These sensors measure the amount of strain or deformation in an object, and are commonly used in structural monitoring, materials testing, and load cells.

What is strain?

Strain is a term used to describe the deformation or change in shape experienced by an object when subjected to external forces, such as tension, compression, or shear. It is a measure of how much an object’s length, shape, or volume changes relative to its original dimensions.

Strain is typically quantified as a ratio or percentage of the change in length or dimension to its original length or dimension. This ratio is called strain and is denoted by the Greek letter epsilon (ε). It is expressed mathematically as:

ε = ΔL / L

Where:

ε is the strain

ΔL is the change in length or dimension

L is the original length or dimension

Strain can be categorized into different types based on the type of force applied. Common types of strain include:

Tension Strain: This occurs when an object is stretched or pulled apart. It results in an increase in length and a positive strain value.

Compressive Strain: This occurs when an object is compressed or squeezed together. It leads to a decrease in length and a negative strain value.

Shear Strain: This occurs when opposite forces are applied parallel to each other, causing the object to deform by twisting or sliding. Shear strain is calculated as the change in angle between two originally perpendicular lines within the object.

Strain is an important concept in engineering and materials science as it helps to determine an object’s response to external forces, including its strength, elasticity, and overall structural integrity. Strain measurements are often used in fields such as mechanical engineering, civil engineering, and material testing to ensure the safety and reliability of structures and materials.

What is strain sensor?

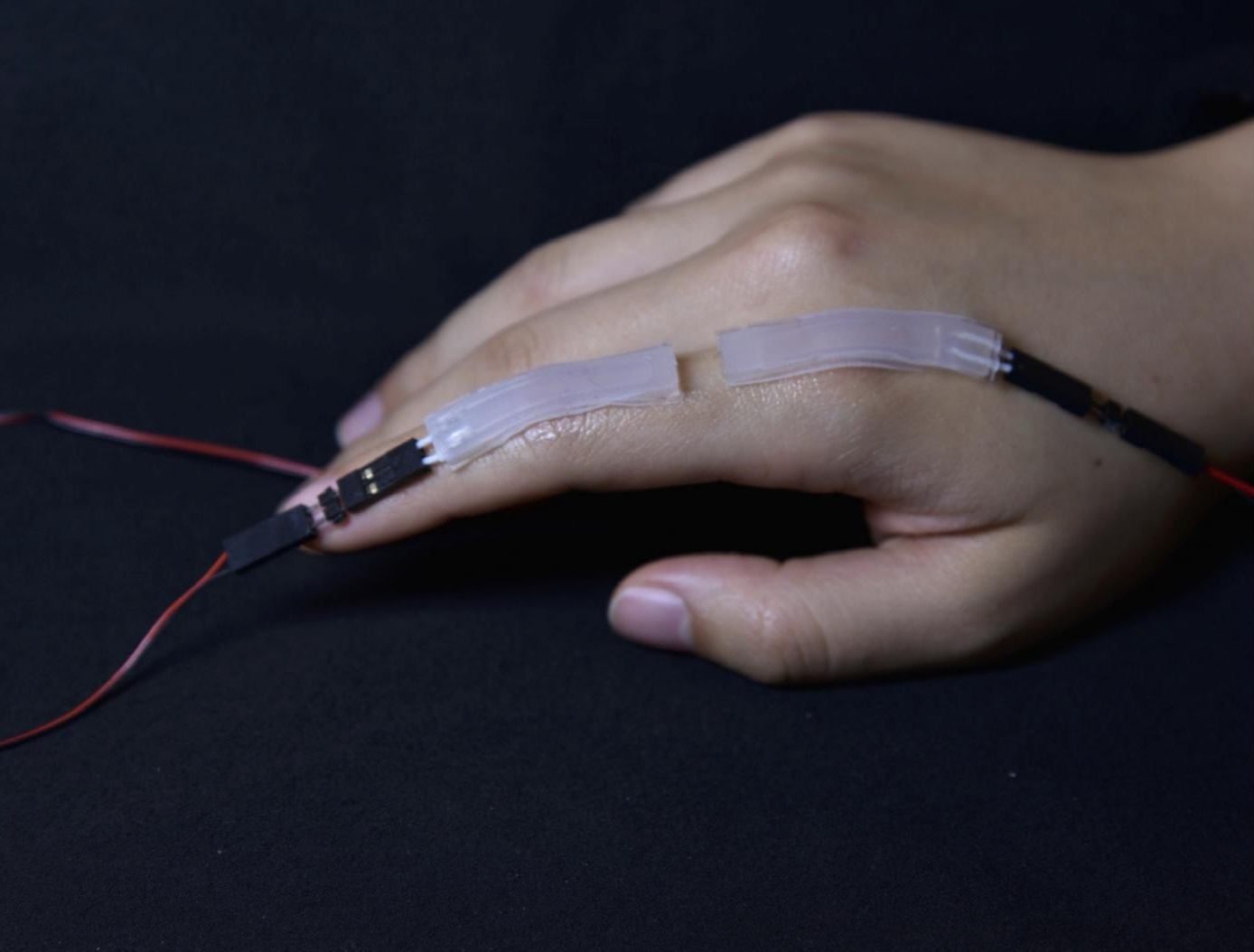

Strain sensors are devices that detect and measure the deformation or changes in shape of an object under applied stress or strain. These sensors are used to monitor and measure various physical quantities such as force, pressure, weight, torque, and structural integrity.

Strain sensors types and how they work

The working principle of strain sensors depends on the type of sensor used. However, the common underlying principle is that strain sensors convert mechanical deformation or strain into an electrical signal that can be measured and analyzed.

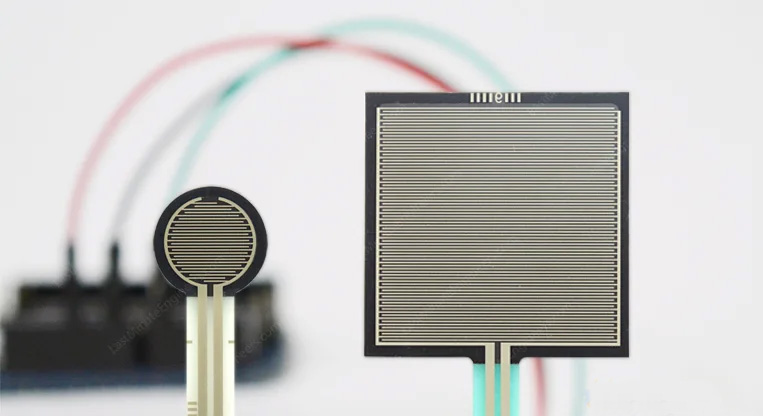

Resistive Strain Gauges

These sensors use a resistive element, such as a metal foil or a semiconductor, that changes its electrical resistance when subjected to strain. The change in resistance is proportional to the applied strain, allowing for measurements to be made.

As it was said, these sensors utilize the change in electrical resistance when a material undergoes strain. A thin conducting element, such as a metal foil or a semiconductor, is bonded to the surface of the object being measured. As the object undergoes deformation, the strain gauge experiences a change in length, causing a proportional change in electrical resistance. This change in resistance can be measured using a Wheatstone bridge circuit, and the applied strain can be calculated based on the resistance change.

Resistive strain gauges are widely used in structural engineering, load testing, and material testing applications.

Capacitive Strain Gauges

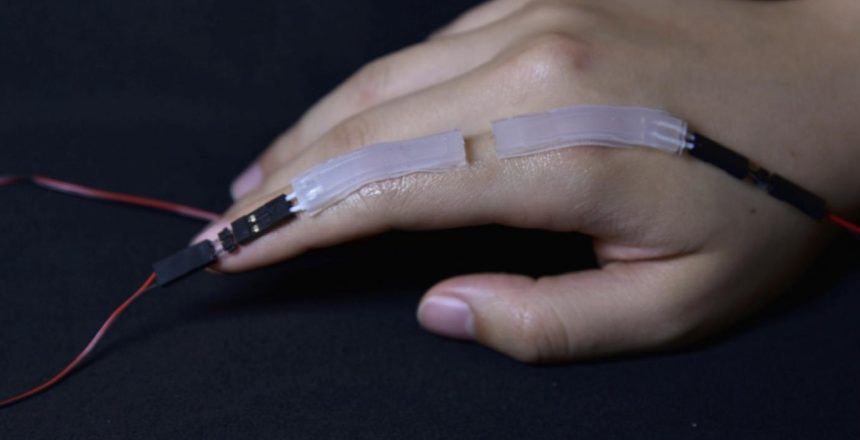

Capacitive strain gauges operate based on the change in capacitance when a material undergoes strain. They consist of two parallel plates separated by a dielectric material. Typically, one plate is fixed while the other is attached to the object being measured.

When strain is applied, the distance between the plates changes, altering the capacitance. This change is measured and correlated to the applied strain. Capacitive strain gauges are often used in high-precision measurements where high sensitivity is required.

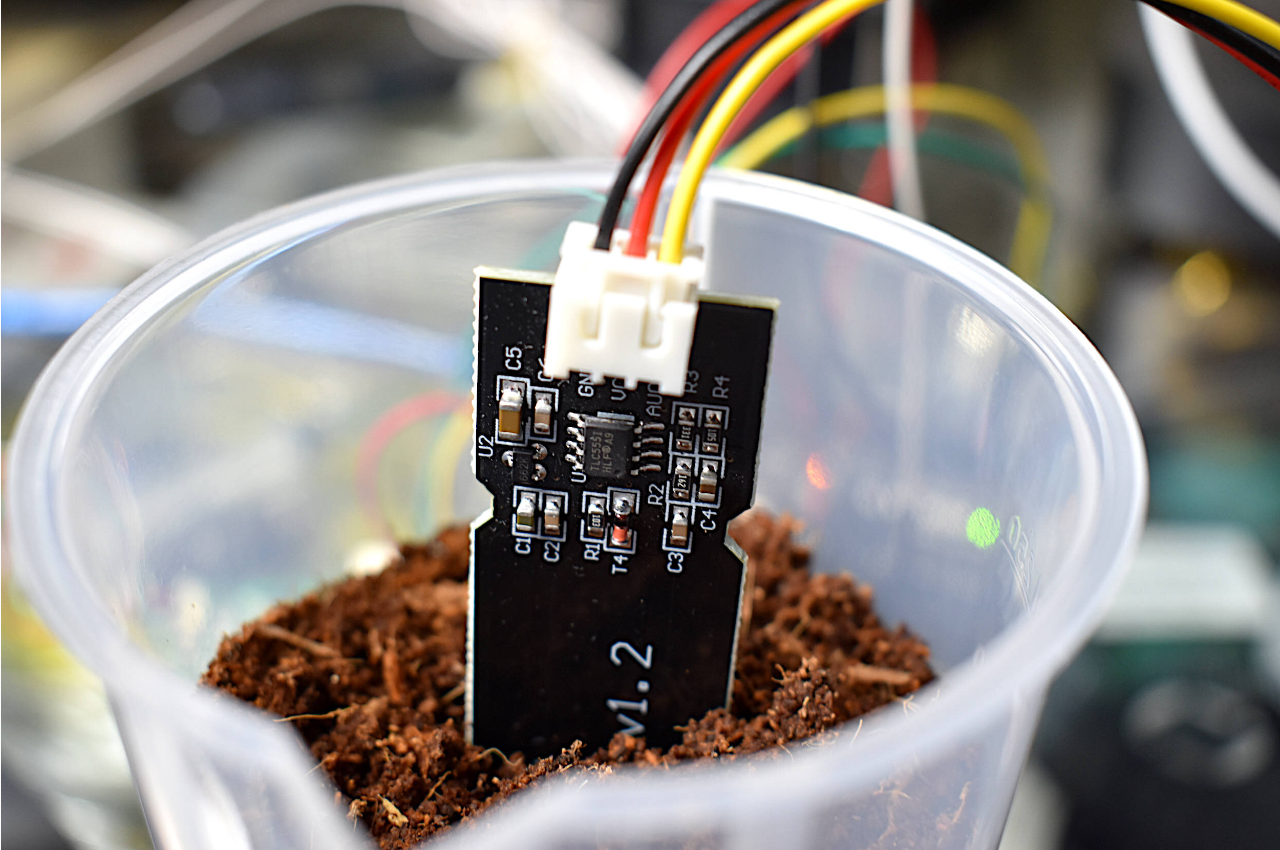

Optical Strain Sensors

These sensors use the principle of light interference or fiber optic technology to measure strain. A specially designed optical fiber is bonded or embedded into the object being measured. As strain is applied, the fiber experiences length changes, leading to changes in light intensity or wavelength. These changes are detected and converted into strain measurements using appropriate optical techniques. Optical strain sensors offer high accuracy, immunity to electromagnetic interference, and can be used in harsh environments.

Piezoelectric Strain Sensors

Piezoelectric materials generate an electric charge when subjected to strain or pressure. In piezoelectric strain sensors, a piezoelectric material is bonded to the surface of the object being measured. When the object undergoes strain, the piezoelectric material generates a proportional electric charge. This charge is measured and converted into strain measurements. Piezoelectric strain sensors find applications in dynamic measurements, impact testing, and vibration analysis.

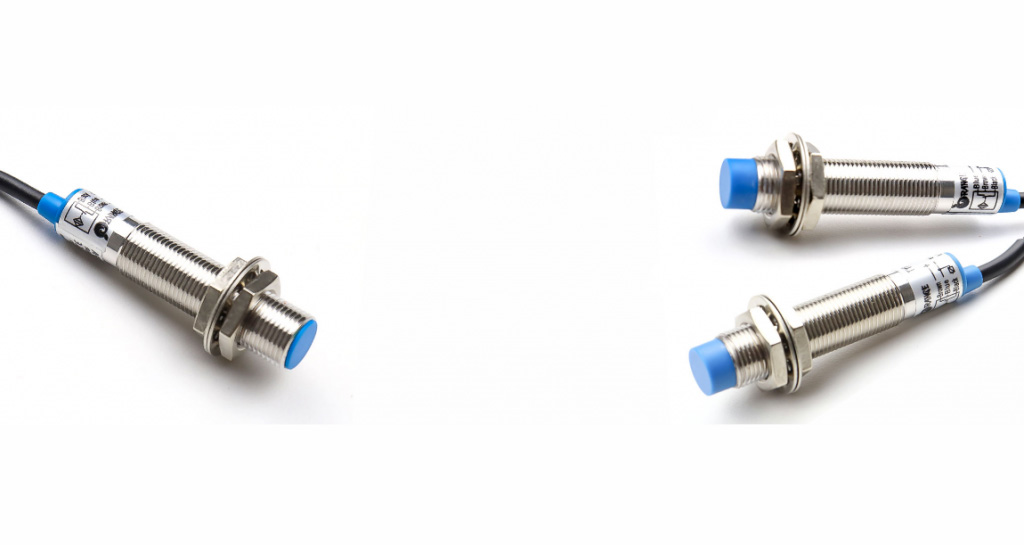

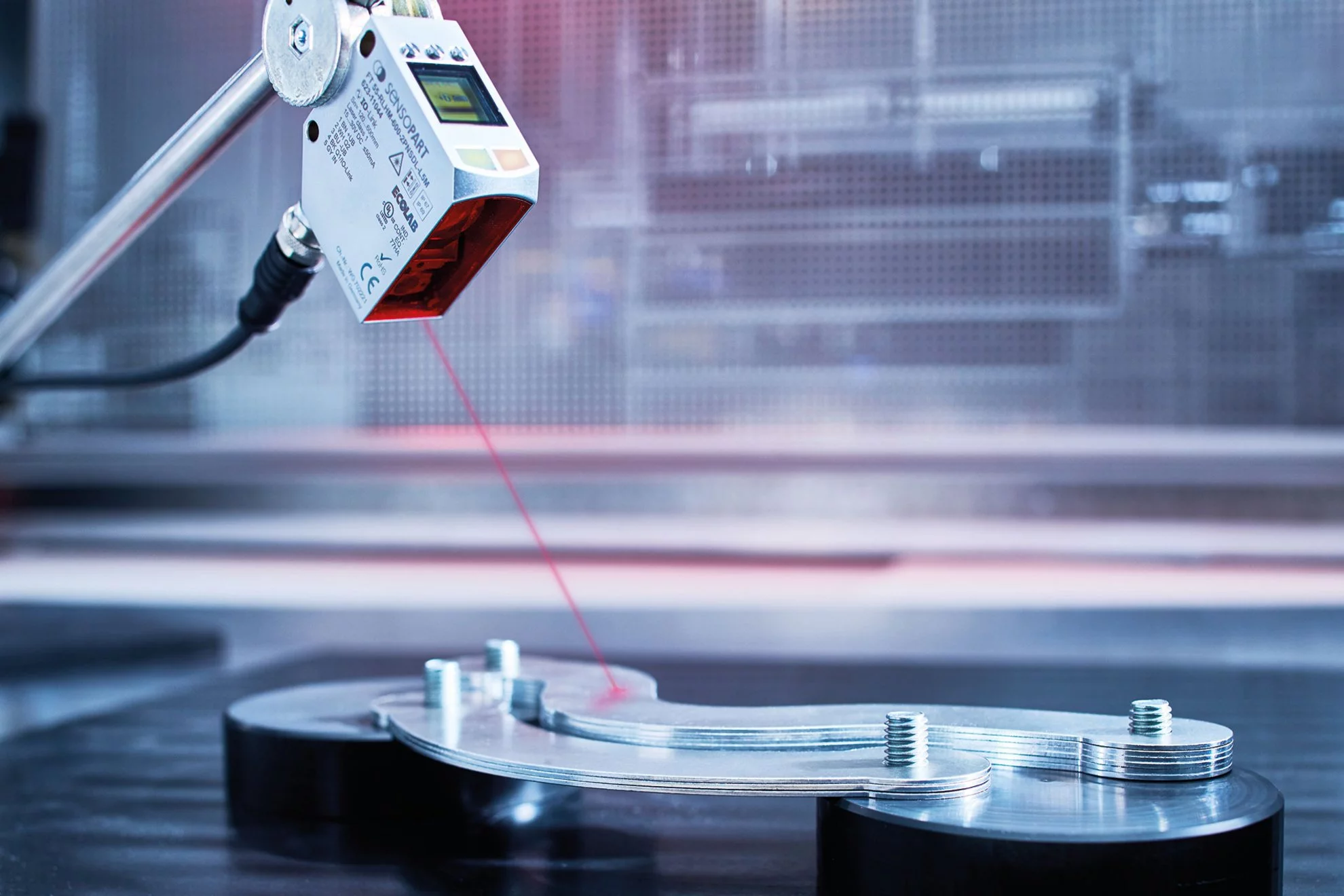

Magnetostrictive Strain Sensors

Magnetostrictive sensors use the property of certain materials to change their magnetic properties under strain. A magnetostrictive material, such as nickel or iron, is used in these sensors. When strain is applied, the material experiences changes in its magnetic field, which can be measured using appropriate techniques to determine the applied strain. Magnetostrictive strain sensors are used in applications such as structural health monitoring and non-destructive testing.

Strain gauge load cells

Strain gauge load cells are one of the most commonly used force sensor types. They work on the principle of strain gauges, which are devices that change resistance when subjected to strain or deformation.

Strain gauge load cells are typically made up of a metal body or structure that undergoes deformation when a force is applied.

Inside the load cell, one or more strain gauges are attached to the surface that experiences the strain.

When a force is applied to the load cell, it causes the metal body to deform slightly. This deformation results in a change in the electrical resistance of the strain gauge(s).

The strain gauges are connected in a Wheatstone bridge configuration, which is an electrical circuit that measures small changes in resistance. As the applied force causes the resistance of the strain gauge(s) to change, it creates an imbalance in the Wheatstone bridge circuit.

The imbalance in the bridge circuit generates a small electrical signal proportional to the applied force. This signal is then amplified and converted into a usable form, such as voltage or current, by the load cell’s electronics.

Before using a strain gauge load cell, it needs to be calibrated by applying known forces and measuring the corresponding output signals. This calibration process ensures accurate and reliable force measurements.

Strain sensors have a wide range of industrial applications, including structural monitoring, load measurement, robotics, aerospace, automotive, and civil engineering.

In all cases, the output from the strain sensor is an electrical signal that can be further processed, amplified, and analyzed to monitor and measure the strain or deformation of the object being measured.