A temperature sensor is used to measure the temperature of an object or environment. It converts temperature into an electrical signal for interpretation.

Temperature sensors are devices that are used to measure temperature. They can be found in various applications, ranging from household appliances to industrial equipment. These sensors work by detecting changes in physical or electrical properties in response to temperature changes.

Temperature sensors work based on various principles depending on their type but regardless of the type of temperature sensor, they all convert the temperature into an electrical signal that can be measured and interpreted by data acquisition systems or controllers. The output signal can be analog (voltage or current) or digital, depending on the sensor type and interface requirements.

Temperature sensors based on their physical types

There are many various types of Temperature Sensors available, and all have different features based on their application But Temperature sensors can be divided into two general categories based on their physical types:

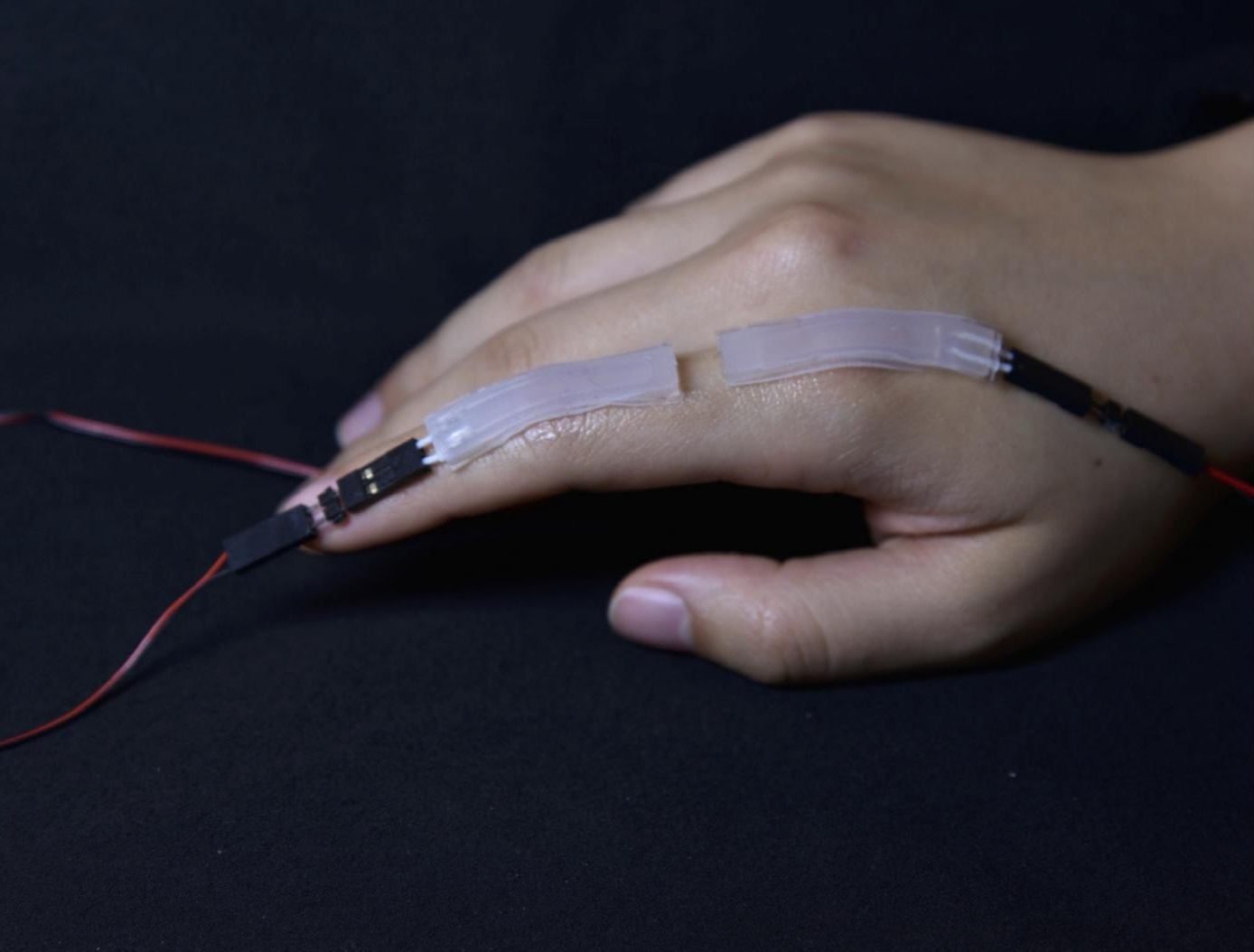

Contact temperature sensor types

Contact temperature sensors require physical contact with the object being measured. They directly sense the temperature of the object by making contact with it. Examples of contact temperature sensors include thermocouples, resistance temperature detectors (RTDs), and thermistors. These sensors are commonly used in applications where precise and accurate temperature readings are required.

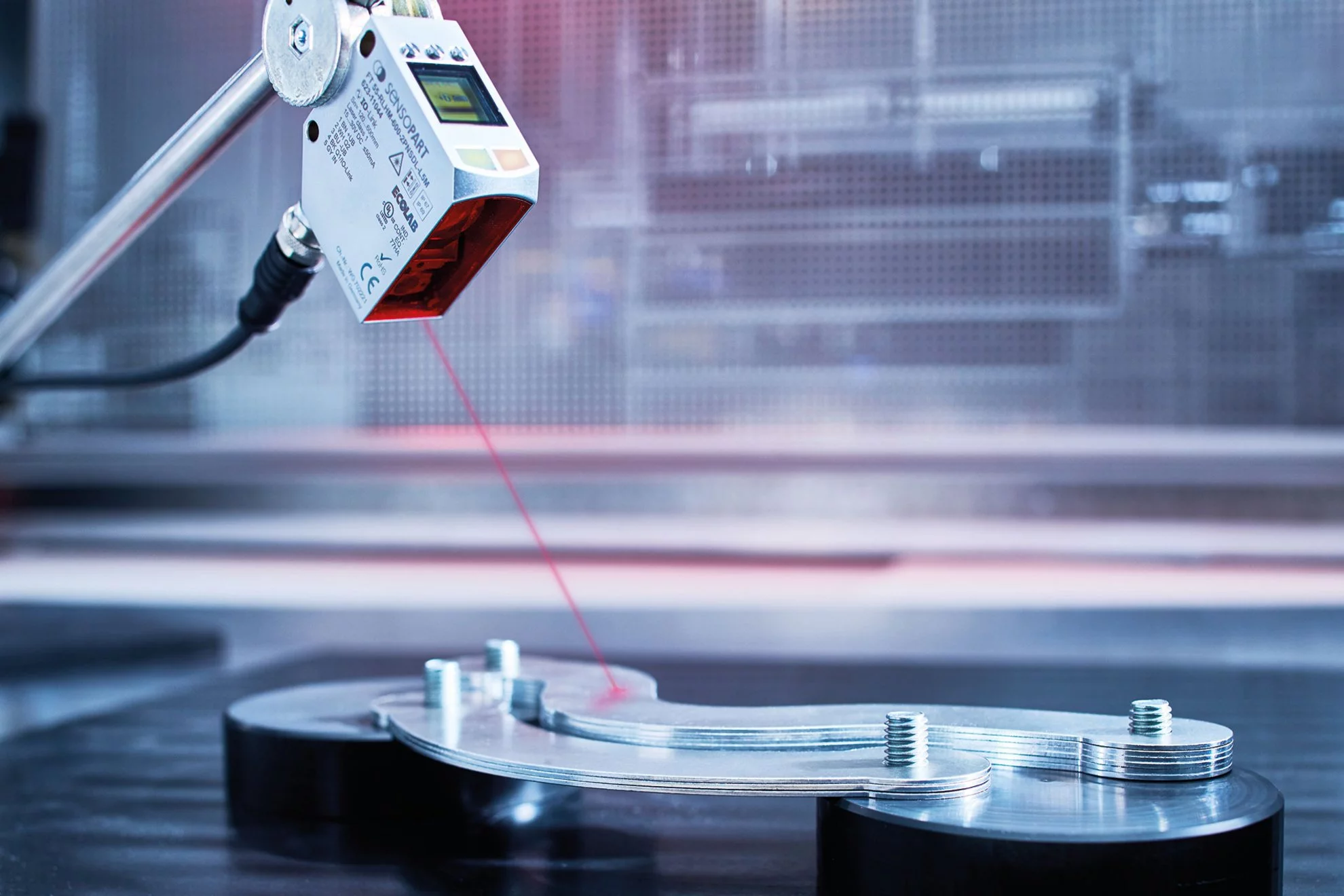

Non-contact temperature sensor types

Non-contact temperature sensors, on the other hand, do not require physical contact with the object being measured. Instead, they measure the temperature from a distance by sensing the thermal radiation emitted by the object. Infrared (IR) sensors, and fiber optic temperature sensors are examples of non-contact temperature sensors. These sensors are often used in applications where the object may be moving, inaccessible, or at an extreme temperature.

Contact temperature sensors provide direct and accurate measurements but require placement directly on the object being measured. Non-contact temperature sensors, on the other hand, offer the advantage of remote sensing and can measure temperature without physically touching the object. The choice between contact and non-contact sensors depends on factors such as measurement accuracy, object accessibility, temperature range, and application requirements.

Different types of temperature sensor based on their sensing type

There are different types of temperature sensors available, each with its own advantages and disadvantages. Some common examples include:

Thermocouples

Thermocouples are made of two dissimilar metals joined together. When there is a temperature difference between the junction (hot end) and the other end (cold end), They generate a voltage proportional to the temperature difference between the measurement junction and the reference junction. They are widely used for their durability, wide temperature range, and affordability.

Resistance temperature detectors (RTDs)

RTDs use the principle of electrical resistance change with temperature. are made of pure metals or alloys with a positive temperature coefficient of resistance, they are typically made from platinum,

which has a linear resistance-temperature relationship. As the temperature increases, the electrical resistance of the RTD also increases. This change in resistance can be correlated to the temperature using pre-calibrated tables or equations.

RTDs offer high accuracy, stability, and repeatability, making them suitable for various applications.

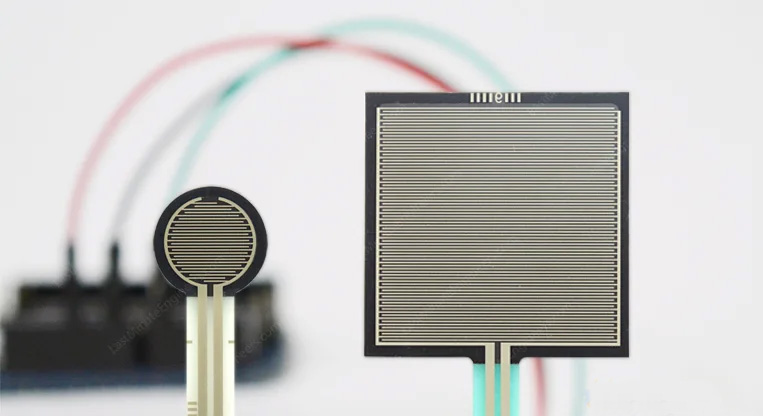

Thermistors

Thermistors are temperature-sensitive resistors made of semiconductor materials. The resistance change is used to determine the temperature. They have a non-linear resistance-temperature

relationship, with either positive(PTC) or negative(NTC) temperature coefficients. NTC thermistors decrease their resistance as the temperature increases, while PTC thermistors increase their resistance with increasing their

resistance with increasing temperature. Thermistors are cost-effective, highly sensitive, and available in small sizes.

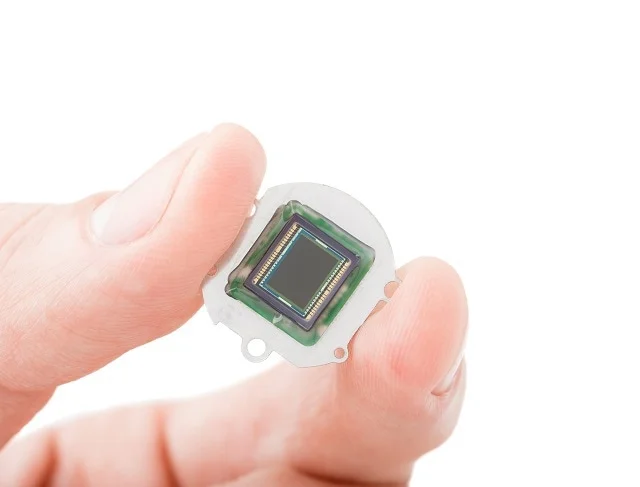

Infrared (IR) sensors

IR sensors detect and measure the thermal radiation emitted by objects. They utilize a detector that responds to the intensity of infrared radiation. The temperature is calculated based on the detected radiation and the sensor’s calibration curve.

Fiber optic sensors

Fiber optic sensors use the principle of light transmission through optical fibers to measure temperature. They can withstand harsh environments, electrical noise, and electromagnetic interference. Fiber optic sensors are commonly used in applications requiring high accuracy and immunity to electrical interference.

These are just a few examples of temperature sensors, each with its own advantages and applications. The choice of sensor depends on factors such as temperature range, accuracy requirements, response time, cost, and environmental conditions.

Temperature sensors applications

As it was said temperature sensors are used in a wide range of applications across various industries. Here are some common uses of temperature sensors:

HVAC systems

Temperature sensors play a crucial role in heating, ventilation, and air conditioning (HVAC) systems. They monitor the ambient temperature and provide feedback to control heating or cooling equipment, ensuring comfortable indoor environments.

Weather monitoring

Temperature sensors are employed in weather stations and meteorological instruments to measure ambient air temperature. These measurements are crucial for weather forecasting, climate analysis, and environmental monitoring.

Industrial processes

Temperature sensors are extensively used in industrial processes to monitor and control temperature parameters. They enable precise temperature regulation in manufacturing, chemical, pharmaceutical, and food processing industries, among others.

Automotive applications

Temperature sensors are essential components in automotive systems. They monitor engine coolant temperature, exhaust gas temperature, and cabin temperature to ensure optimal performance, prevent overheating, and provide comfort to passengers.

Medical devices

Temperature sensors are used in medical equipment such as thermometers, incubators, and patient monitoring devices. They help measure and regulate body or ambient temperatures for diagnostic and therapeutic purposes.

Food safety

Temperature sensors are employed in food storage and transportation systems. They monitor the temperature of refrigerators, freezers, and cold storage units to ensure food safety and prevent spoilage.

Energy efficiency

Temperature sensors are used in building automation systems to optimize energy efficiency. They help regulate heating, cooling, and lighting systems based on real-time temperature data, reducing energy consumption and costs.

Consumer electronics

Temperature sensors are present in various consumer electronic devices like smartphones, laptops, and smart thermostats. They help prevent overheating and maintain optimal operating conditions for efficient performance and user safety.

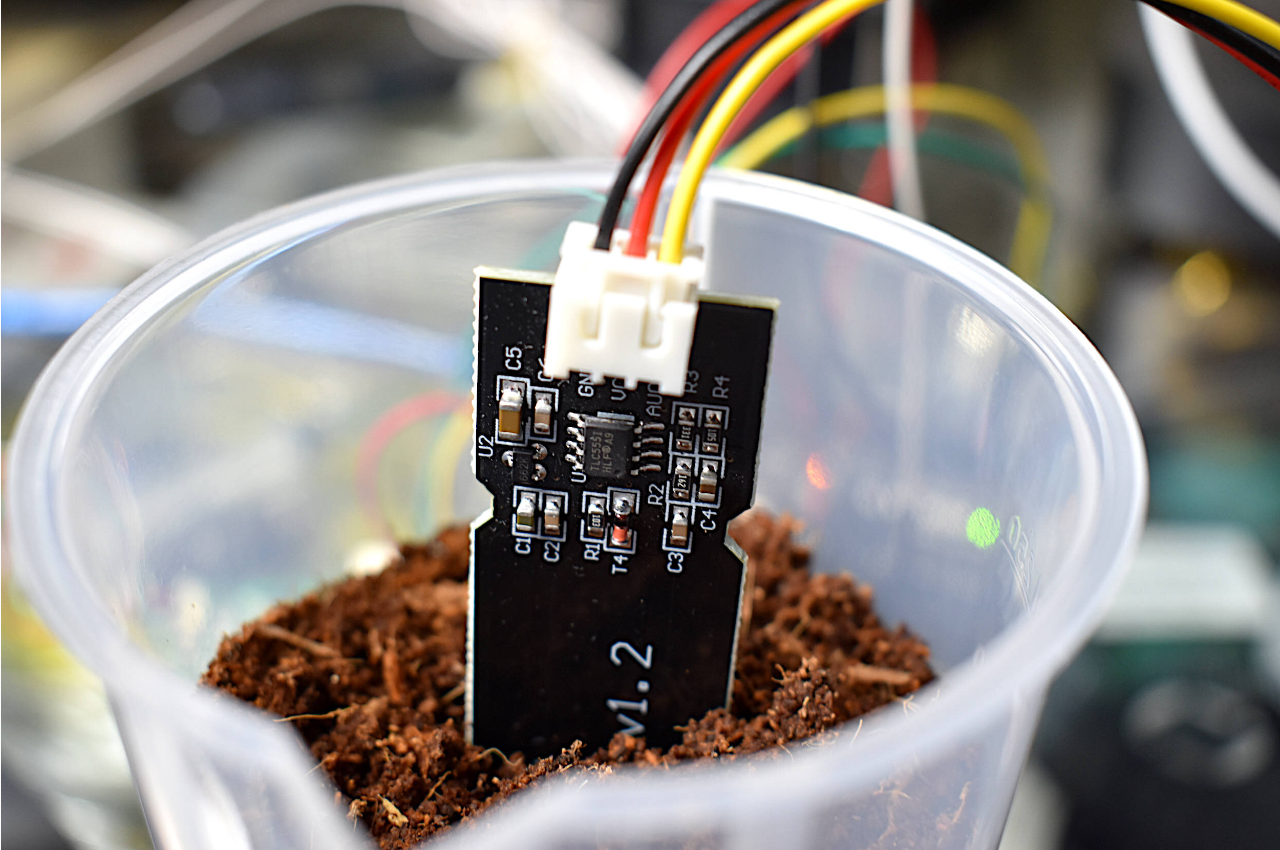

Agriculture

Temperature sensors are used in agriculture to monitor soil temperature, air temperature, and

greenhouse temperatures. This information helps farmers optimize plant growth conditions and protect crops from extreme temperatures.

These are just a few examples of the diverse applications of temperature sensors. Their ability to accurately measure temperature is crucial for maintaining safety, efficiency, and optimal performance in numerous industries and everyday life.

Considerations when selecting a temperature sensor

When selecting a temperature sensor, there are several considerations to keep in mind. These factors can help ensure the sensor is suitable for your specific application and provides accurate and reliable temperature measurements. Here are some key considerations:

Temperature range

Determine the temperature range within which the sensor will be used. Different sensors have different operating temperature ranges, so choose one that can accurately measure temperatures within your desired range.

Accuracy

Consider the required level of accuracy for your application. Different sensors have varying levels of accuracy, so choose one that meets your accuracy requirements.

Response time

Evaluate the response time of the sensor. This refers to how quickly the sensor can detect and report changes in temperature. Some applications may require a rapid response time, while others may tolerate slower response times.

Environmental conditions

Assess the environmental conditions in which the sensor will be deployed. Consider factors such as humidity, pressure, vibration, and exposure to chemicals or corrosive substances. Ensure that the sensor is designed to withstand these conditions.

Cost

Different types of sensors and brands may have different price points. Make sure to consider the long-term costs, including maintenance and calibration, in addition to the initial purchase cost.

Calibration

Determine if the sensor requires periodic calibration to maintain accuracy. Some sensors may drift over time and need recalibration. Understand the calibration requirements and factor them into your decision-making process.

Power requirements

Consider the power supply available for the sensor. Some temperature sensors may require a specific voltage or current input. Ensure that the power requirements of the sensor align with the available power source.

Compatibility

Ensure that the temperature sensor is compatible with the data acquisition system or controller you will be using. Check for compatibility in terms of communication protocols, signal conditioning requirements, and interface options.

By considering these factors, you can choose a temperature sensor that meets your specific needs, ensuring accurate and reliable temperature measurements for your application.

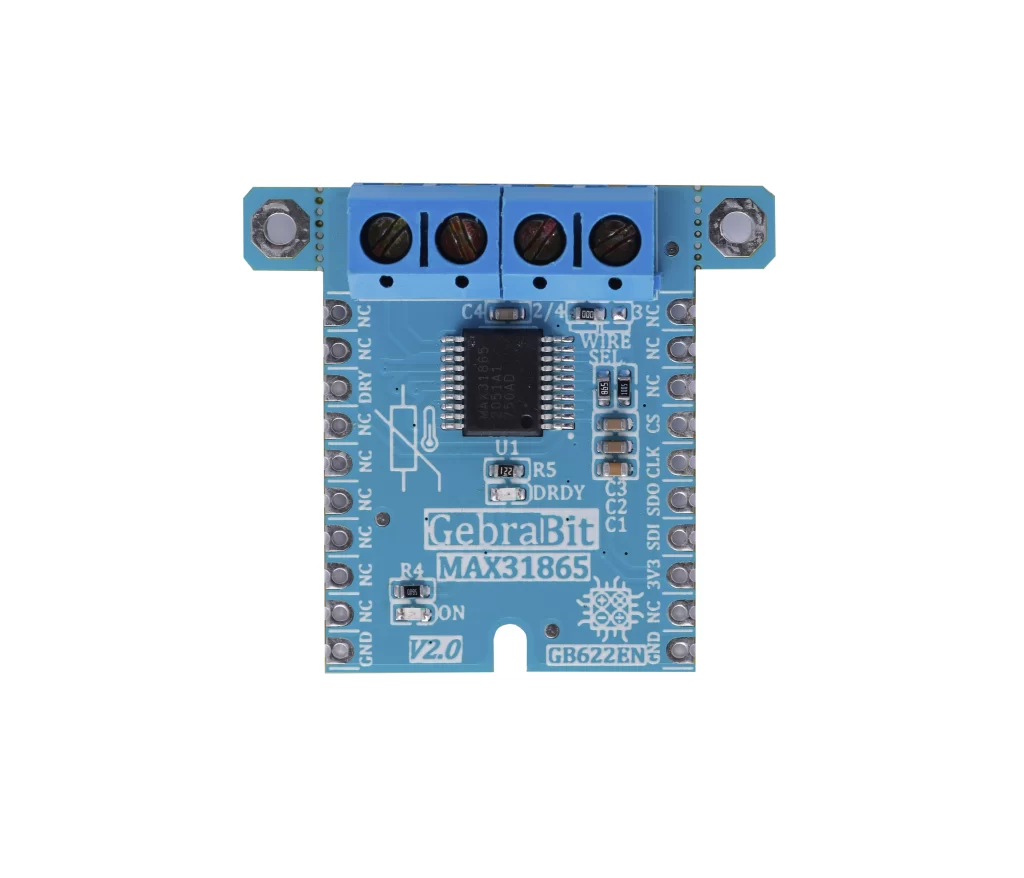

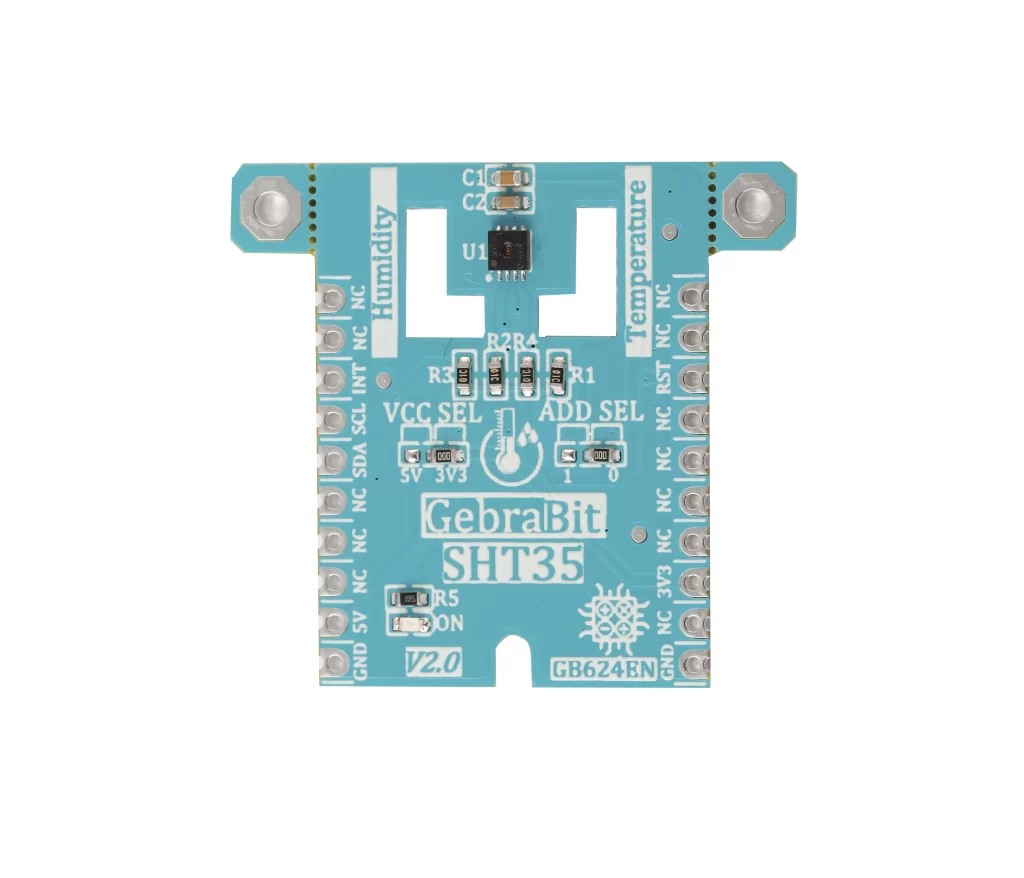

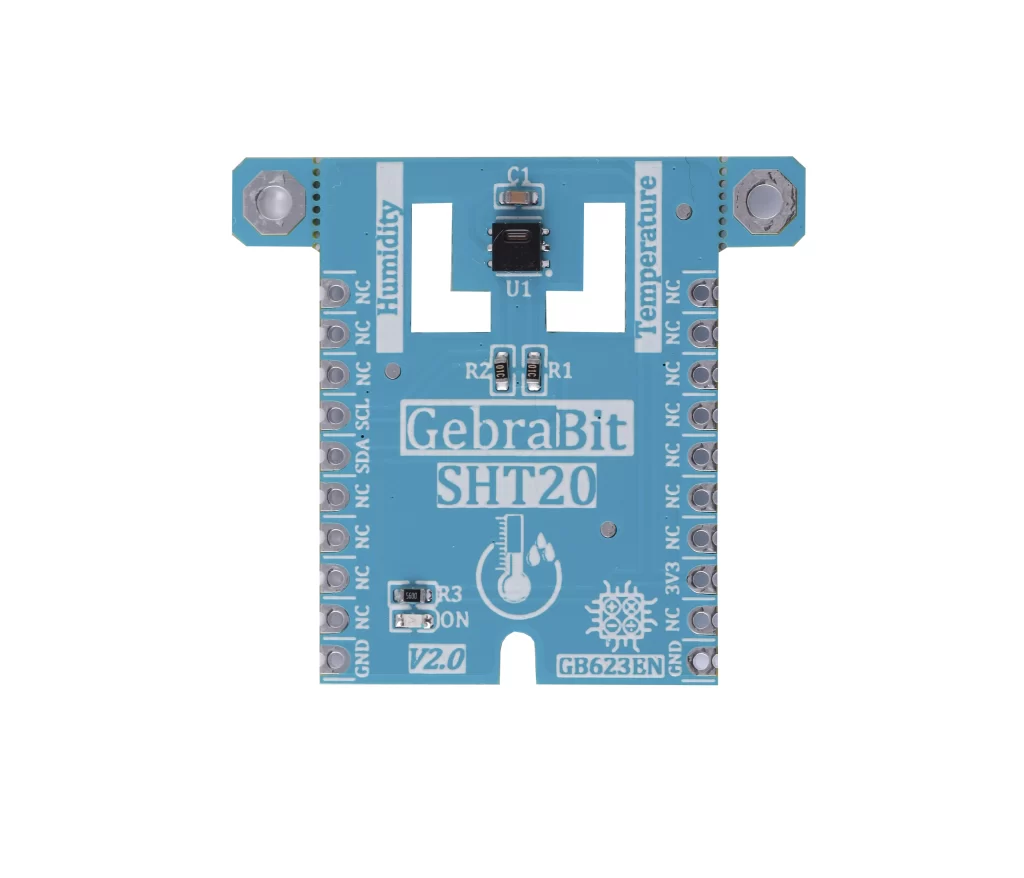

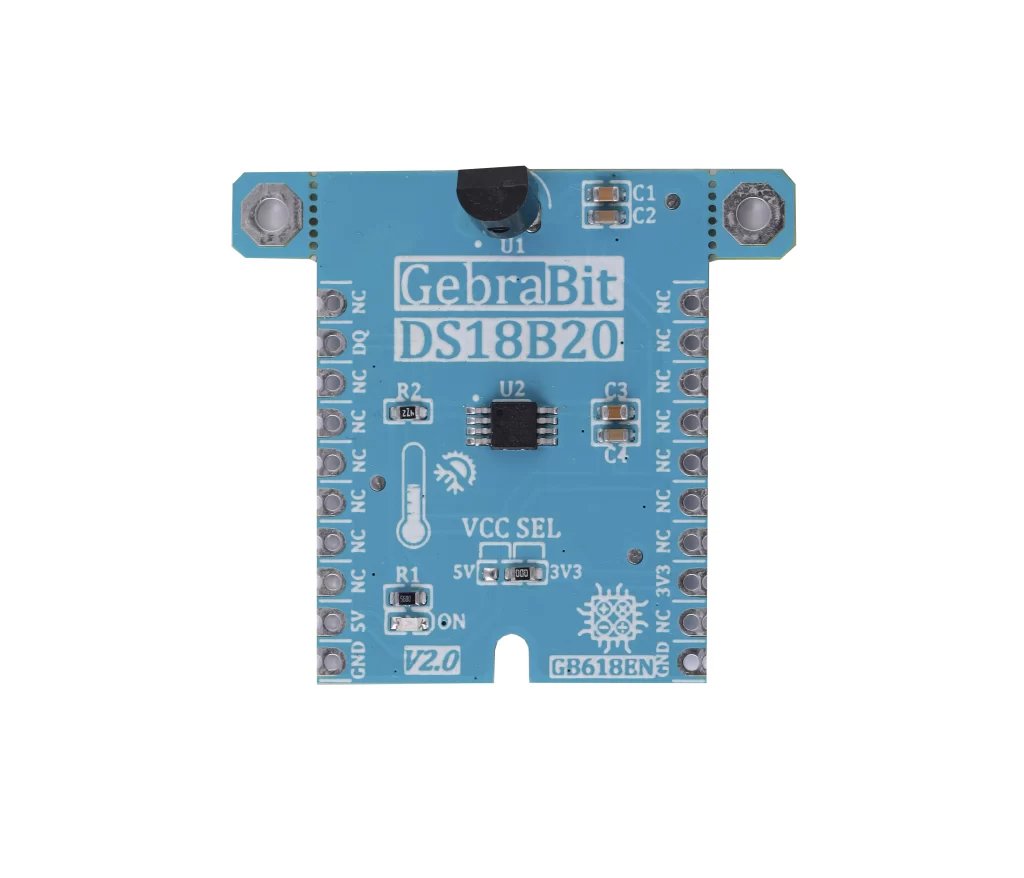

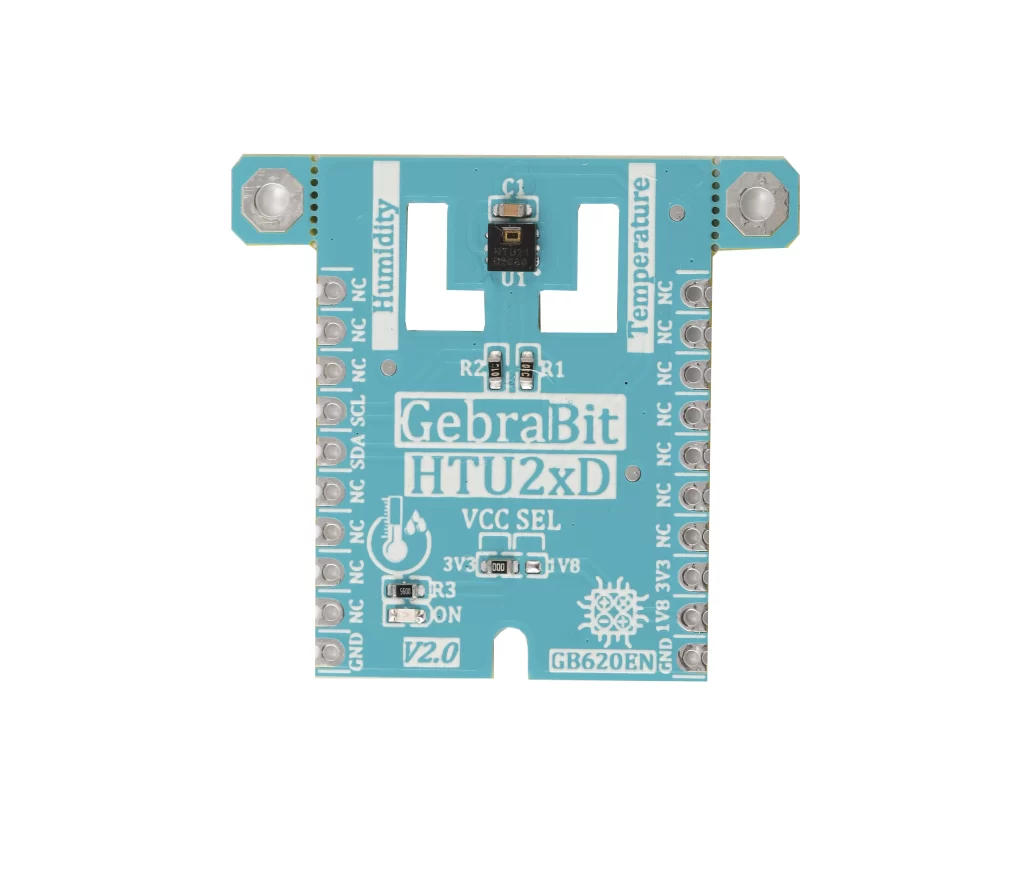

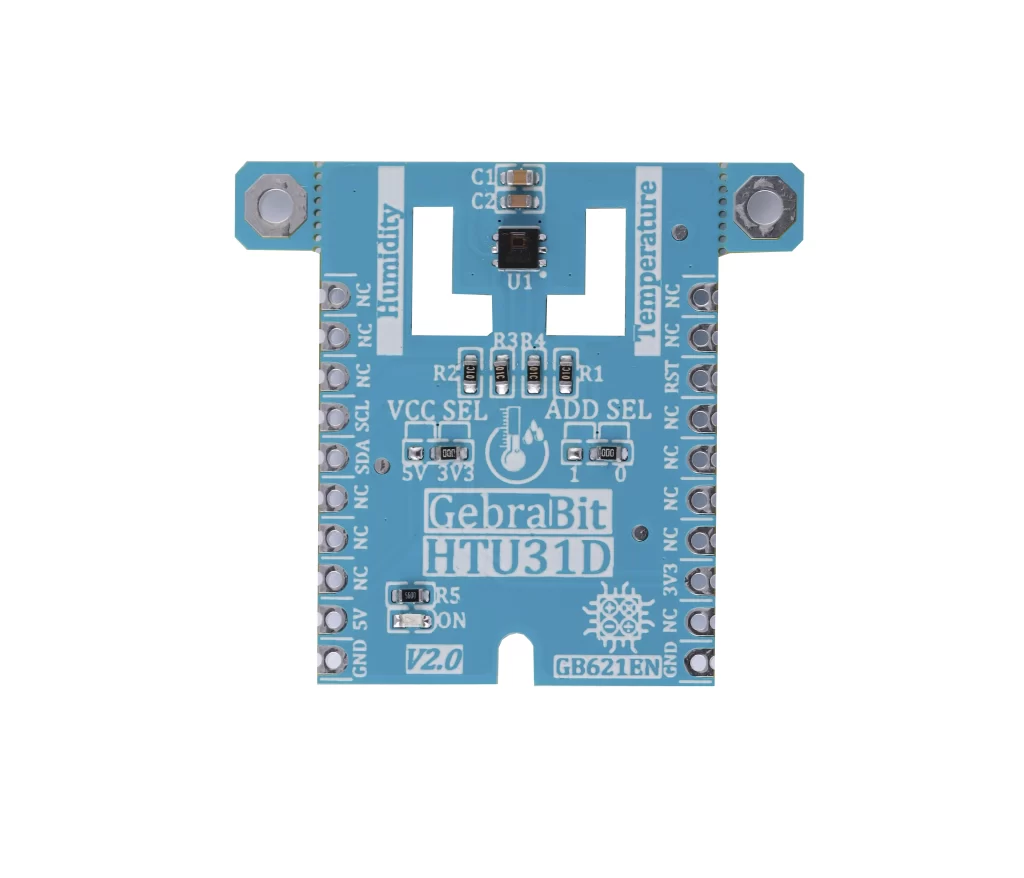

GebraBit Temperature Sensors

Here are the temperature sensors made by GebraBit team to ease your work. You can read about each of them by clicking on its title