Humidity sensors detect and measure the amount of moisture in the air or in a substance, and are commonly used in HVAC systems and food storage.

Humidity refers to the amount of moisture or water vapor present in the air. It is a measure of the atmospheric moisture content and plays an important role in our daily lives and the environment around us.

A humidity sensor, also known as a hygrometer, is a device used to measure and monitor the moisture content or humidity level in the surrounding air. It provides valuable data for various applications, such as weather monitoring, HVAC systems, greenhouse control, industrial processes, and indoor air quality management.

Humidity sensors types and their working principle

There are different types of humidity sensors available, including capacitive, resistive, and thermal conductivity sensors:

Capacitive humidity sensors

These sensors measure changes in the dielectric constant of a sensing material due to moisture absorption. The humidity level affects the capacitance of the sensor.

They work based on the principle of capacitance, which is the ability of a material to store an electrical charge. These sensors consist of a sensing element made of a moisture-absorbing material, usually a polymer or metal oxide, and two electrodes.

A capacitor creates an electric field between two conductive plates when the voltage is applied.

Capacitance (C) means the ability of a capacitor to accumulate electric charging (depending on the voltage). It is the effect of the combination of the area of overlap (A) on the two plates (in square meters), “d” the separation between the plates (in meters) and “ɛ” the relative permittivity (a.k.a. the dielectric constant) of the material.

The capacitance (C) can be measured through the following formula:

When humidity changes, the sensing element absorbs or releases moisture, which in turn affects its dielectric properties. As the dielectric properties change, the capacitance of the sensor also changes. By measuring this change in capacitance, the sensor can determine the relative humidity in the surrounding environment.

Capacitive humidity sensors are popular because they offer several advantages, such as high accuracy, fast response time, wide measurement range, and low power consumption. They are commonly used in various applications, including weather stations, HVAC systems, industrial processes, agriculture, and consumer electronics.

Capacitive humidity sensors may require periodic calibration to maintain accuracy over time. Additionally, they can be affected by contaminants, such as dust or chemicals, which may impair their performance. Regular cleaning and maintenance are recommended to ensure reliable readings.

Advantages and disadvantages of capacitive humidity sensors:

Capacitive humidity sensors, offer several advantages and disadvantages:

Advantages:

1. High Accuracy: Capacitive humidity sensors can provide accurate and precise measurements of relative humidity. They are sensitive to even small changes in humidity levels.

2. Fast Response Time: These sensors have a quick response time, allowing for real-time monitoring and control of humidity levels.

3. Low Power Consumption: Capacitive humidity sensors require low power to operate, making them suitable for battery-powered applications or environments with limited power availability.

4. Wide Measurement Range: They can measure a wide range of humidity levels, typically from 0% to 100% relative humidity.

Disadvantages:

1. Sensitivity to Contaminants: Capacitive humidity sensors can be affected by contaminants like dust, oils, and other particles. These contaminants can adhere to the sensor surface and interfere with its accuracy.

2. Limited Temperature Range: Some capacitive humidity sensors have limitations when it comes to extreme temperature conditions. High or low temperatures outside their specified operating range can affect their accuracy.

3. Calibration Requirements: To maintain accurate readings, capacitive humidity sensors often require periodic calibration. This additional step may increase maintenance efforts and costs.

4. Higher Cost: Compared to other types of humidity sensors, capacitive humidity sensors tend to be more expensive. However, their accuracy and performance justify the cost for many applications.

Resistive humidity sensors

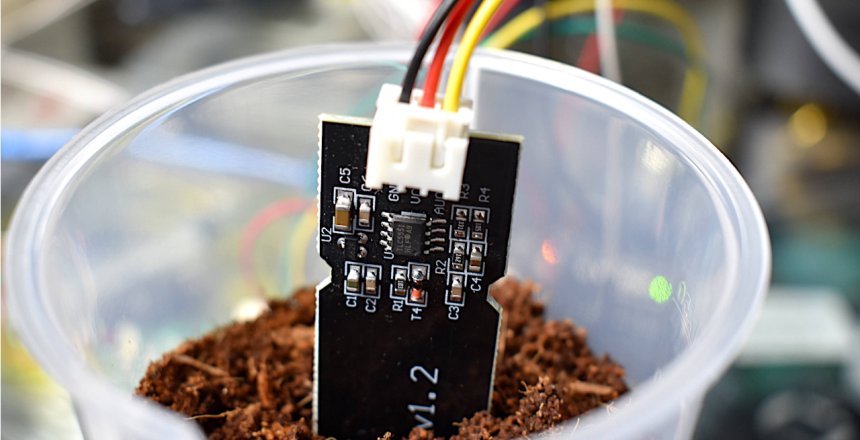

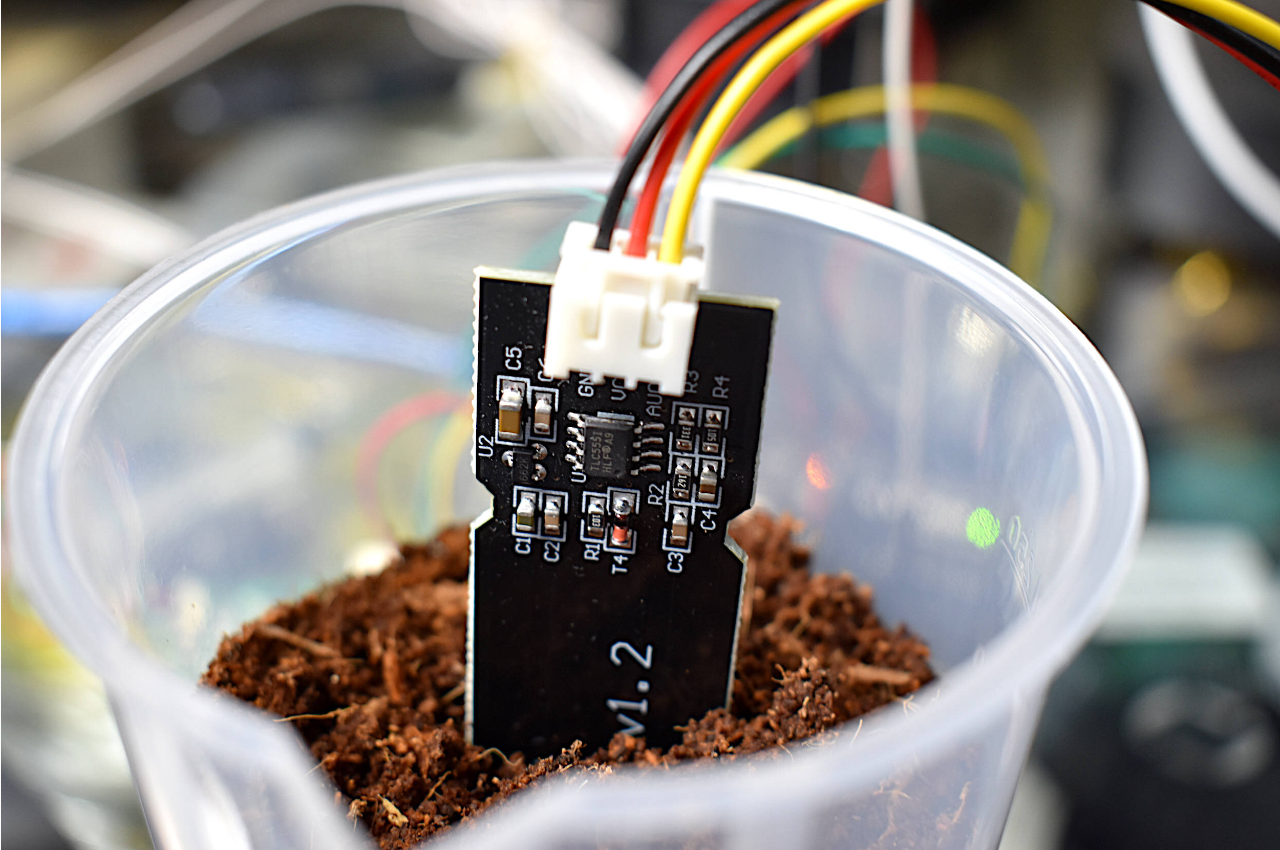

Resistive humidity sensors, also known as resistive hygrometers (RH sensors), are electronic devices that measure relative humidity based on changes in electrical resistance. These sensors consist of a moisture-sensitive material, such as a polymer or ceramic or salt-based materials, that changes its conductivity (electrical resistance) in response to changes in humidity. The resistance change is then measured to determine the humidity level.

Resistive humidity sensors are inexpensive but may have slower response times and lower accuracy compared to capacitive sensors.

The resistive humidity sensors working principle is based on the fact that the conductivity in non-metallic conductors is dependent on their water content.

The Resistive Humidity Sensor is usually made up of materials with relatively low resistivity and this resistivity changes significantly with changes in humidity.

The relationship between resistance and humidity is inverse exponential. The low resistivity material is deposited on top of two electrodes.

When the humidity increases, the moisture-sensitive material absorbs moisture, causing it to swell and increase its conductivity. Conversely, as humidity decreases, the material loses moisture and its conductivity decreases. By measuring the resistance across the sensor, one can determine the relative humidity in the surrounding environment.

Resistive humidity sensors offer several advantages, including low cost, simplicity, and robustness. They are commonly used in industrial and consumer applications, such as HVAC systems, incubators, automotive systems, and weather monitoring.

However, they are typically less accurate and slower in response compared to capacitive humidity sensors. In addition, resistive humidity sensors may exhibit hysteresis, meaning their readings may vary depending on whether humidity is increasing or decreasing.

Advantages and disadvantages of resistive humidity sensors:

Resistive humidity sensors, also known as resistive relative humidity sensors or hygrometers, have their own set of advantages and disadvantages:

Advantages:

1. Cost-Effective: Resistive humidity sensors are generally more affordable compared to other types of humidity sensors, making them a cost-effective choice for many applications.

2. Simple Design: These sensors have a relatively simple design, which makes them easy to manufacture and integrate into various electronic systems.

3. Wide Operating Range: Resistive humidity sensors can operate effectively across a wide range of humidity levels, typically from 0% to 100% relative humidity.

4. Long-Term Stability: They exhibit good long-term stability, meaning they retain their accuracy over an extended period without requiring frequent recalibration.

5. Low Power Consumption: Resistive humidity sensors typically consume low power, making them suitable for battery-powered devices and applications.

Disadvantages:

1. Lower Accuracy: Compared to other types of humidity sensors, resistive humidity sensors have lower accuracy. They may have larger measurement errors and lower resolution, especially at extreme humidity levels.

2. Slow Response Time: These sensors generally have a slower response time compared to capacitive or optical humidity sensors. They may take longer to provide accurate readings, which could be a disadvantage in some real-time monitoring applications.

3. Susceptible to Interference: Resistive humidity sensors are sensitive to interference from contaminants such as dust, oils, and other particles. These contaminants can affect the accuracy of the readings.

4. Temperature Dependence: The resistance of resistive humidity sensors can be affected by temperature variations. It is essential to account for temperature changes when using these sensors to ensure accurate humidity measurements.

Despite these limitations, resistive humidity sensors can still be suitable for many applications where high accuracy and fast response time are not critical requirements or when cost-effectiveness is a priority.

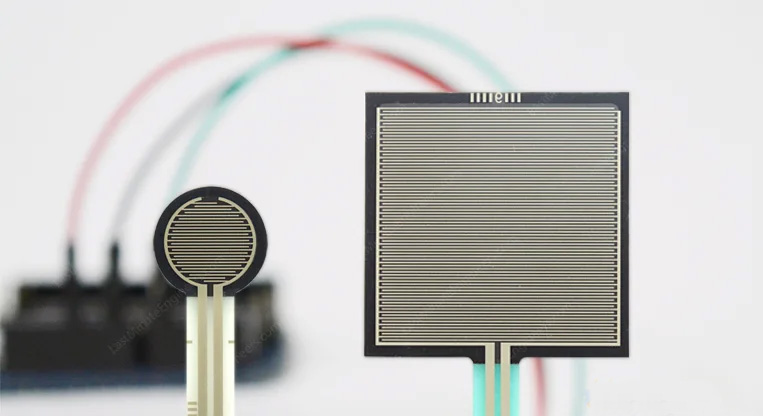

Thermal conductivity humidity sensors

These sensors involve two temperature-sensitive elements-one exposed to ambient air and the other kept at a constant temperature reference. Moisture absorption affects the thermal conductivity between the two elements, allowing the sensor to determine humidity levels. Thermal conductivity sensors are reliable and have excellent long-term stability but can be costlier.

Two NTC thermistors are used in the structure of these sensors. One of the thermistors is placed in a chamber that is exposed to the air through a series of ventilation holes. The second thermistor is placed in a different chamber within the sensor that is hermetically sealed in dry nitrogen. An electrical bridge circuit passes current to the thermistors which begin to self-heat. Since one of the thermistors is exposed to humidity from the air, it

will have different conductivity. A measurement of the difference in resistance of the two thermistors can be made which will be directly proportional to the absolute humidity.

Thermal conductivity humidity sensors offer several advantages, such as high accuracy, fast response time, and low power consumption. They are widely used in various applications, including indoor climate control, industrial processes, weather stations, and scientific research.

However, these sensors can be more expensive compared to resistive humidity sensors. They are also sensitive to contaminants and require regular calibration to maintain accurate readings.

Advantages and disadvantages of thermal conductivity humidity sensors:

Advantages:

1. Wide Dynamic Range: Thermal conductivity humidity sensors can accurately measure humidity across a wide range, typically from 0% to 100% relative humidity. This makes them suitable for various applications with different humidity levels.

2. Low Cost: Compared to other types of humidity sensors, thermal conductivity sensors are relatively inexpensive. This affordability makes them a cost-effective choice for applications with budget constraints.

3. Insensitivity to Contaminants: Thermal conductivity sensors are not easily affected by contaminants such as dust, oils, or other particulates. They can maintain their accuracy even in challenging environments with high levels of airborne particles.

4. Good Long-term Stability: Thermal conductivity humidity sensors offer excellent long-term stability. They are less prone to drift or aging, ensuring consistent and reliable humidity measurements over extended periods.

Disadvantages:

1. Lower Precision: Compared to some other types of humidity sensors, thermal conductivity sensors may have slightly lower precision in measuring humidity. The accuracy can be affected by factors like temperature variations or changes in gas composition.

2. Slower Response Time: These sensors typically have a slower response time compared to capacitive humidity sensors. They may take longer to adjust to rapid changes in humidity levels, making them less suitable for applications requiring immediate response.

3. Sensitivity to Temperature: Thermal conductivity humidity sensors can be influenced by temperature fluctuations. Variations in temperature can affect their accuracy and may require additional compensation techniques or temperature control measures.

4. Bulkier Size: Thermal conductivity sensors can be physically larger and bulkier compared to some other types of humidity sensors. This size factor might limit their use in applications with space constraints or where miniaturization is desired.

Thermal conductivity humidity sensors are commonly used in various industries, including HVAC systems, industrial process control, and environmental monitoring. Their cost-effectiveness, stability, and resistance to contaminants make them a reliable choice for many applications.