A flow sensor measures the flow rate or volume of a fluid. It is commonly used in various industries such as HVAC, water management, and process control. Types include turbine flow sensors, electromagnetic flow sensors, and thermal flow sensors. Applications include flow measurement in pipelines, fuel consumption monitoring, water flow control, and chemical process monitoring.

A flow sensor is a device used to measure the rate of fluid flow in a system. It is commonly used in various industries for monitoring and controlling the flow of liquids or gases.

Different types of flow sensors and how they work

Flow sensors work on different operating principles depending on their type. Some common types include the thermal, mechanical, ultrasonic, and magnetic flow sensors. Each type operates based on specific physical properties.

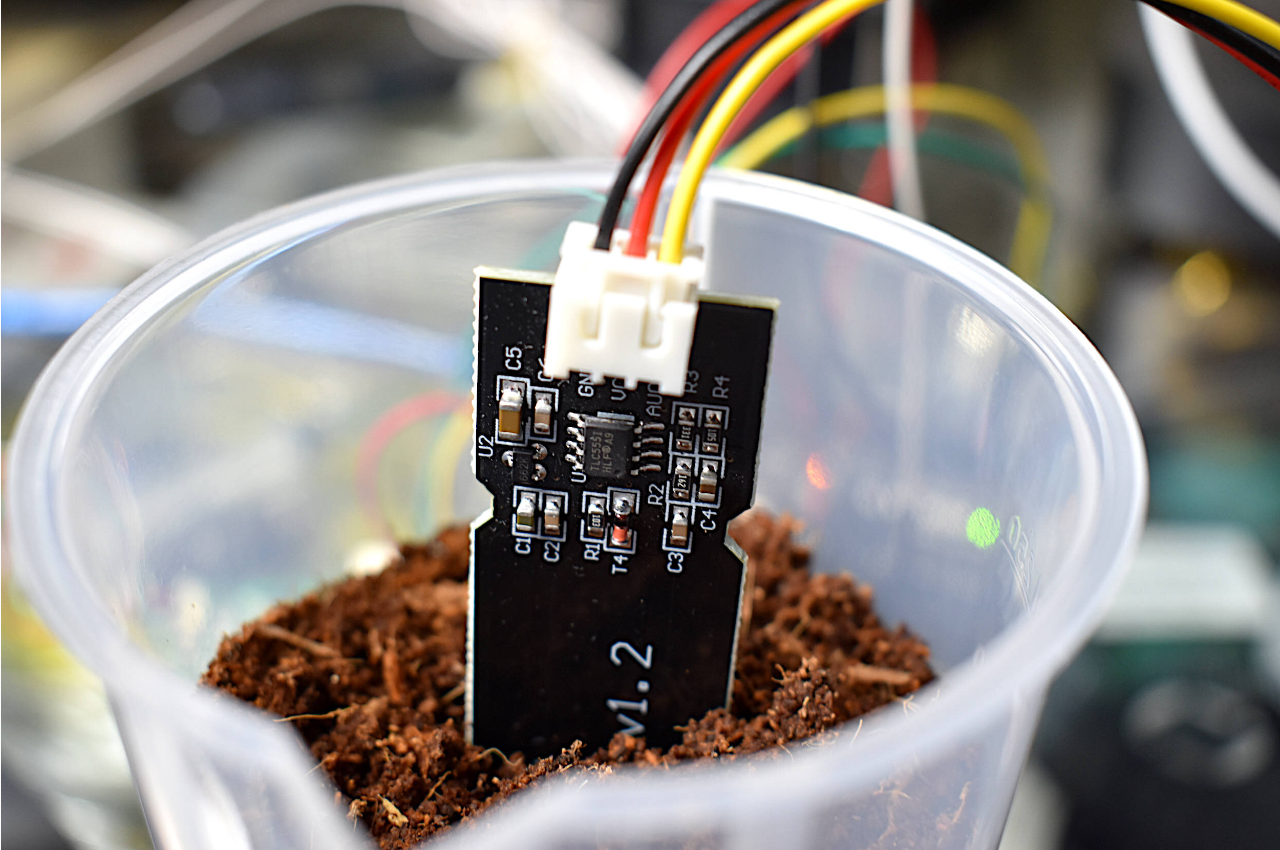

Thermal Flow Sensors

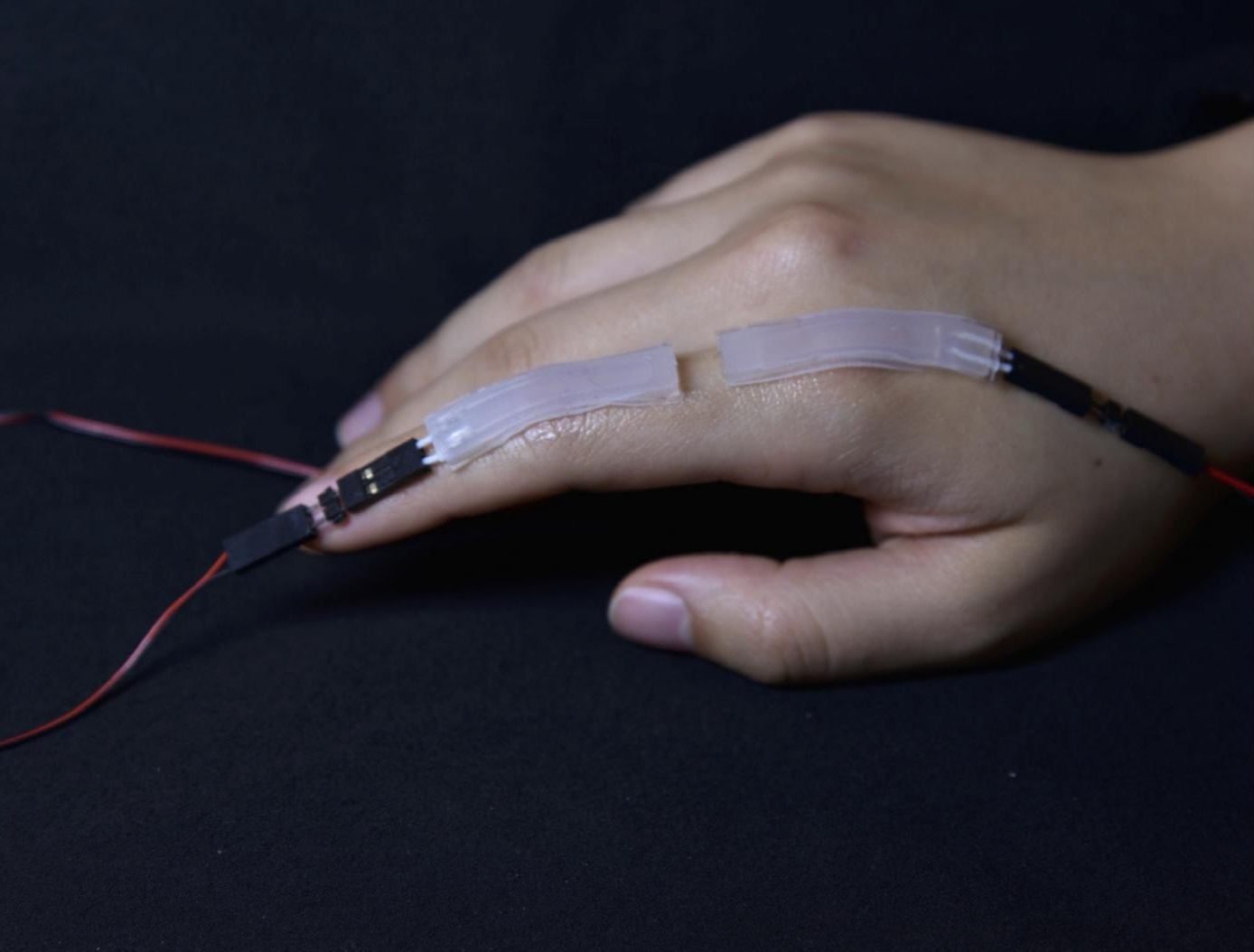

Thermal flow sensors are devices that measure fluid flow based on the principle of heat transfer. They are commonly used to measure the flow rate of gases in various applications.

Thermal flow sensors consist of a heated element, often a thin-film or wire-wound resistor, which is placed in the fluid flow path. The element is electrically heated to a specific temperature.

There are one or more temperature sensors, such as thermocouples or resistance temperature detectors (RTDs), located upstream and downstream of the heated element. These sensors measure the fluid temperature before and after passing through the heated element.

As the fluid flows over the heated element, it absorbs heat due to the temperature difference between the element and the fluid. The amount of heat transferred is directly proportional to the fluid flow rate.

The temperature sensors measure the change in temperature caused by the heat transfer process. By comparing the temperatures before and after the heated element, the thermal flow sensor calculates the rate at which heat energy has been transferred to the fluid.

Using the known properties of the fluid, such as its specific heat capacity, density, and thermal conductivity, the thermal flow sensor converts the measured temperature difference into a flow rate value. The conversion is typically done using built-in algorithms or calibration curves specific to the sensor.

The output of a thermal flow sensor can be an analog signal such as voltage or current, or a digital signal. This output is proportional to the fluid flow rate and can be further processed by a control system or displayed on a user interface.

Thermal Flow Sensors applications:

Thermal flow sensors are widely used in applications such as HVAC systems, gas flow monitoring, chemical processing, and industrial process control. Proper calibration and regular maintenance are crucial to maintaining accuracy and reliability in thermal flow sensor readings.

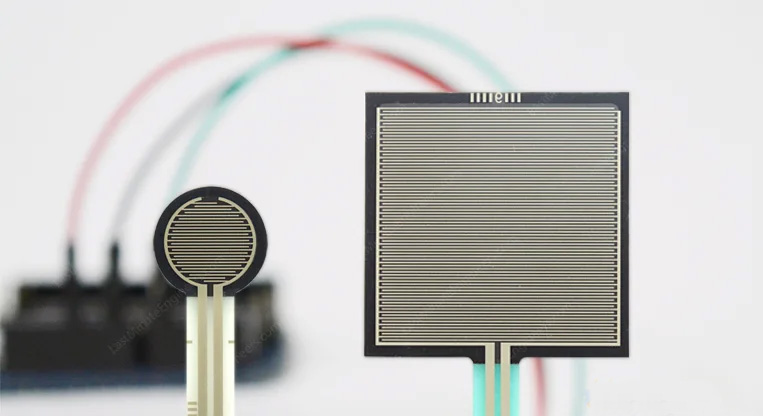

Mechanical Flow Sensors

Mechanical flow sensors, also known as volumetric flow sensors, are devices that measure fluid flow based on mechanical principles. They are commonly used to measure the flow rate of liquids in various applications.

One common type of mechanical flow sensor is the obstruction-based sensor. These sensors use an obstruction in the flow path, such as a paddle wheel or turbine, which rotates when fluid flows through it.

As the fluid flows through the sensor, the obstruction (paddle wheel or turbine) starts rotating. The rotation speed is directly proportional to the flow rate of the fluid. The sensor incorporates a mechanism to measure and translate this rotation into a flow rate value.

Mechanical flow sensors often include a gear or spinner mechanism that converts the rotational motion into a measurable quantity. This could be a mechanical gear train or a magnetic coupling system.

The rotation of the obstruction is typically coupled with a gear or spinner mechanism connected to a mechanical or electronic counter, encoder, or sensor. This coupling translates the rotation into a measurable unit, such as pulses or electrical signals.

The output of a mechanical flow sensor can be analog or digital. Analog outputs can be in the form of voltage, current, or frequency. Digital outputs can be in the form of pulses or digital signals, which can be further processed by a control system or displayed on a user interface.

Mechanical Flow Sensors characteristics and applications:

Mechanical flow sensors require proper calibration to ensure accuracy. The calibration process involves determining the relationship between the flow rate and the sensor output. Regular maintenance and periodic recalibration are essential to maintain accurate readings.

The compatibility of the mechanical flow sensor with the characteristics of the fluid being measured, such as viscosity, temperature, and pressure. Mechanical flow sensors are commonly used in applications such as water treatment, irrigation systems, fuel monitoring, and industrial process control.

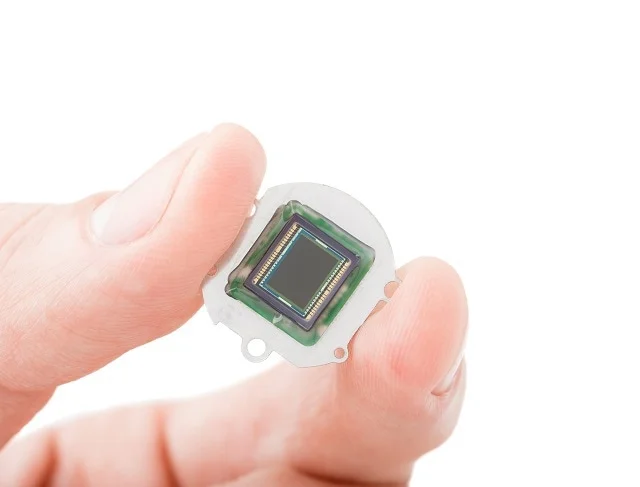

Ultrasonic Flow Sensors

Ultrasonic flow sensors are devices that measure fluid flow using ultrasonic waves. They are commonly used in various applications where non-invasive flow measurement is required.

Ultrasonic flow sensors utilize the propagation of ultrasonic waves through a fluid to measure its flow rate. The sensors have transducers that emit ultrasonic signals and receive the echoes or reflections from the fluid.

One common method used by ultrasonic flow sensors is the transit time method. In this method, two transducers are placed at opposite sides of the pipe or channel through which the fluid flows. One transducer acts as a sender, emitting ultrasonic waves, while the other acts as a receiver, capturing the reflected waves.

The ultrasonic waves emitted by the sender transducer travel through the fluid in both upstream and downstream directions. The time it takes for the waves to travel between the two transducers is measured separately for the upstream and downstream paths.

By comparing the travel times of the ultrasonic waves in each direction, the relative velocity of the fluid can be determined. The difference in travel times is proportional to the flow rate of the fluid.

Ultrasonic Flow Sensors characteristics and applications:

Factors such as temperature, pressure, and density of the fluid may affect the speed of sound, and thus, need to be taken into account during calculations for accurate flow measurement. Calibration and configuration adjustments may also be required to optimize the performance of ultrasonic flow sensors.

Ultrasonic flow sensors usually provide digital outputs, such as pulse/frequency or serial data. They may also have analog outputs like voltage or current, which can be used for control or monitoring purposes.

Ultrasonic flow sensors offer advantages such as non-invasive measurement, high accuracy, wide rangeability, and the ability to measure different types of fluids. They are commonly used in industries like water and wastewater management, HVAC systems, oil and gas, chemical processing, and many more.

Magnetic Flow Sensors

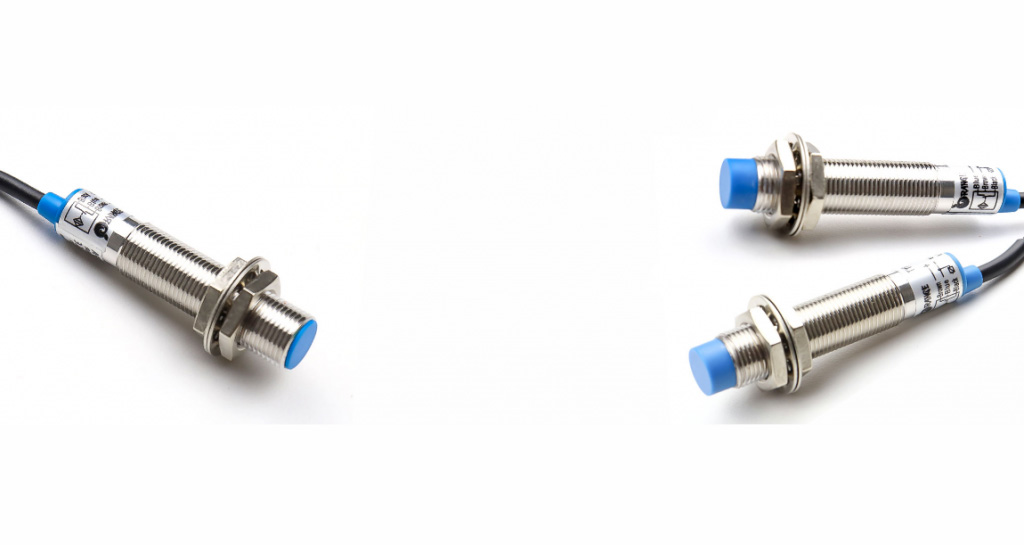

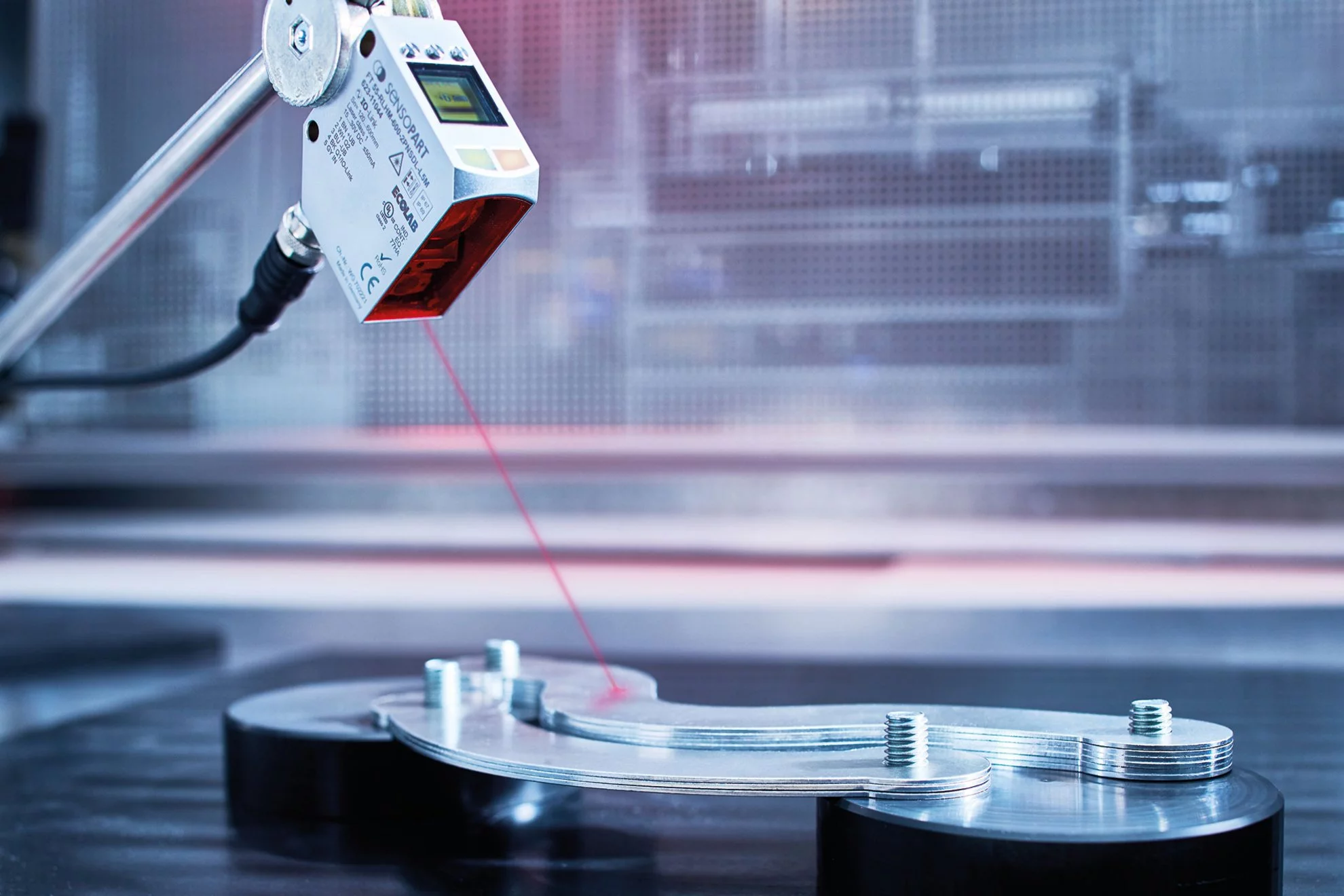

Magnetic flow sensors, also known as electromagnetic flow sensors or magmeters, are devices used to measure the flow rate of conductive fluids. They operate based on the principle of Faraday’s law of electromagnetic induction.

Magnetic flow sensors consist of a pipe or tube with an insulating liner and two electrodes placed opposite each other. When an electrically conductive fluid flows through the pipe, a magnetic field is generated perpendicular to the direction of the flow.

According to Faraday’s law of electromagnetic induction, when a conductive fluid moves through a magnetic field, it induces a voltage proportional to the flow velocity. The induced voltage can be measured by the electrodes.

The induced voltage is directly proportional to the flow velocity. The magnetic flow sensor measures this voltage and converts it into a corresponding flow rate using calibration factors specific to the application.

Magnetic flow sensors require the fluid to have a certain level of electrical conductivity for accurate measurements. This means they are typically used for measuring the flow of liquids such as water, wastewater, slurries, and various other conductive fluids.

Proper installation is crucial for accurate measurements with magnetic flow sensors. The pipe or tube should be full of the conductive fluid, and the electrodes should be aligned correctly to maximize the magnetic field interaction.

Magnetic Flow Sensors characteristics and applications:

Magnetic flow sensors offer benefits like high accuracy, minimal pressure drop, and low maintenance requirements. They are commonly used in industries such as water treatment, chemical processing, food and beverage production, pharmaceuticals, and irrigation systems.

Magnetic flow sensors cannot measure the flow of non-conductive fluids such as oils, gases, or most hydrocarbons. They are specifically designed for conductive liquid flow measurement.