capacitive pressure sensors are devices that use changes in capacitance to measure the pressure of a fluid or gas. Capacitance is the ability of a system of conductors and insulators to store electrical charge when a voltage is applied across them.

In a capacitive pressure sensor, two conductive plates are separated by an insulating material. When pressure is applied, the spacing between the plates changes, which alters the capacitance of the sensor. This change in capacitance can be measured and converted into a pressure reading.

The advantages of capacitive pressure sensors include their high accuracy, stability, and low power consumption. They also have good linearity over a wide pressure range and can be easily integrated into electronic systems for precise pressure measurements.

Capacitive pressure sensors find applications in various industries such as automotive, aerospace, consumer electronics, and HVAC systems. They are commonly used in pressure monitoring and control systems, airbag deployment systems, and medical devices.

It’s important to note that the performance of capacitive pressure sensors can be affected by factors such as temperature, humidity, and electromagnetic interference. Proper calibration and environmental considerations are necessary for accurate measurements.

Piezoelectric Pressure Sensors

Piezoelectric pressure sensors are devices that use the piezoelectric effect to measure the pressure of a fluid or gas. The piezoelectric effect is the ability of certain materials to generate an electric charge in response to applied mechanical stress.

In a piezoelectric pressure sensor, a thin piezoelectric crystal or ceramic material is bonded to a diaphragm. When pressure is applied to the diaphragm, it flexes and causes mechanical stress on the piezoelectric material. This stress generates an electrical charge, which can be measured and converted into a pressure reading.

The advantages of piezoelectric pressure sensors include their high sensitivity, wide frequency response, and ability to withstand harsh environments. They are commonly used in various industries such as automotive, aerospace, medical, and industrial applications.

Piezoelectric pressure sensors can be found in applications like engine combustion analysis, tire pressure monitoring systems, industrial process control, and biomedical devices, among others. Their accuracy and reliability make them popular for measuring dynamic pressure changes in real-time.

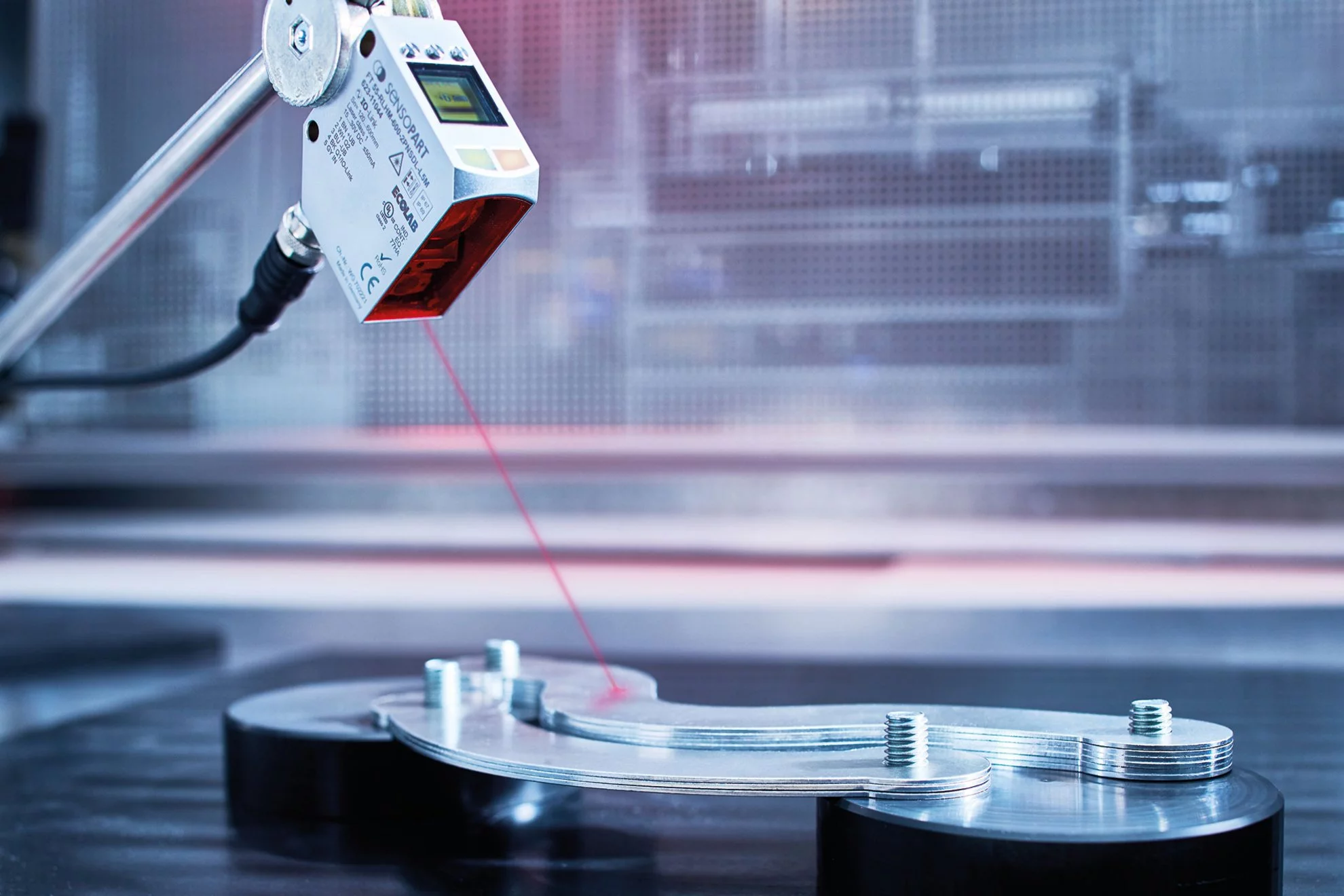

Optical Pressure Sensors

Optical pressure sensors are devices that use light-based technology to measure pressure. These sensors utilize various optical principles, such as reflection, refraction, absorption, or interference, to detect pressure-induced changes and convert them into measurable signals.

One common type of optical pressure sensor is the fiber optic pressure sensor. It consists of a diaphragm that flexes in response to pressure, causing changes in the intensity, phase, or wavelength of light traveling through it. These changes can be detected and analyzed to determine the pressure being applied.

Fiber optic pressure sensors offer several advantages. They are immune to electromagnetic interference, have high sensitivity, and can be designed to measure pressure in extreme environments, including high temperatures, corrosive fluids, or explosive atmospheres. Additionally, they are often small, lightweight, and flexible, making them suitable for various applications.

Another type of optical pressure sensor is the Fabry-Perot interferometer sensor. It uses the interference of light waves to measure pressure. The pressure-induced changes in the gap between two parallel surfaces result in variations in the interference pattern, which can be analyzed to determine pressure.

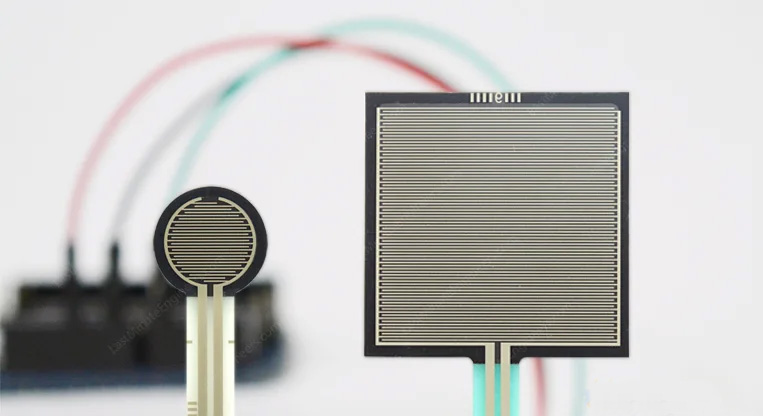

Strain Gauge Pressure Sensors

Strain gauge pressure sensors are devices that utilize the principle of strain to measure pressure. They consist of a flexible diaphragm that deforms when pressure is applied and a strain gauge bonded to the diaphragm. The strain gauge is a thin wire or foil made of a conductive material.

When pressure is exerted on the diaphragm, it undergoes deformation, causing the strain gauge to stretch or compress. This change in length or shape leads to a change in the electrical resistance of the strain gauge. By measuring this change in resistance, the pressure applied to the diaphragm can be determined.

Strain gauge pressure sensors have various advantages. They offer good accuracy, high sensitivity, and a wide measurement range. They are also relatively simple in design, cost-effective, and can be easily integrated into different systems and applications.

However, it’s essential to note that strain gauge pressure sensors often require amplification and signal conditioning to obtain accurate and reliable measurements. This is because the change in resistance is typically small and needs to be converted into a usable electrical signal.

These sensors find applications in many industries, including automotive, aerospace, industrial automation, and healthcare. They are commonly used for pressure measurement in devices like pressure transducers, manometers, and pressure monitoring systems.

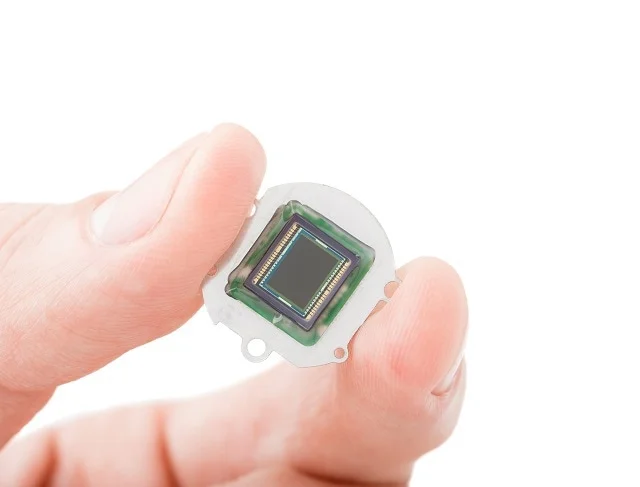

MEMS (Microelectromechanical Systems) Pressure Sensors

These sensors use miniaturized and integrated microstructures to measure pressure. They often combine various sensing elements and electronics on a single chip, making them small in size and suitable for portable devices.

These are just a few examples of pressure sensor types, but there are many more variations and specialized sensors available depending on the specific application requirements.

Pressure sensor types based on their measurement principles

Pressure sensors can be categorized based on the measurement principles they employ. Some common types include:

Absolute Pressure Sensors

Absolute pressure sensors are designed to measure pressure relative to a perfect vacuum, which is considered as absolute zero pressure. These sensors typically employ a sealed reference chamber that is completely evacuated of air molecules.

An absolute pressure sensor measures the total pressure acting on it, including both atmospheric pressure and any additional pressure from the measured source. By subtracting the atmospheric pressure from the total pressure reading, the specific pressure of the source can be determined. These sensors are commonly used in applications where the pressure measurement needs to be referenced to a vacuum, rather than to atmospheric pressure.

Absolute pressure sensors can utilize different technologies to measure pressure, such as strain gauges, piezoelectric elements, capacitive elements, or optical methods. Each technology has its own advantages and

limitations, and the choice depends on factors such as accuracy requirements, temperature range, and environmental conditions.

Gauge Pressure Sensors

Gauge pressure sensors are designed to measure pressure relative to atmospheric pressure. They provide a measurement of the pressure above or below atmospheric pressure, also known as the gauge pressure. Unlike absolute pressure sensors that measure pressure relative to a perfect vacuum, gauge pressure sensors do not have a sealed reference chamber and rely on the surrounding atmospheric pressure as their reference point.

Gauge pressure sensors are commonly used in a wide range of applications where the measurement of pressure relative to the ambient atmospheric pressure is sufficient.

Just like what it was said for absolute pressure sensors, gauge pressure sensors can utilize different technologies such as strain gauges, piezoresistive elements, capacitive elements, or vibrating elements to measure pressure. The choice of technology depends on factors such as accuracy requirements, temperature range, and environmental conditions.

In summary, gauge pressure sensors are widely used to measure pressure relative to atmospheric pressure and provide valuable information for numerous industrial, automotive, and environmental applications.

Differential Pressure Sensors

Differential pressure sensors are designed to measure the difference in pressure between two points. They provide a measurement of the pressure drop or pressure differential across a device, system, or component. These sensors are commonly used in applications where it is important to monitor and control pressure variations, flow rates, or fluid levels.

Differential pressure sensors work by comparing the pressures at two different locations. The sensor has two ports – one for each pressure source. The pressure difference between these two ports is measured and converted into an electrical signal that can be displayed or utilized by a control system. They

find applications in HVAC systems, cleanrooms, medical equipment, industrial processes, and energy management, among others, contributing to better control, safety, and efficiency in various industries.

Vacuum Pressure Sensors

These sensors specifically measure pressures below atmospheric pressure, typically in the range of a few millibars (mbar) to micropascals (µPa).

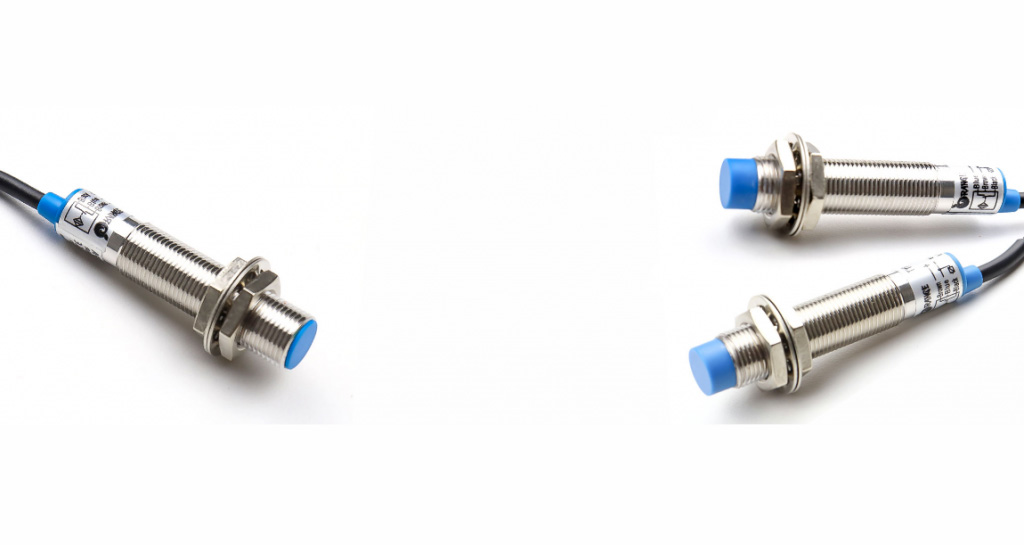

Sealed Pressure Sensors

These sensors are designed for harsh environments where the sensing element needs to be protected from contact with the measured fluid. They have a sealed enclosure to prevent any direct contact.

These are some of the pressure sensor types based on the measurement principles they utilize. Each type has its advantages and applications, so choosing the appropriate type depends on the specific requirements of the application.

The lifespan of a pressure sensor depends on various factors, including the quality of the sensor, operating conditions, and maintenance. Generally, well-maintained pressure sensors can last for several years.

To choose the right pressure sensor, consider factors such as the pressure range, accuracy requirements, environmental conditions (temperature, humidity, etc.), compatibility with the fluid or gas being measured, and any specific features needed for your application.

Some considerations when using pressure sensors include their sensitivity to temperature changes, compatibility with the medium being measured (corrosive substances, high viscosity fluids, etc.), and the need for proper installation and protection against external influences like vibrations or excessive pressure spikes.

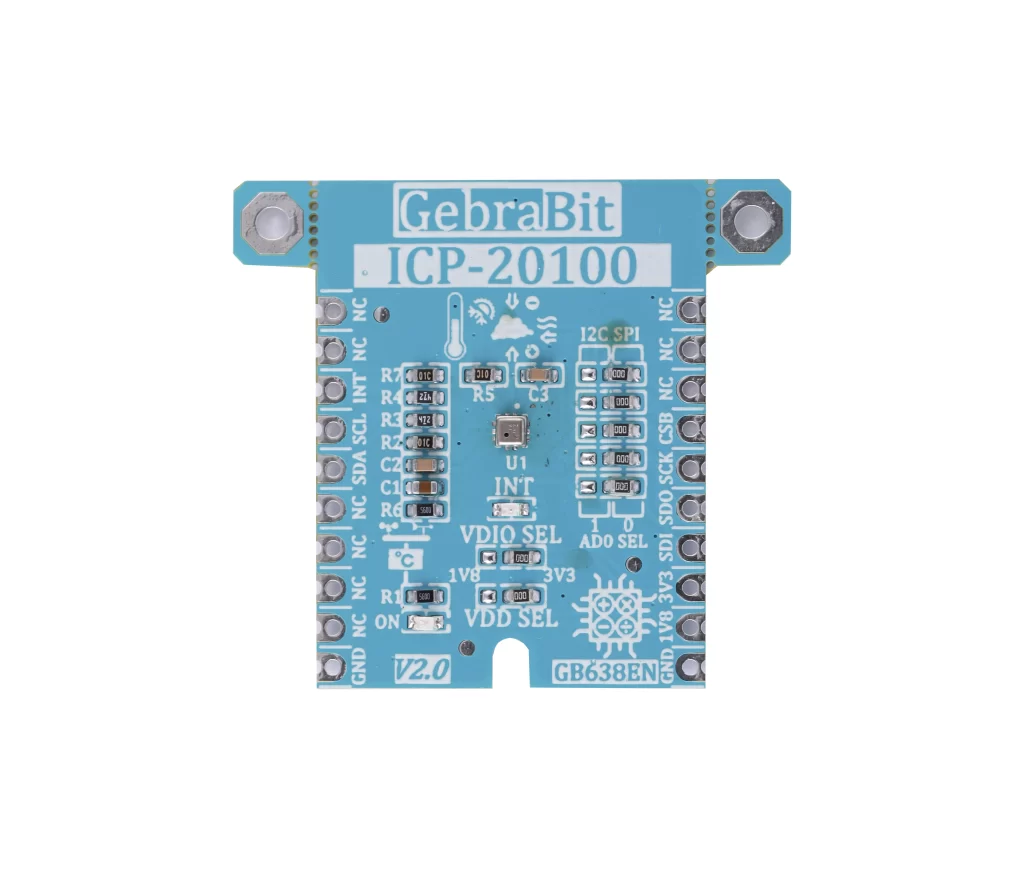

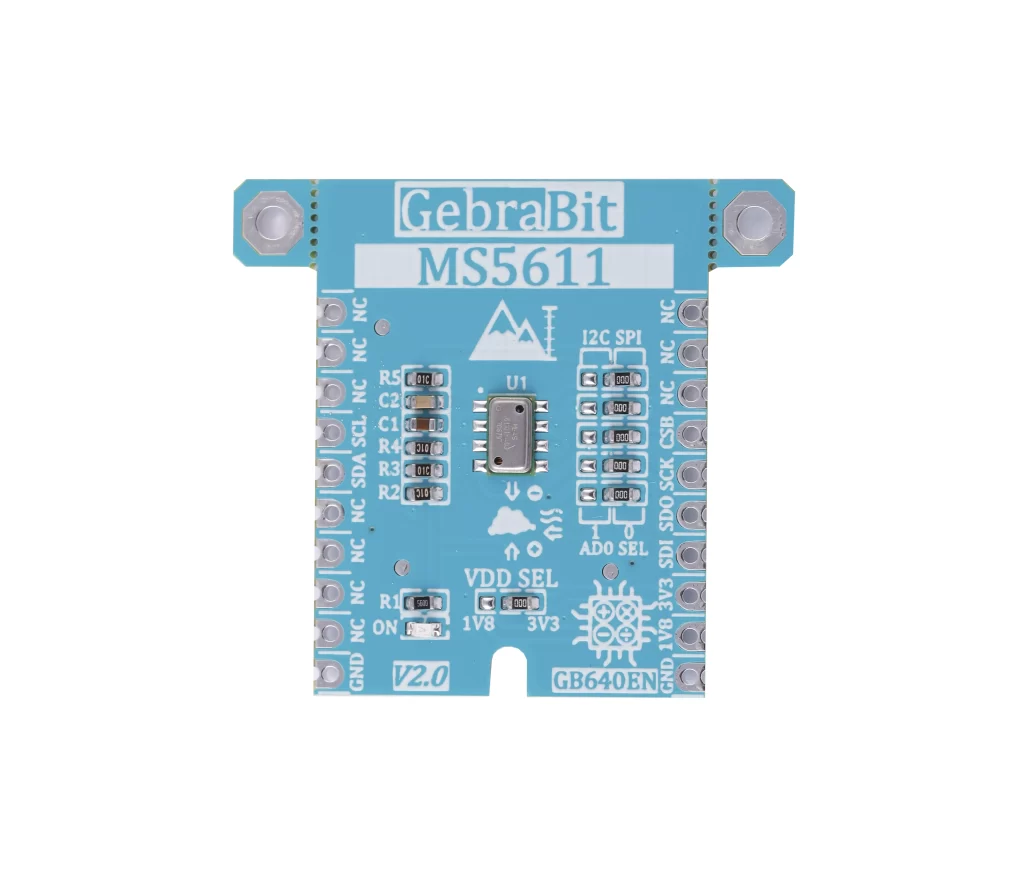

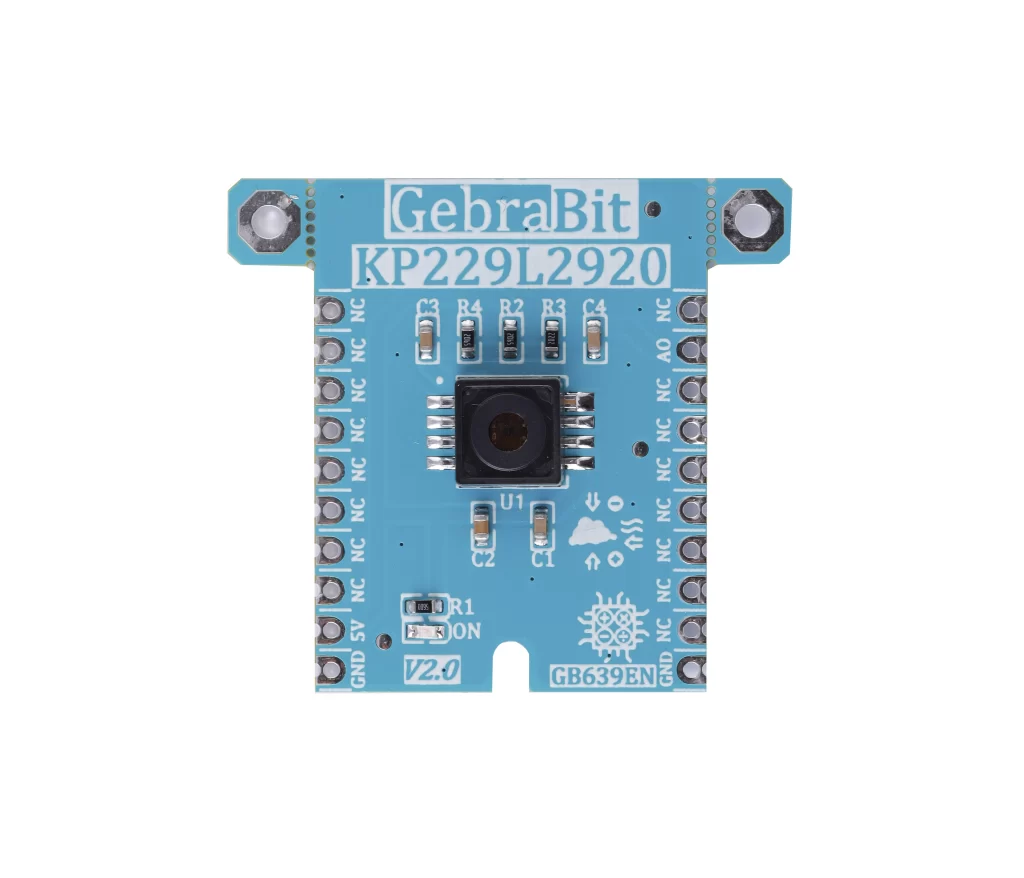

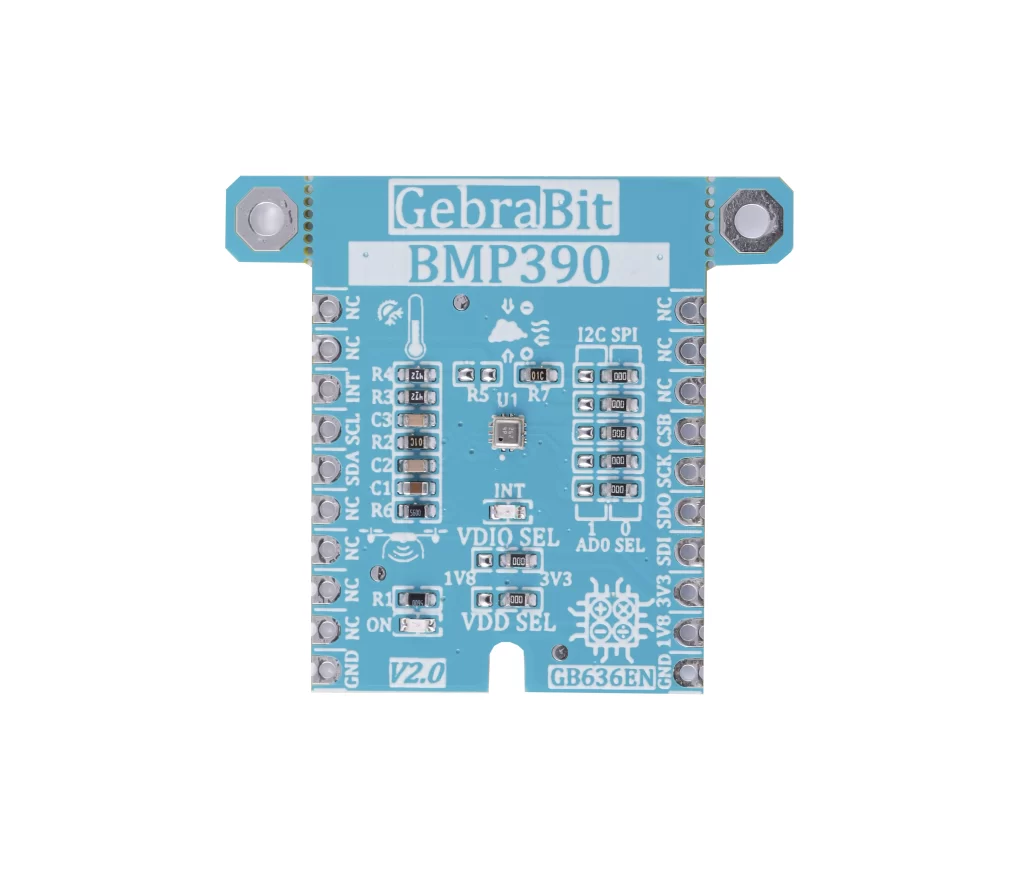

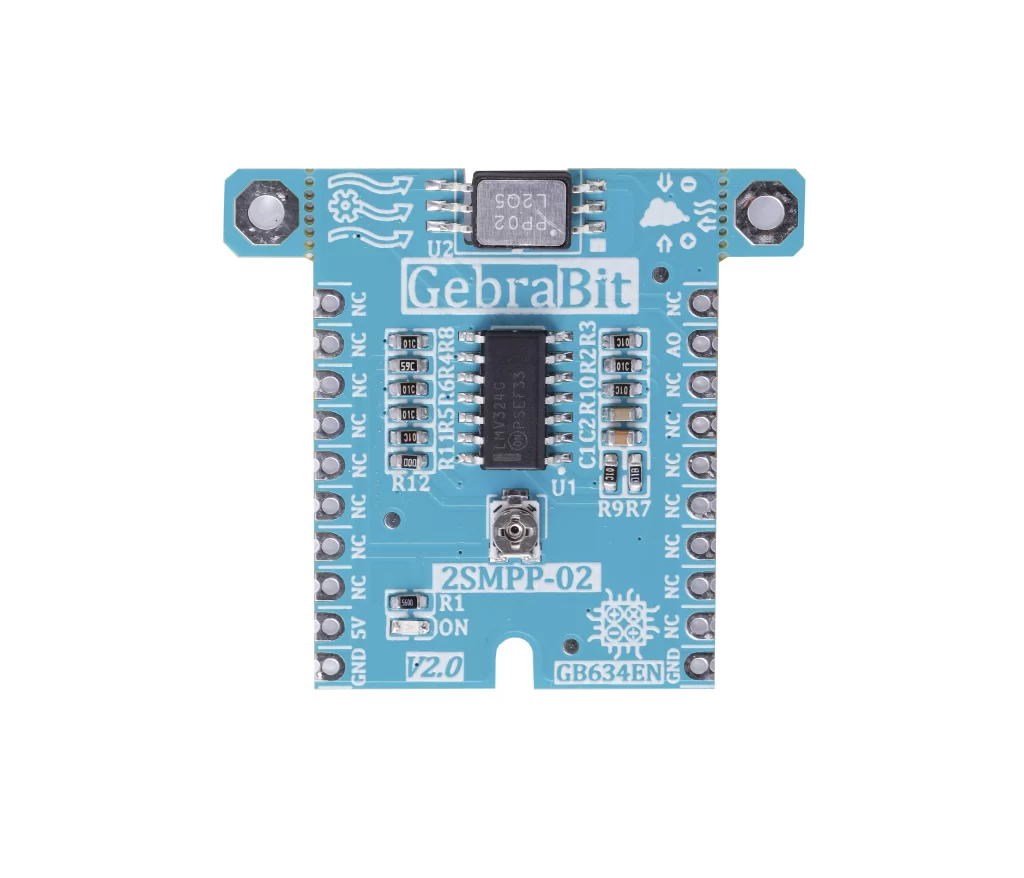

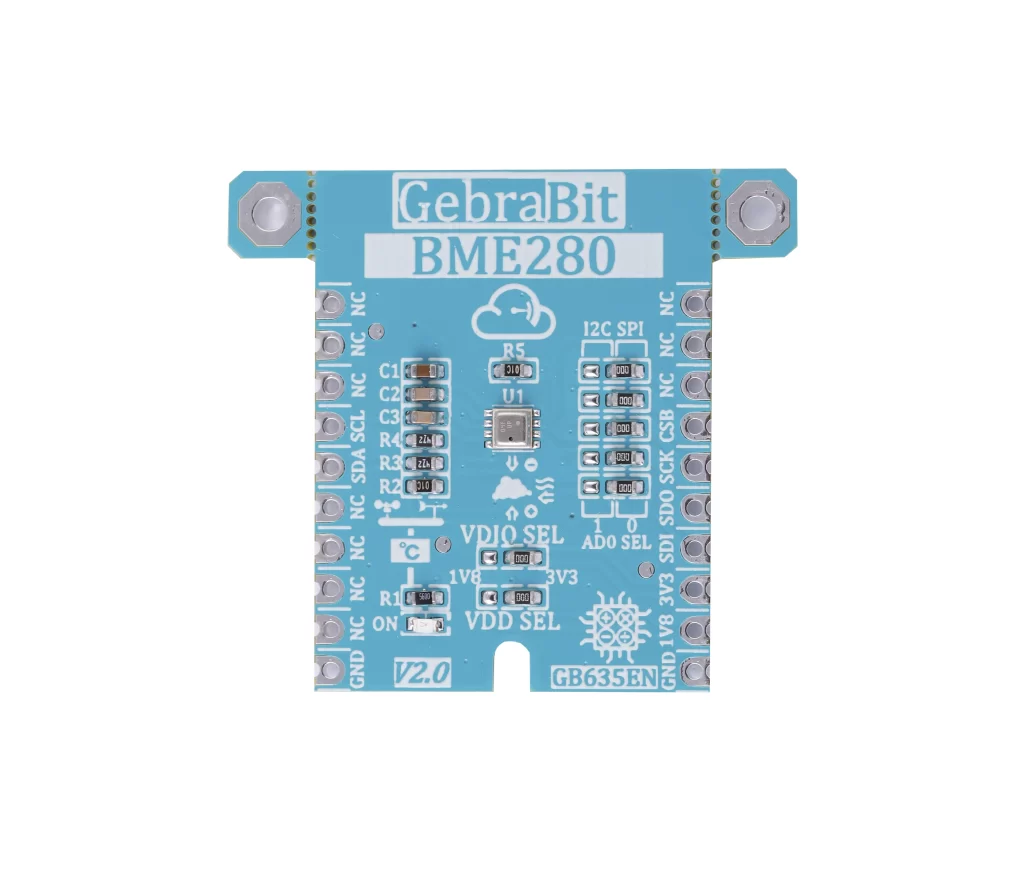

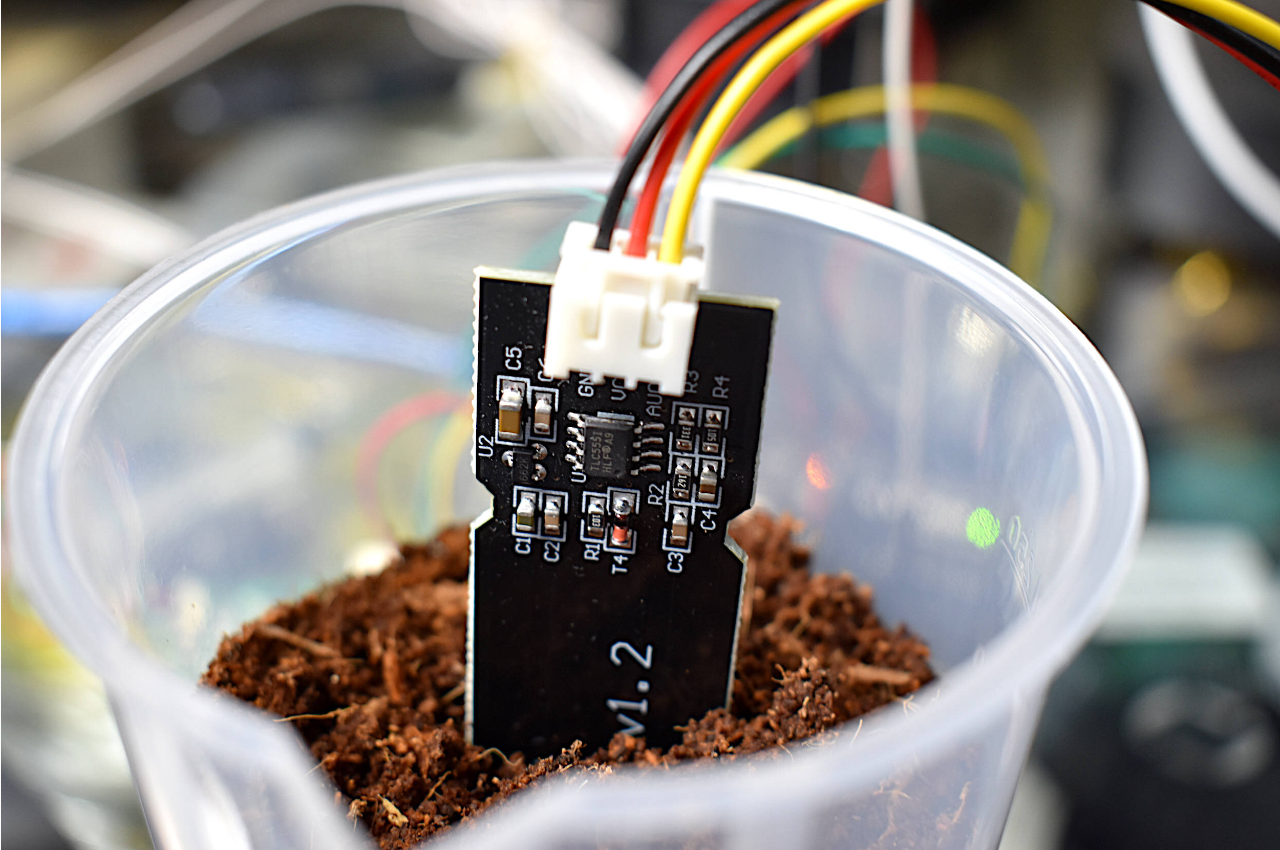

GebraBit Pressure Sensors

Here are the pressure sensors made by GebraBit team to ease your work. You can read about each of them by clicking on its title