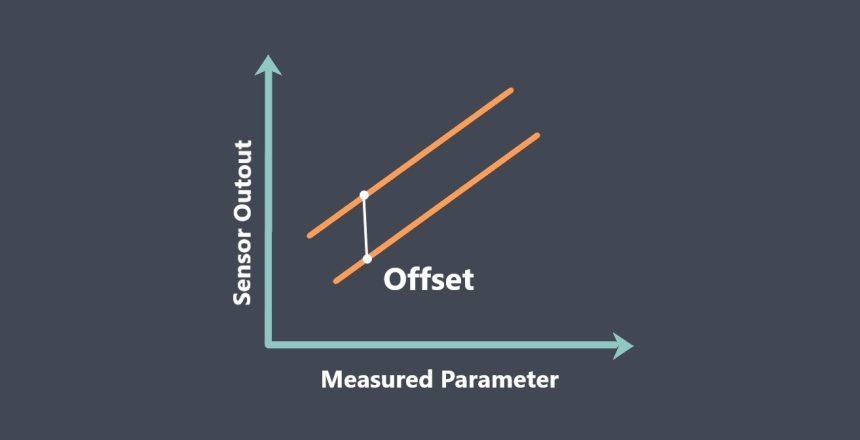

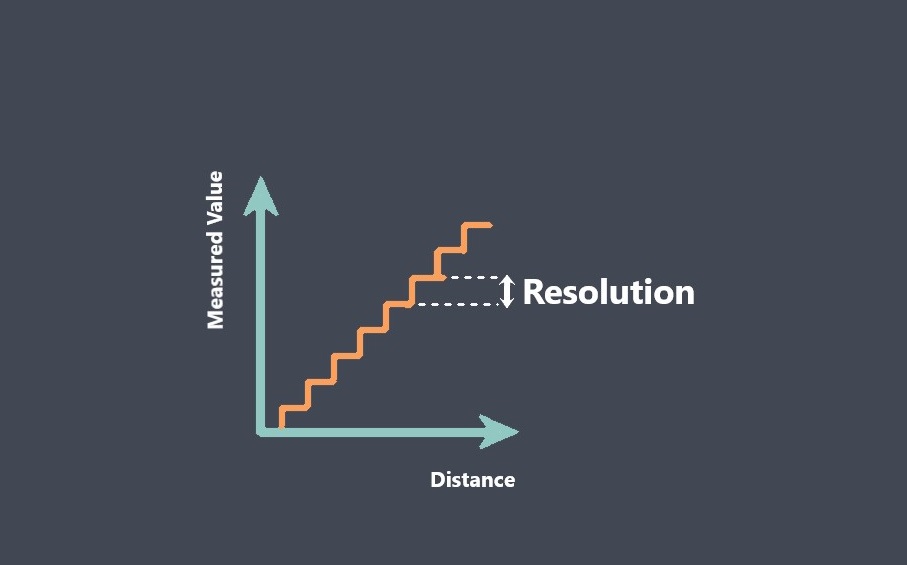

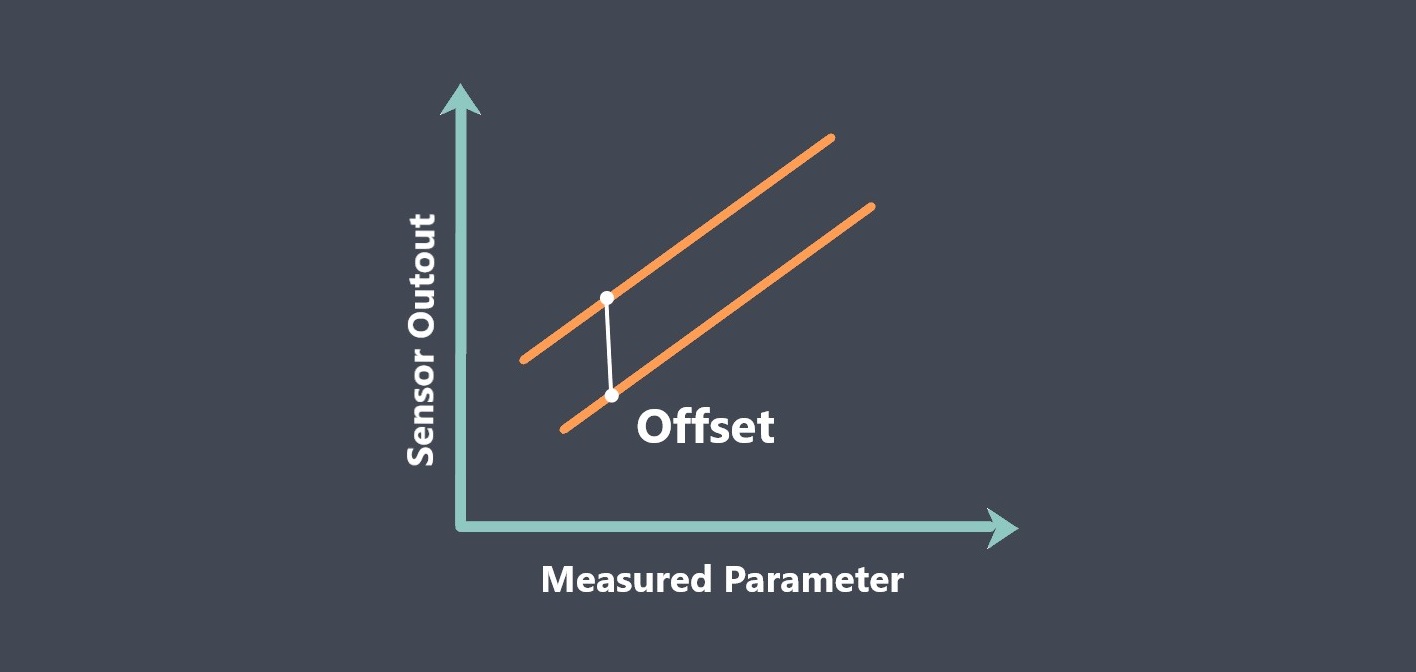

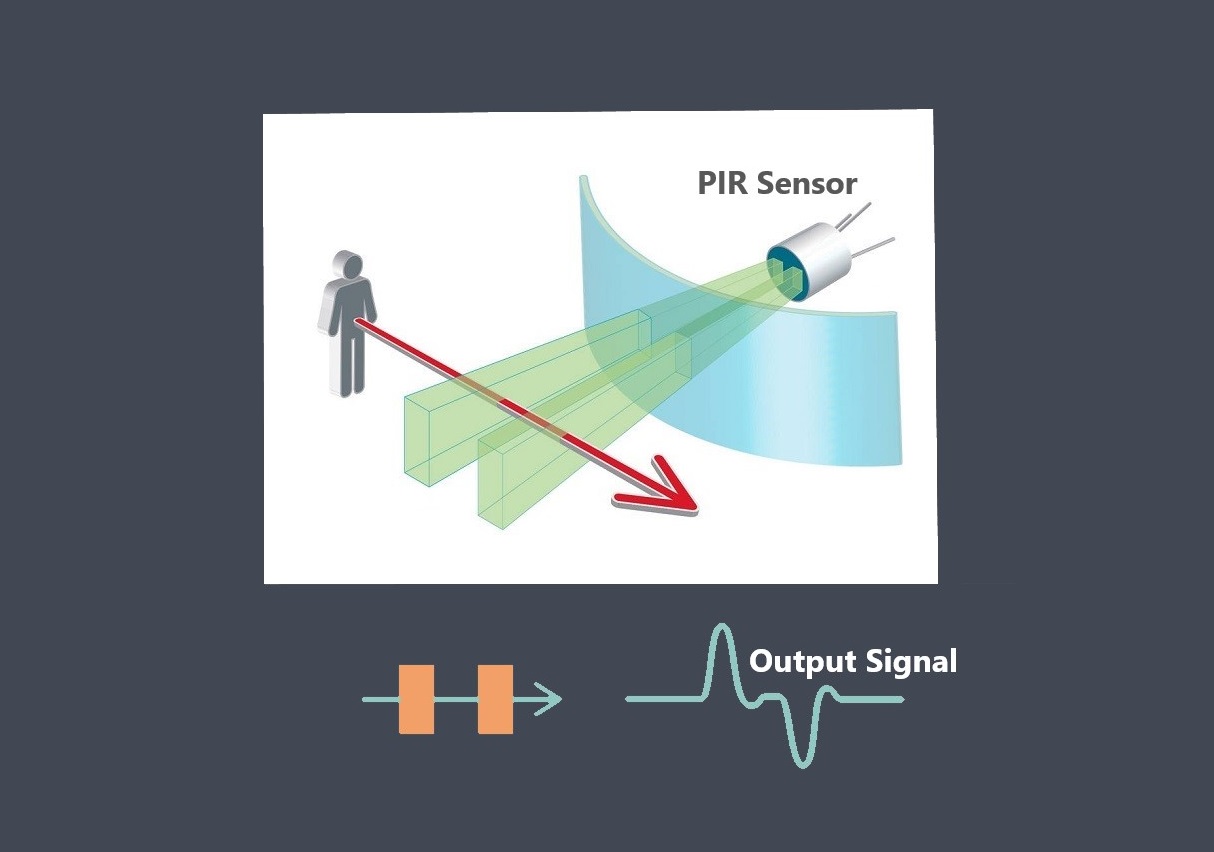

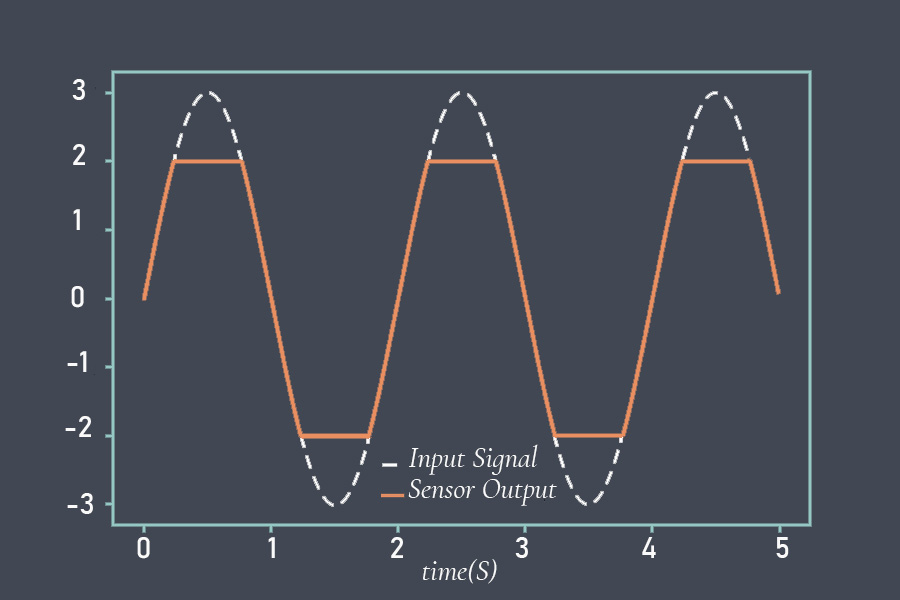

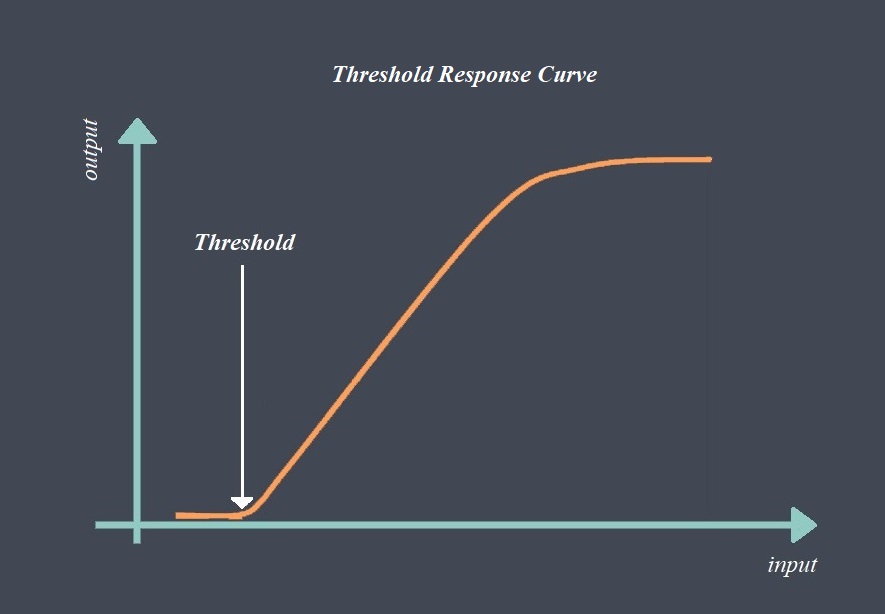

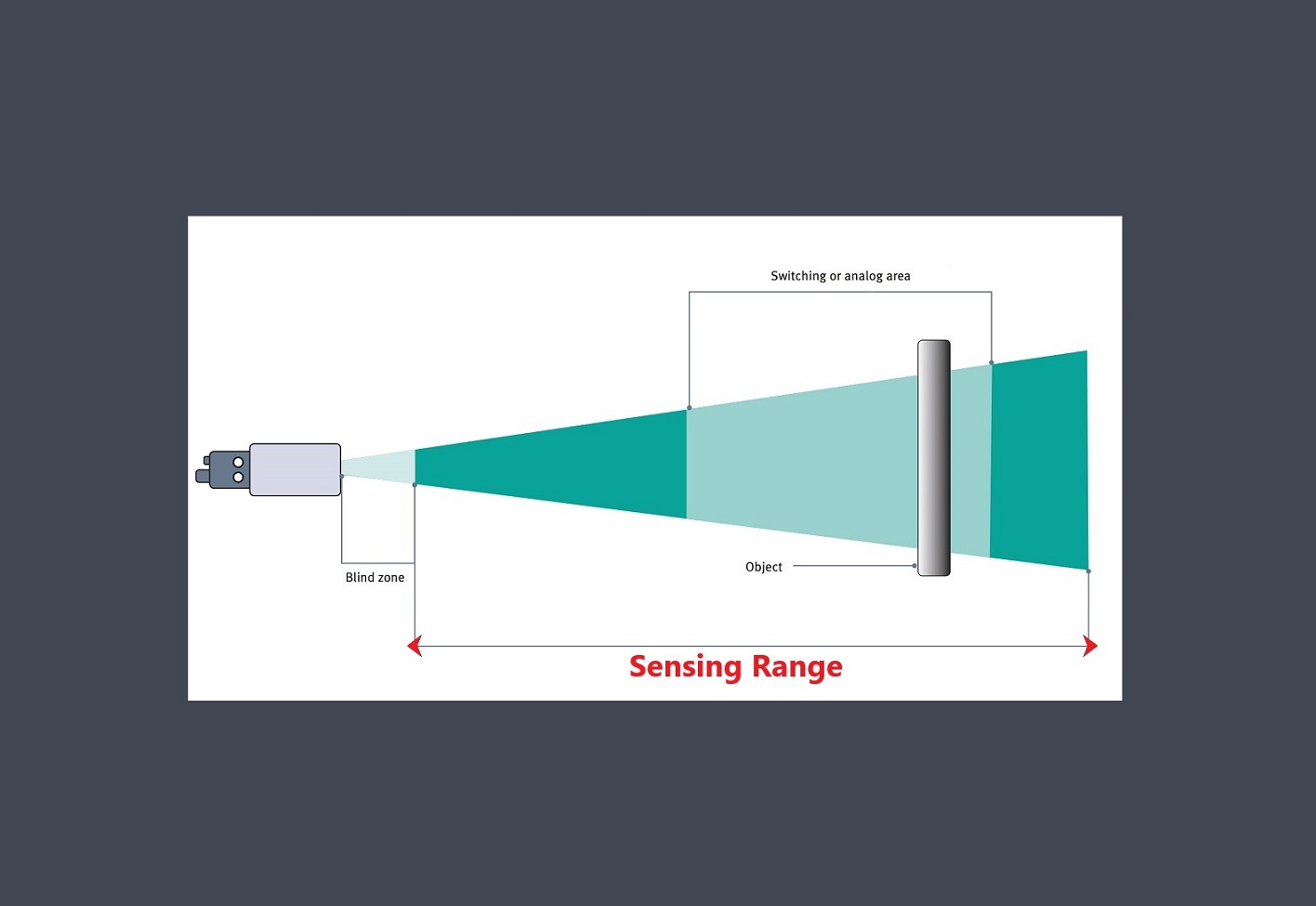

Offset is an important parameter in sensor technology that describes the deviation between the sensor’s output at zero input and the expected output value. It represents an inherent bias or shift in the output signal of the sensor, even when the input signal is at its lowest or zero value.

Why is sensor offset important?

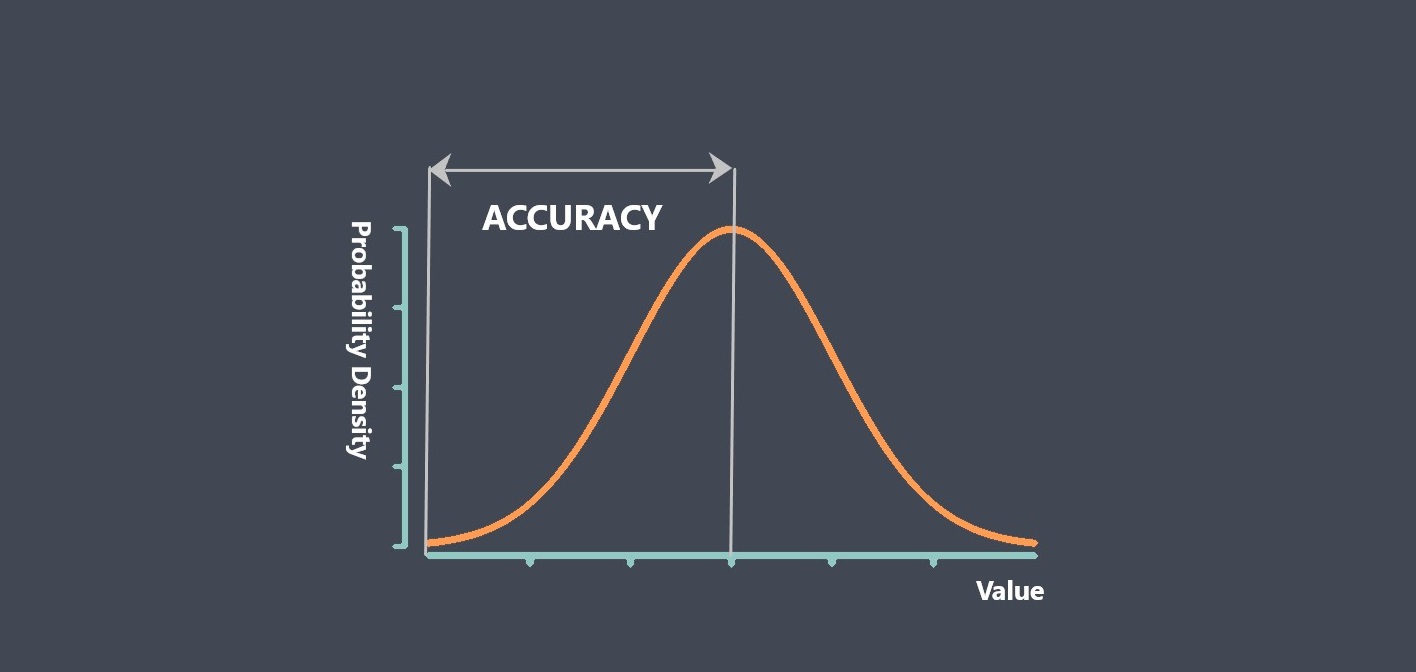

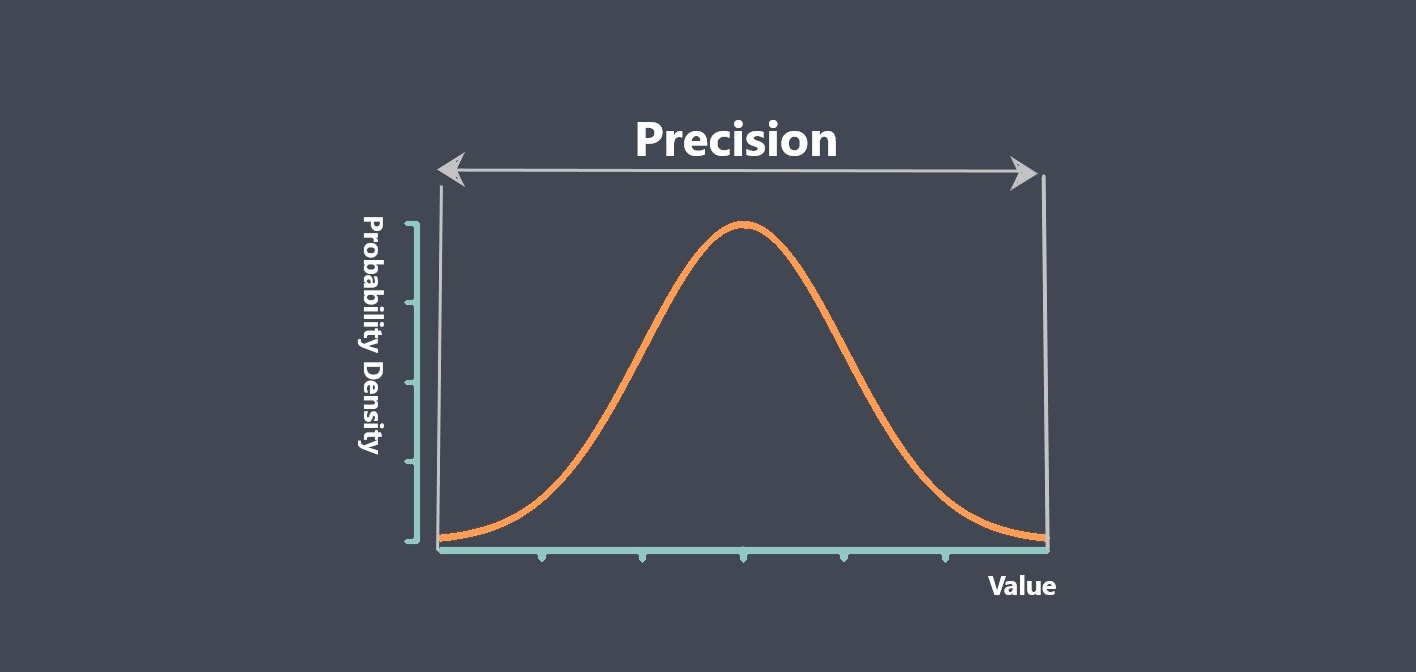

Sensor offset is important because it directly affects the accuracy and reliability of sensor measurements. Sensor offset refers to the deviation or bias in the sensor’s output readings from its true value or reference point.

Here are a few key reasons why sensor offset is important:

Accuracy

Sensor offset can introduce errors in the measurements obtained from sensors. If the offset is not properly accounted for, the readings will be consistently shifted away from the actual values. By calibrating and compensating for sensor offset, the measurements can be corrected to improve their accuracy.

Calibration

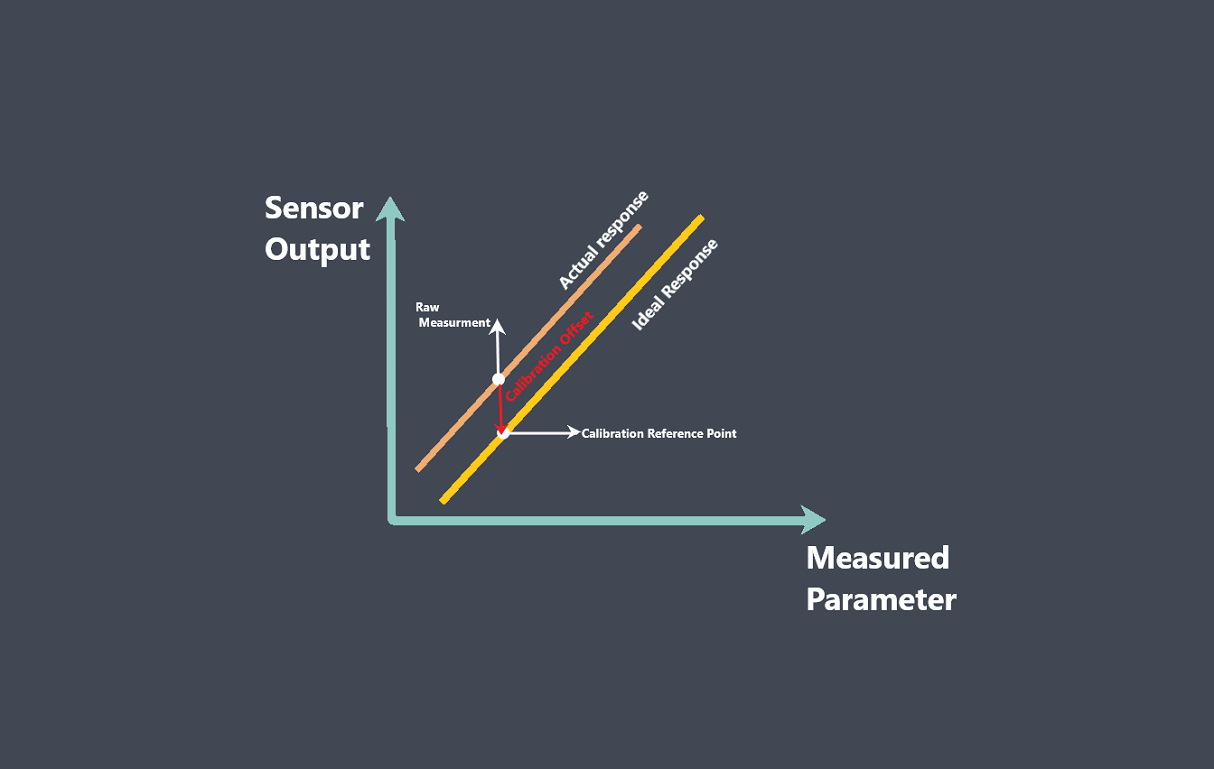

Calibration is the process of determining the relationship between the sensor’s output and the actual physical quantity being measured. Sensor offset is one of the factors considered during calibration. By accurately measuring and accounting for the offset, the calibration process can establish the necessary adjustments needed to obtain accurate results.

System Performance

In many systems, sensors are used as feedback devices to control various processes or operations. The accuracy of these control systems relies on precise measurements from the sensors. Sensor offset can potentially lead to inaccuracies in the control loop, affecting the overall system performance. By minimizing or compensating for sensor offset, the control system can operate more effectively.

Reliability

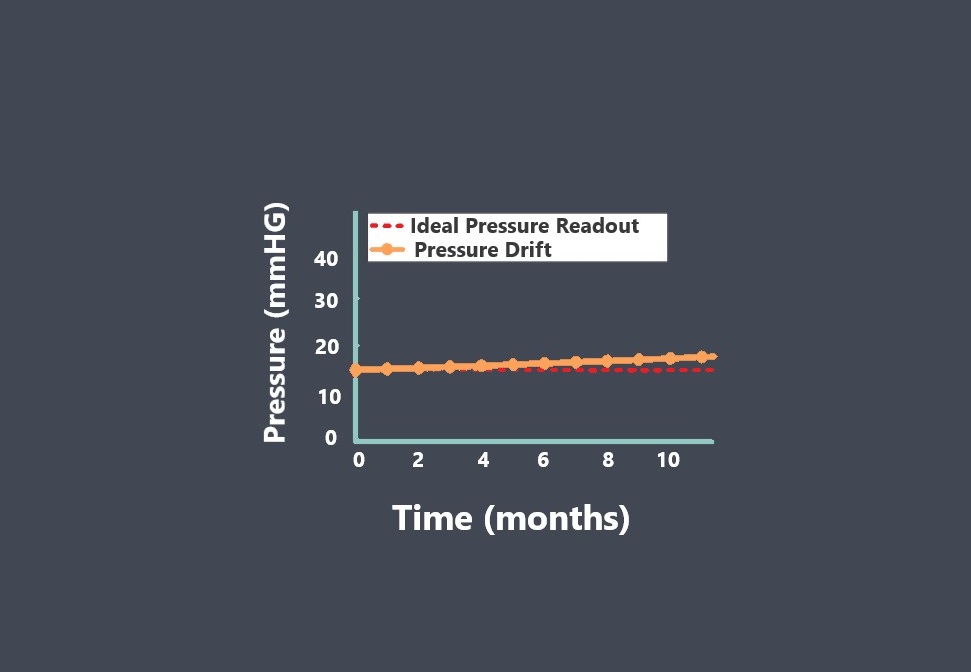

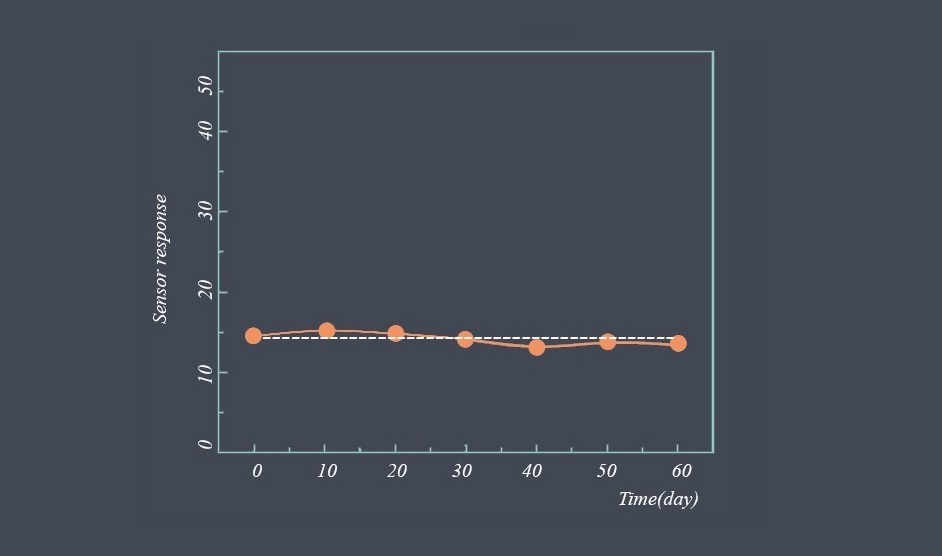

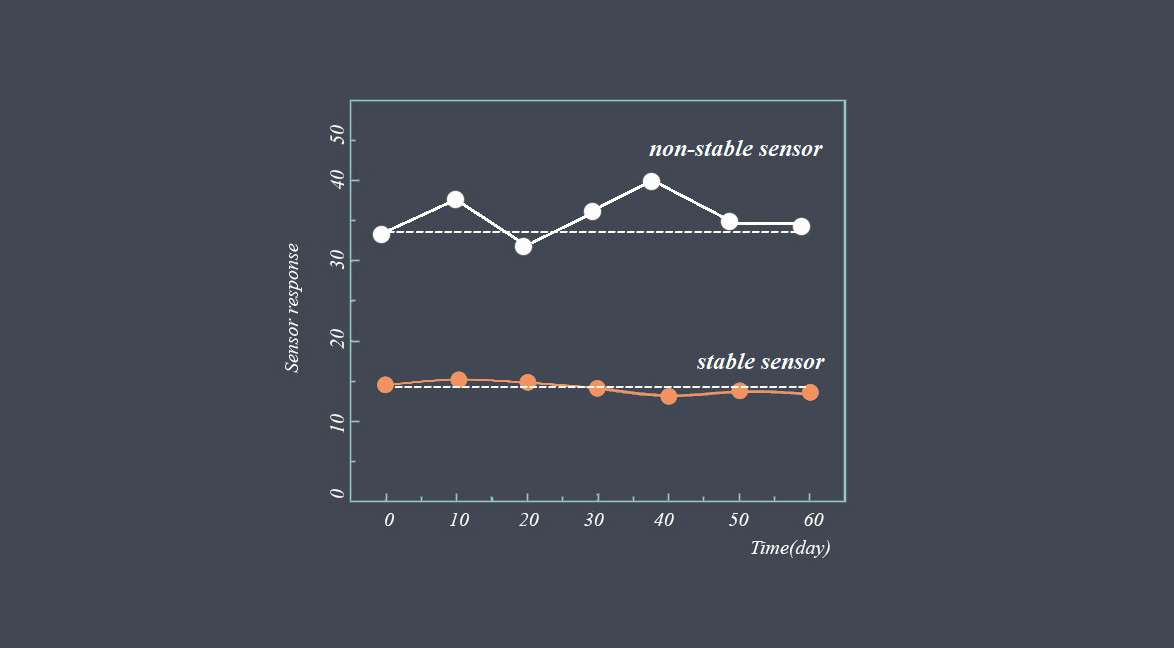

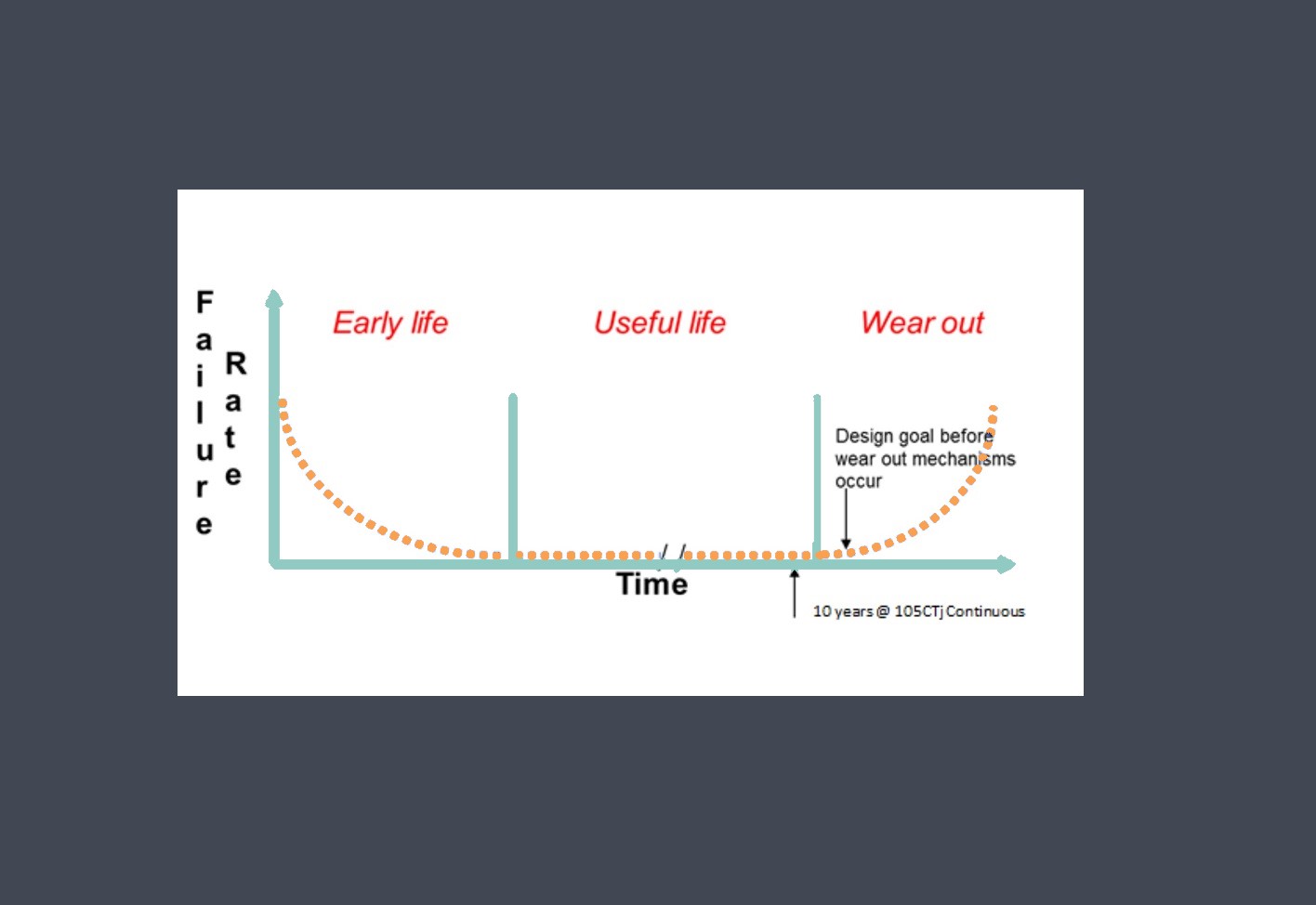

Sensor offset can change over time due to aging, environmental conditions, or other factors. It’s crucial to periodically assess and account for any changes in offset to maintain the reliability of sensor measurements. Failing to address offset drift can result in incorrect data interpretation or malfunctioning systems.

Consistency

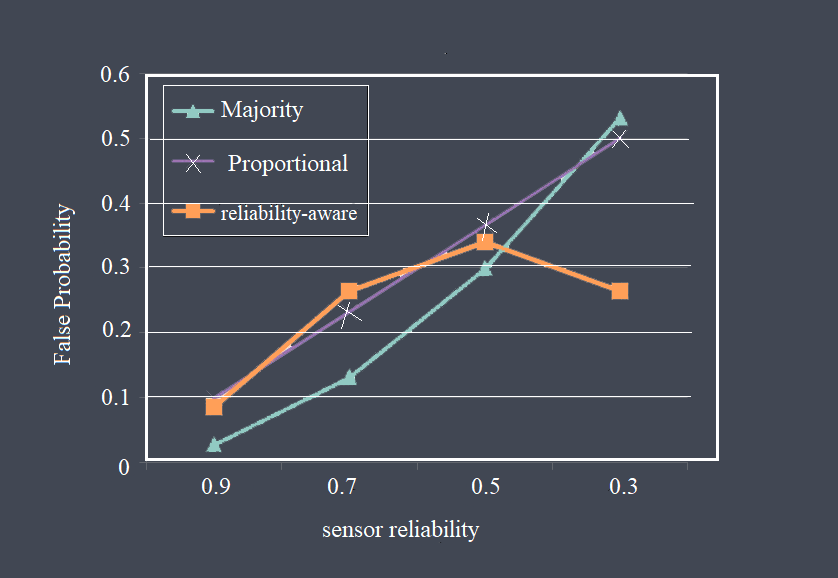

In applications where multiple sensors are used to gather data, having consistent measurements is essential for reliable data analysis and comparison. By compensating for sensor offset, the readings from different sensors can be aligned and synchronized, ensuring consistency across the system.

Understanding the offset of a sensor is crucial for obtaining accurate and reliable measurements. By applying appropriate calibration techniques and compensating for the offset, users can ensure the sensor’s output aligns with the true zero input value and minimize errors in their measurements.

Types of sensor offset

Zero offset and span offset are two specific types of sensor offsets that commonly occur in sensors. Let’s explore each of them:

- Zero Offset:

Zero offset, also known as zero error or zero drift, refers to the deviation of a sensor’s output from zero when there is no input stimulus. In other words, it is the discrepancy between the sensor’s output reading at zero input and the expected value of zero. A zero offset

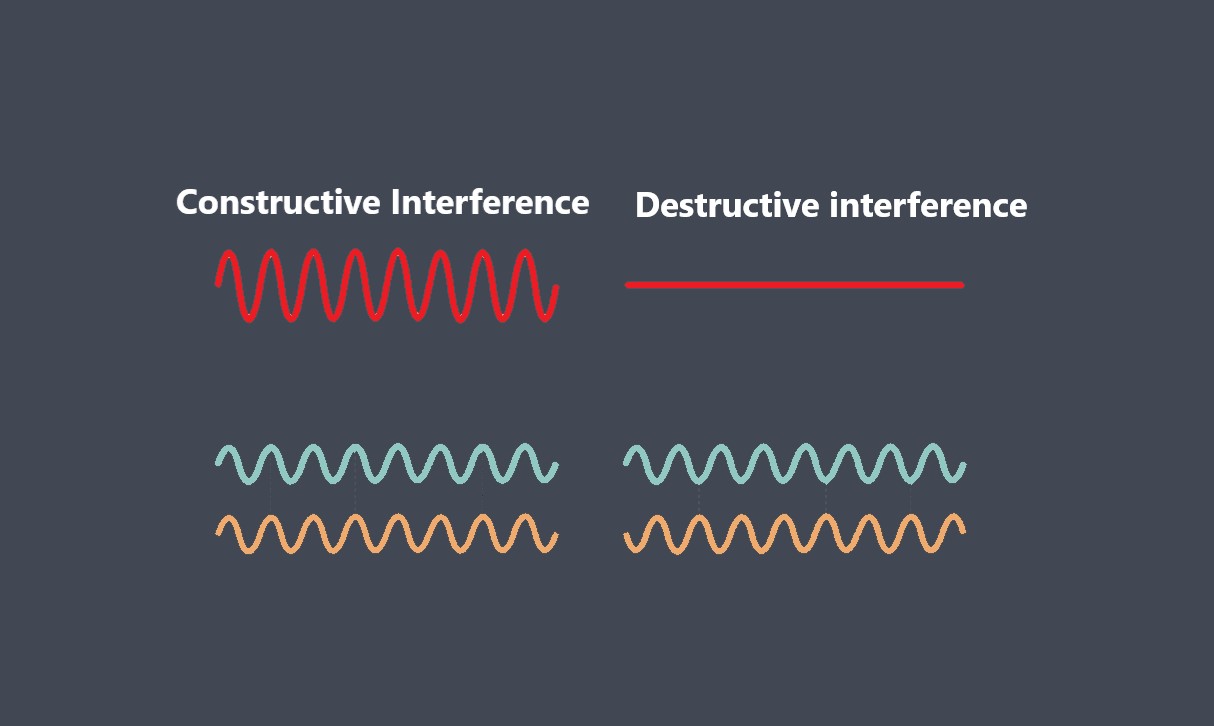

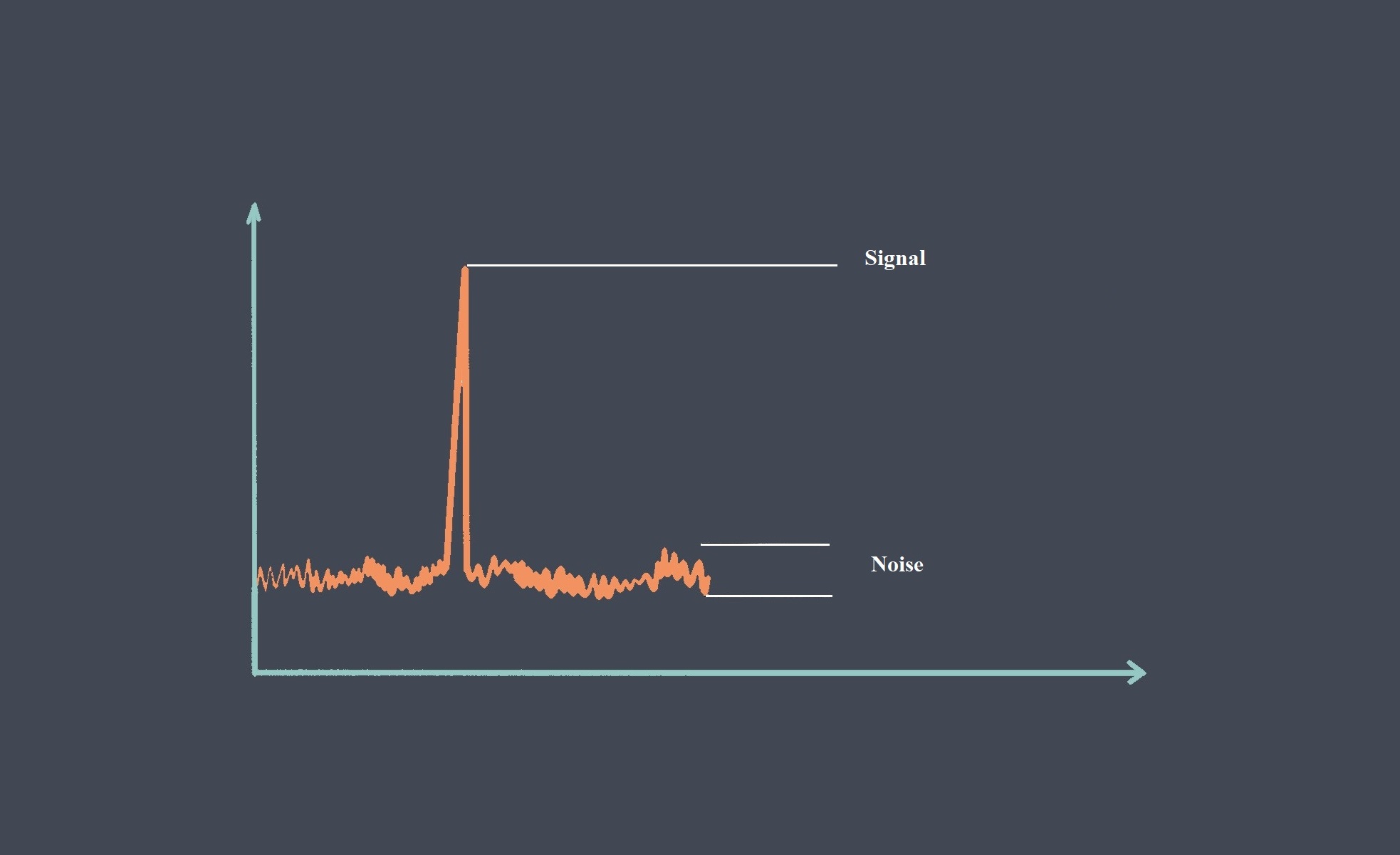

can be caused by factors such as electrical noise, manufacturing imperfections, or changes in the sensor’s characteristics over time. It is typically expressed as an additive value that needs to be taken into account when interpreting the sensor’s measurements.

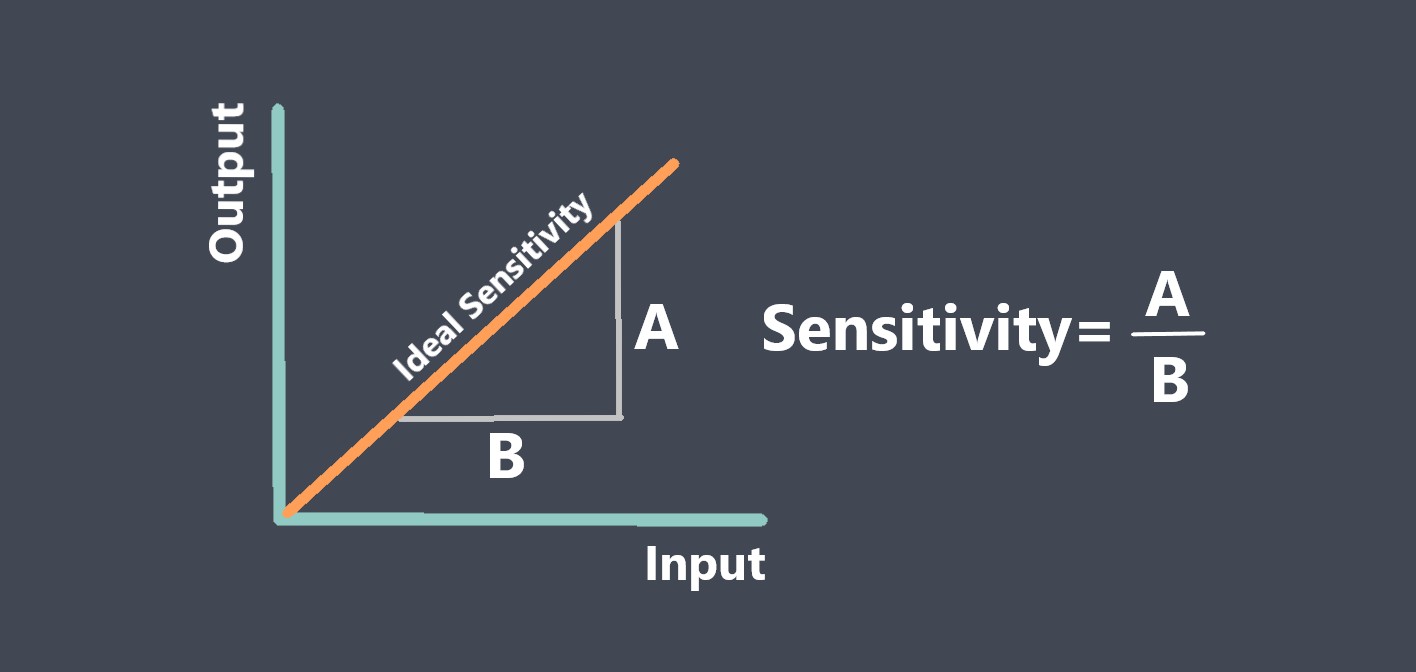

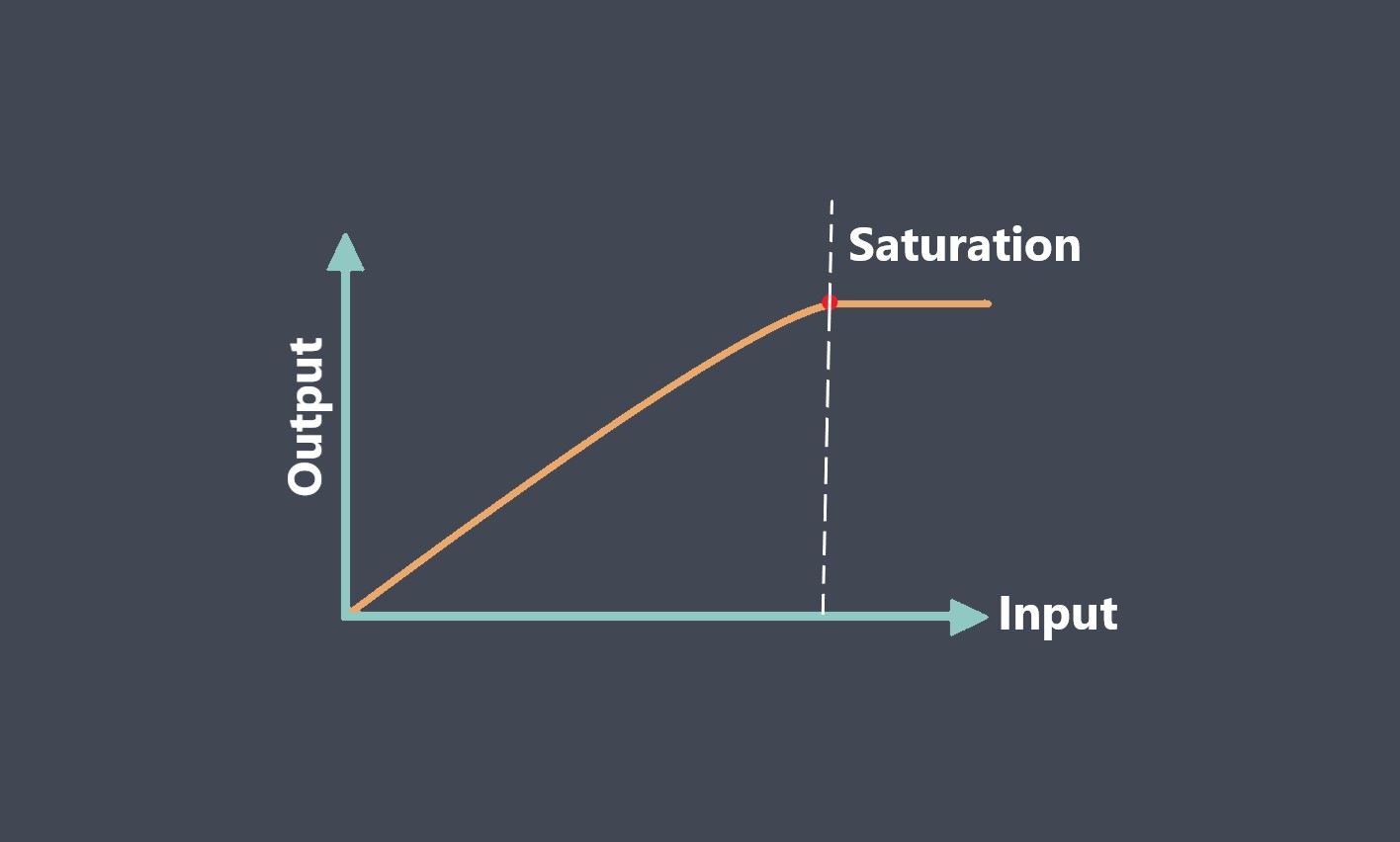

2. Span Offset:

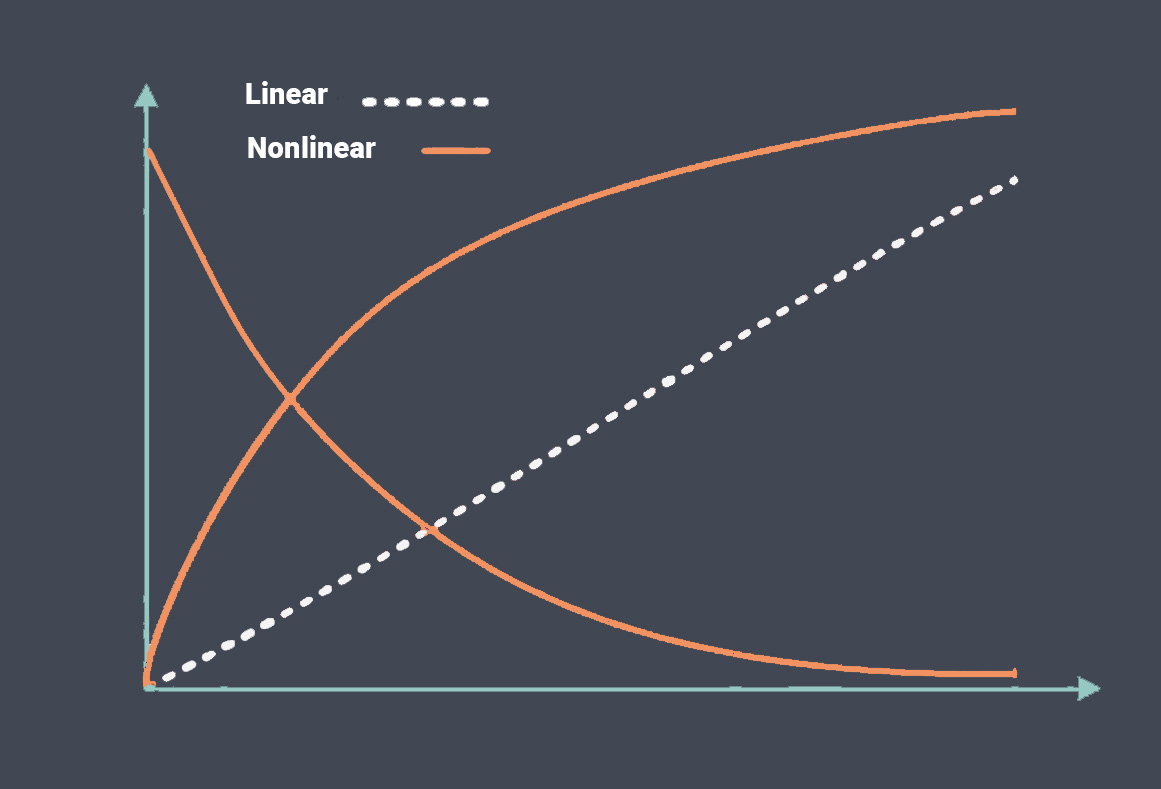

Span offset, also called gain offset or sensitivity offset, represents the variation in the sensor’s sensitivity or gain factor. It causes the sensor’s output to deviate from the expected value based on the magnitude of the input stimulus. Unlike zero offset, which affects the baseline or starting point of the sensor’s output,

span offset affects the scaling or amplification of the sensor’s output. A span offset can arise due to factors such as calibration errors, variations in component properties, or changes in environmental conditions. Span offset is often represented as a multiplicative factor that needs to be applied to the raw sensor readings to obtain accurate measurements.

To ensure accurate measurements, both zero offset and span offset need to be considered during sensor calibration and compensation processes. Calibration techniques can be employed to determine the actual offsets and then apply corrections to the sensor’s output to minimize the impact of these offsets on the measurements.

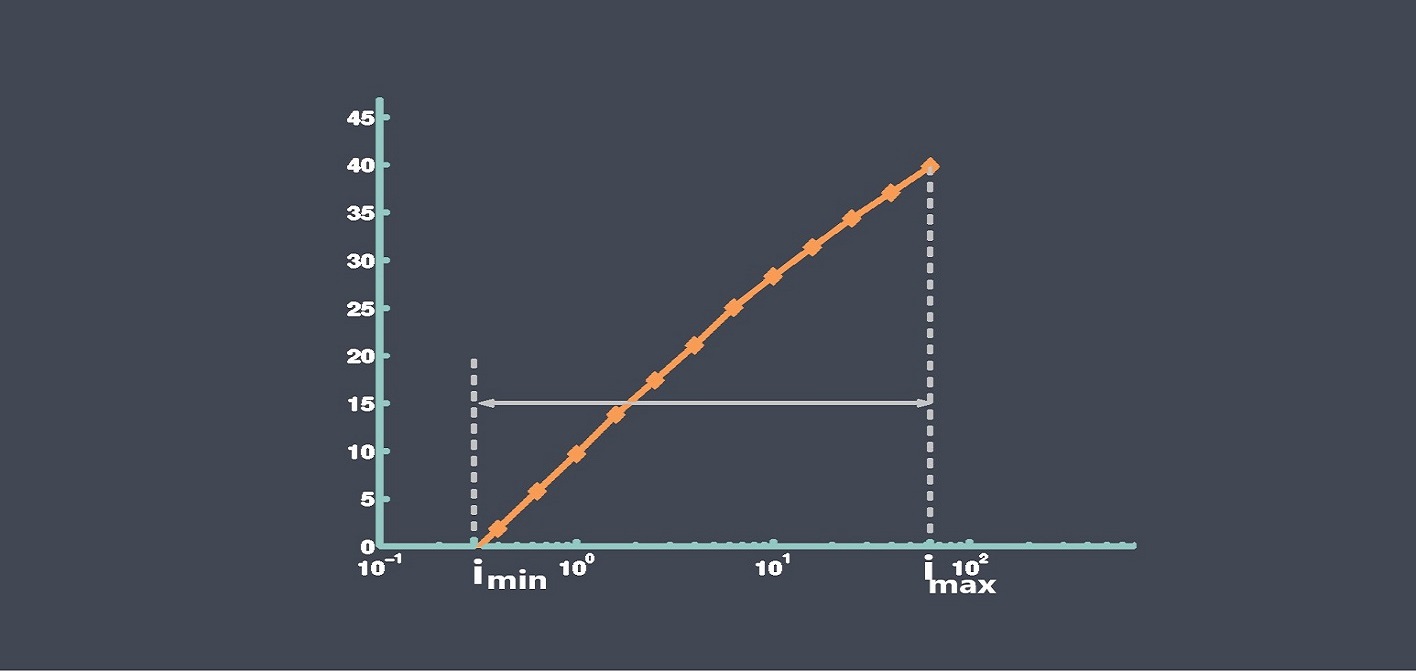

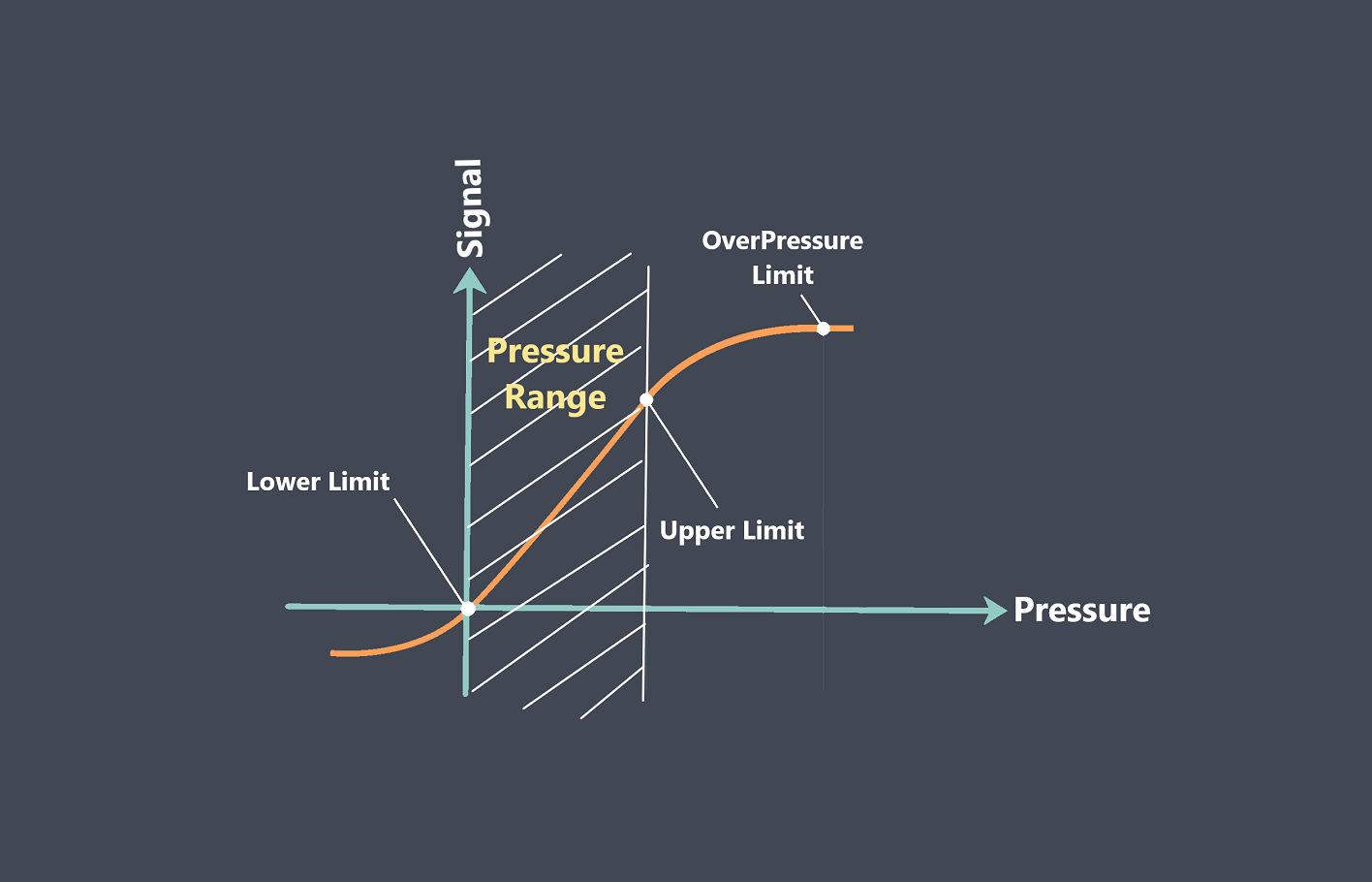

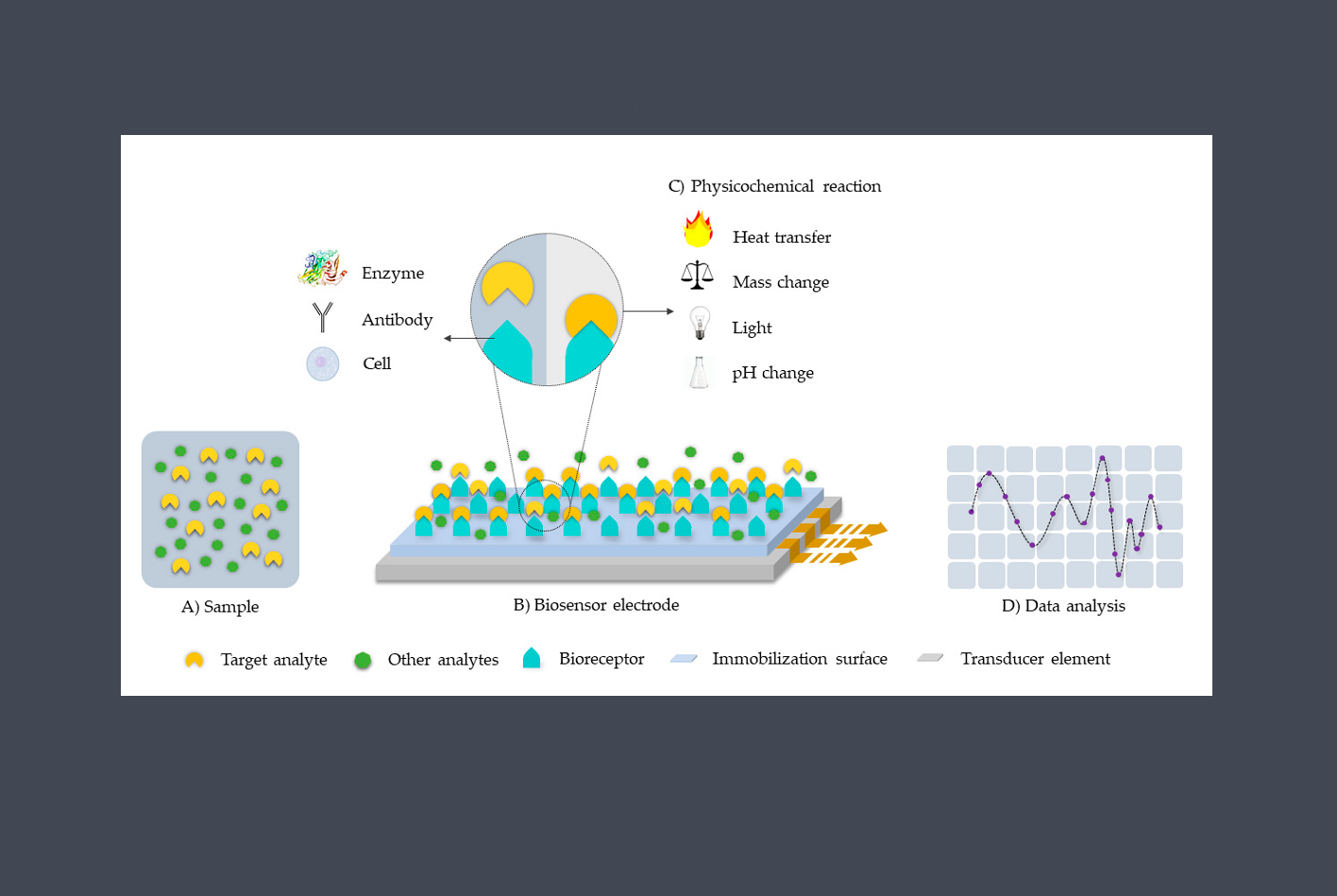

Various factors that cause offset

Offset can be caused by various factors, including manufacturing tolerances, electronic circuitry, or environmental conditions. It is crucial to understand and account for the offset to ensure accurate measurements, especially when the input signal is near or at the lower end of the sensor’s measurement range.

Some of the factors that can cause sensor offset are listed below:

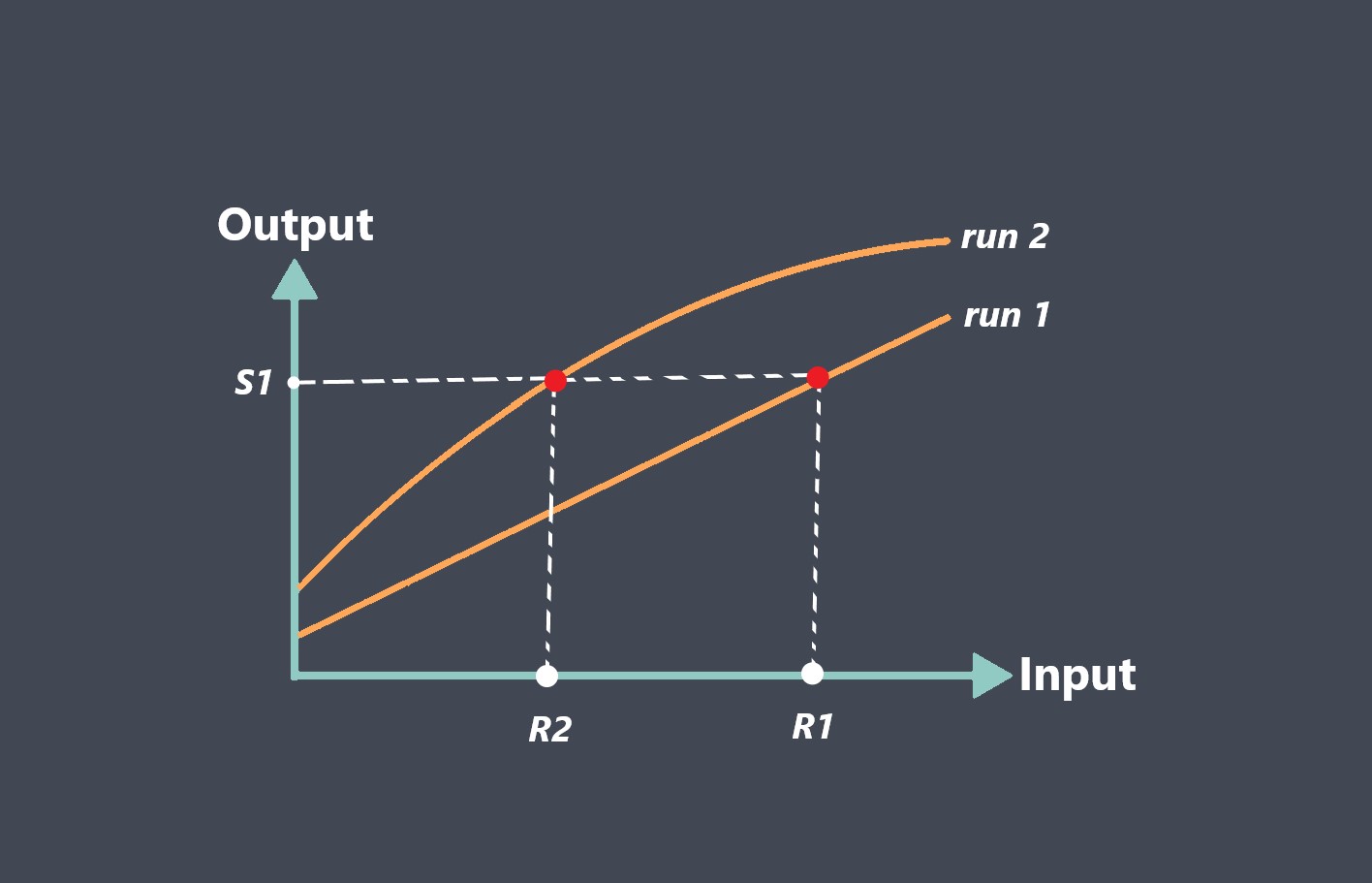

Calibration drift

Over time, sensors may experience changes in their calibration due to aging, environmental conditions, or other factors. This can lead to an offset in the measurements.

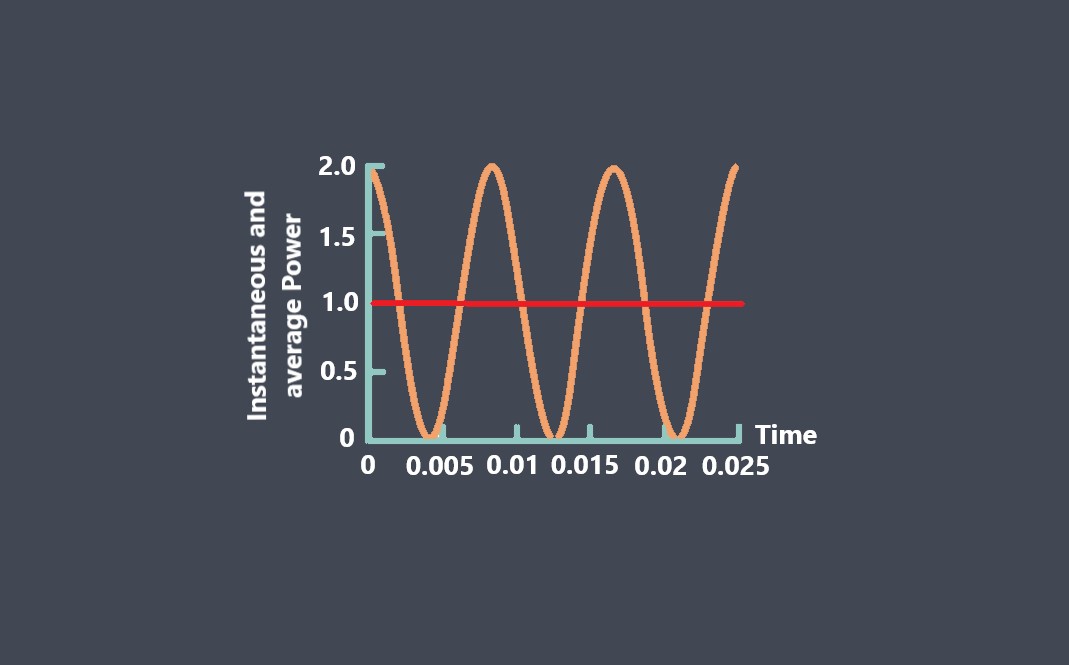

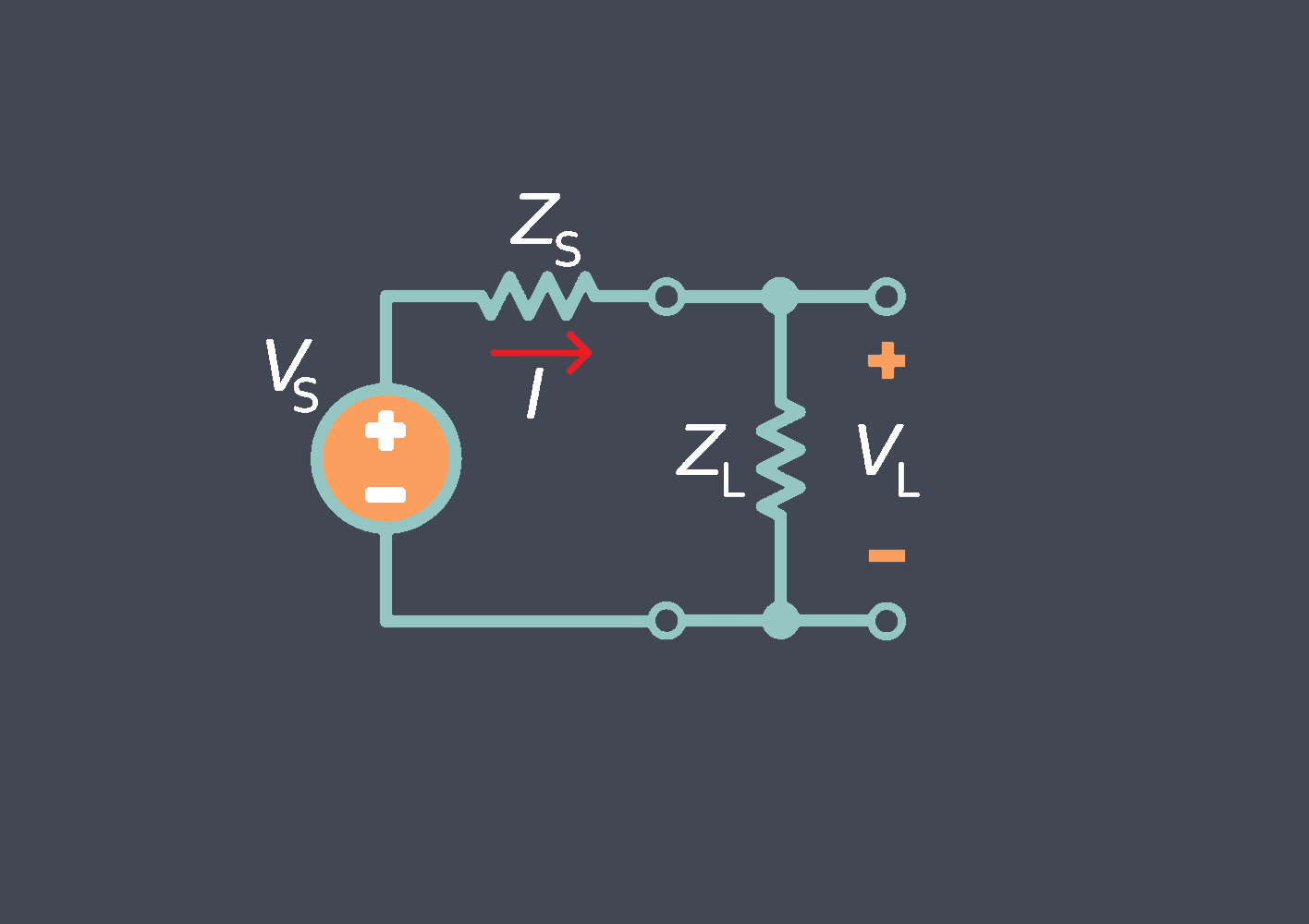

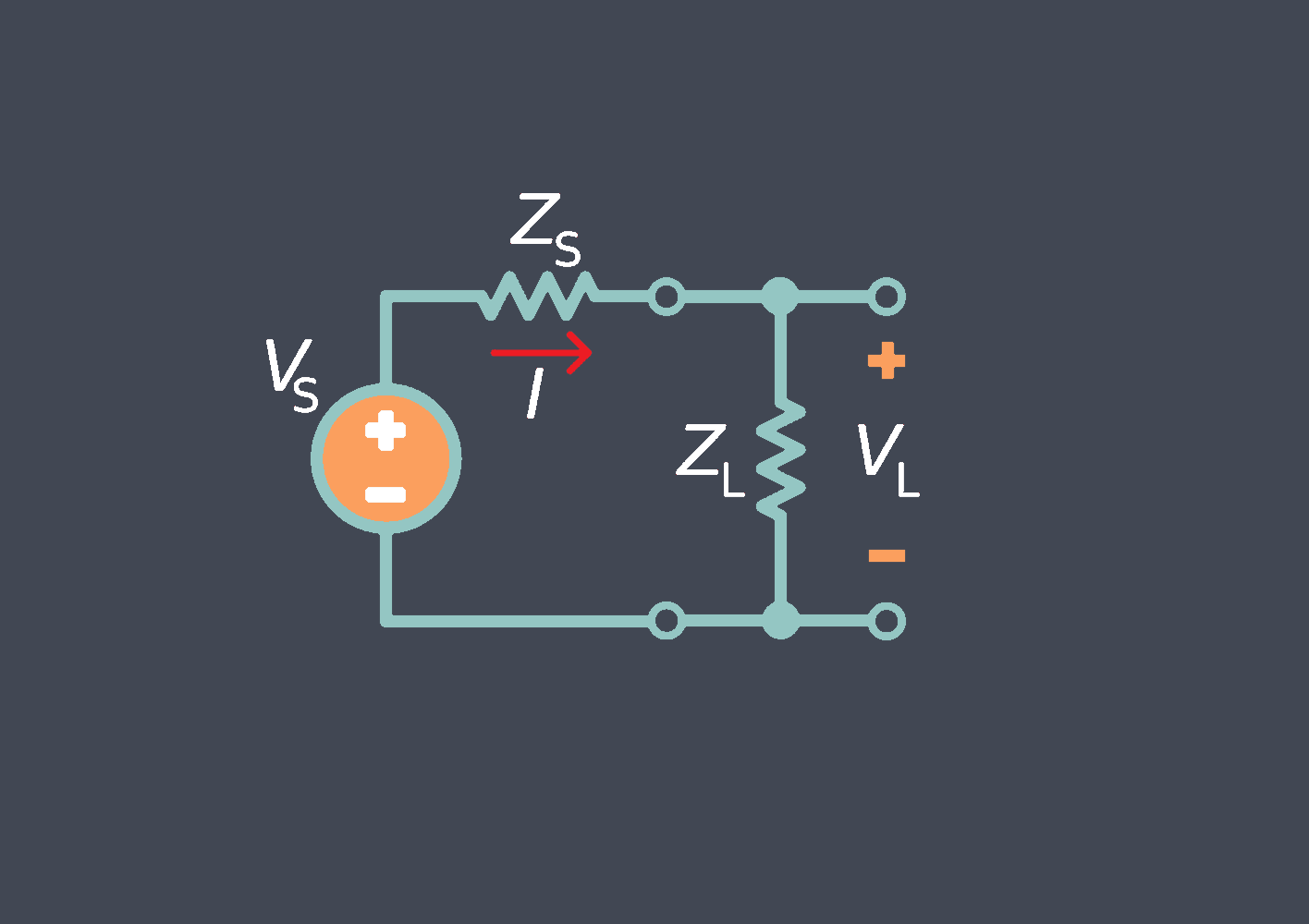

Inadequate power supply or voltage fluctuations can affect the performance of sensors, leading to offset errors in measurements.

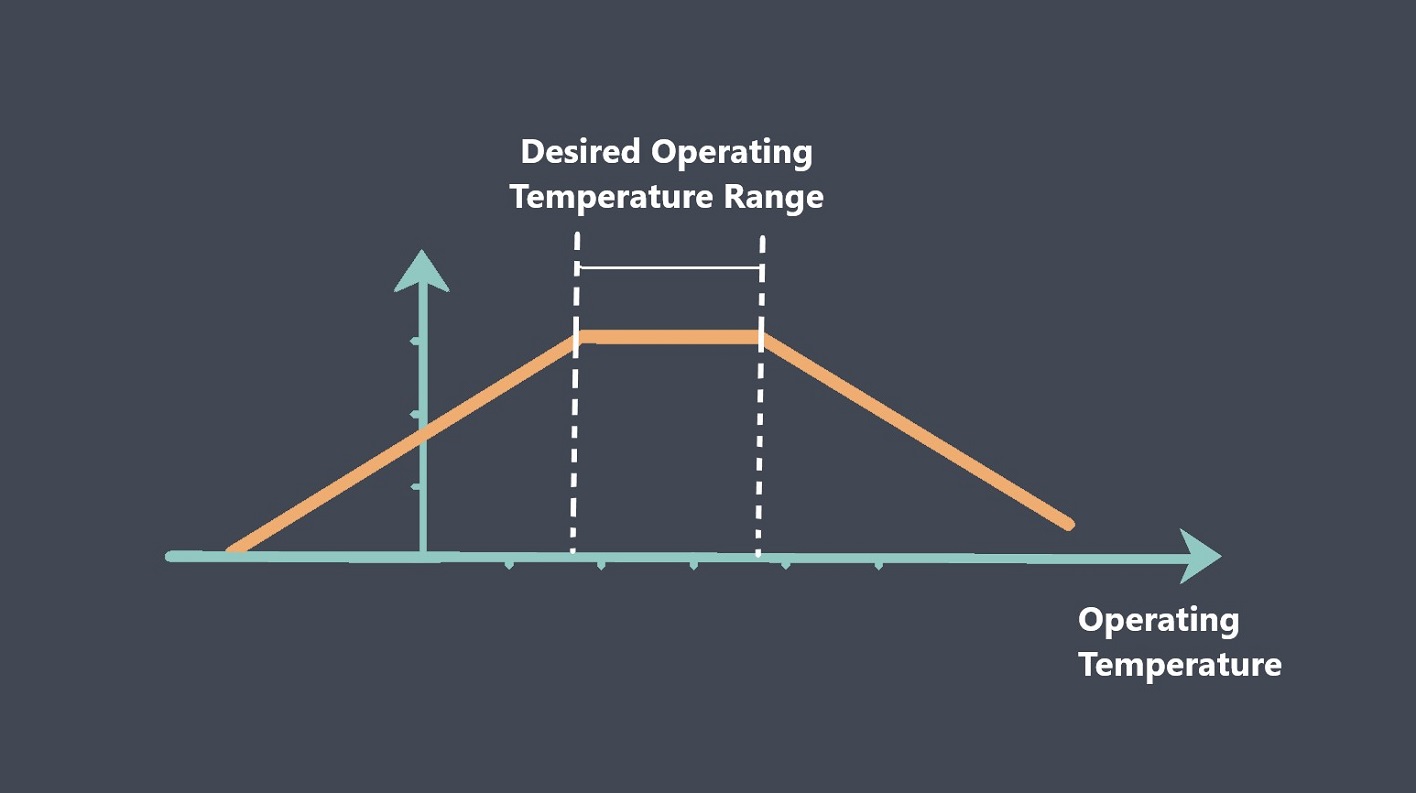

Temperature effects

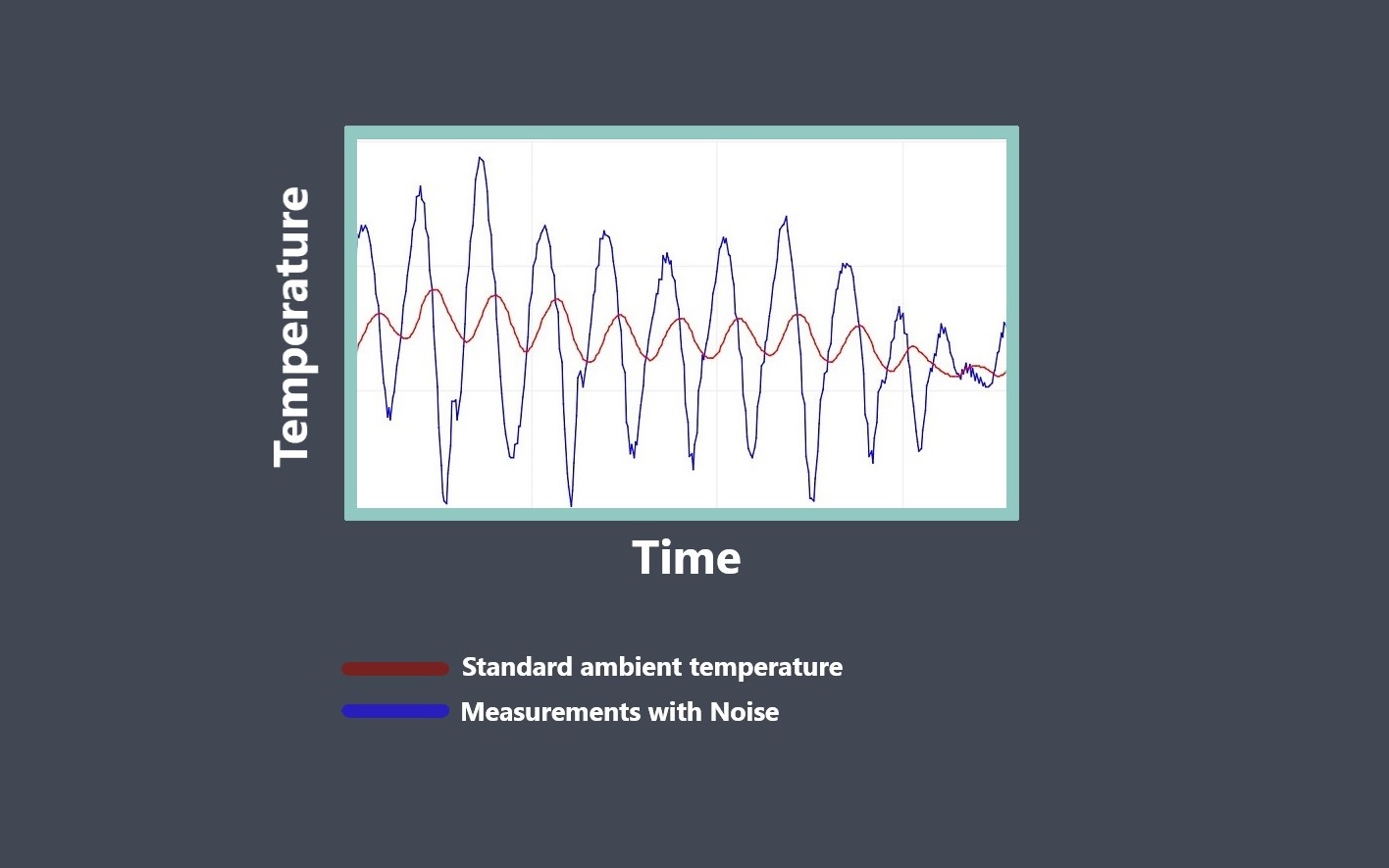

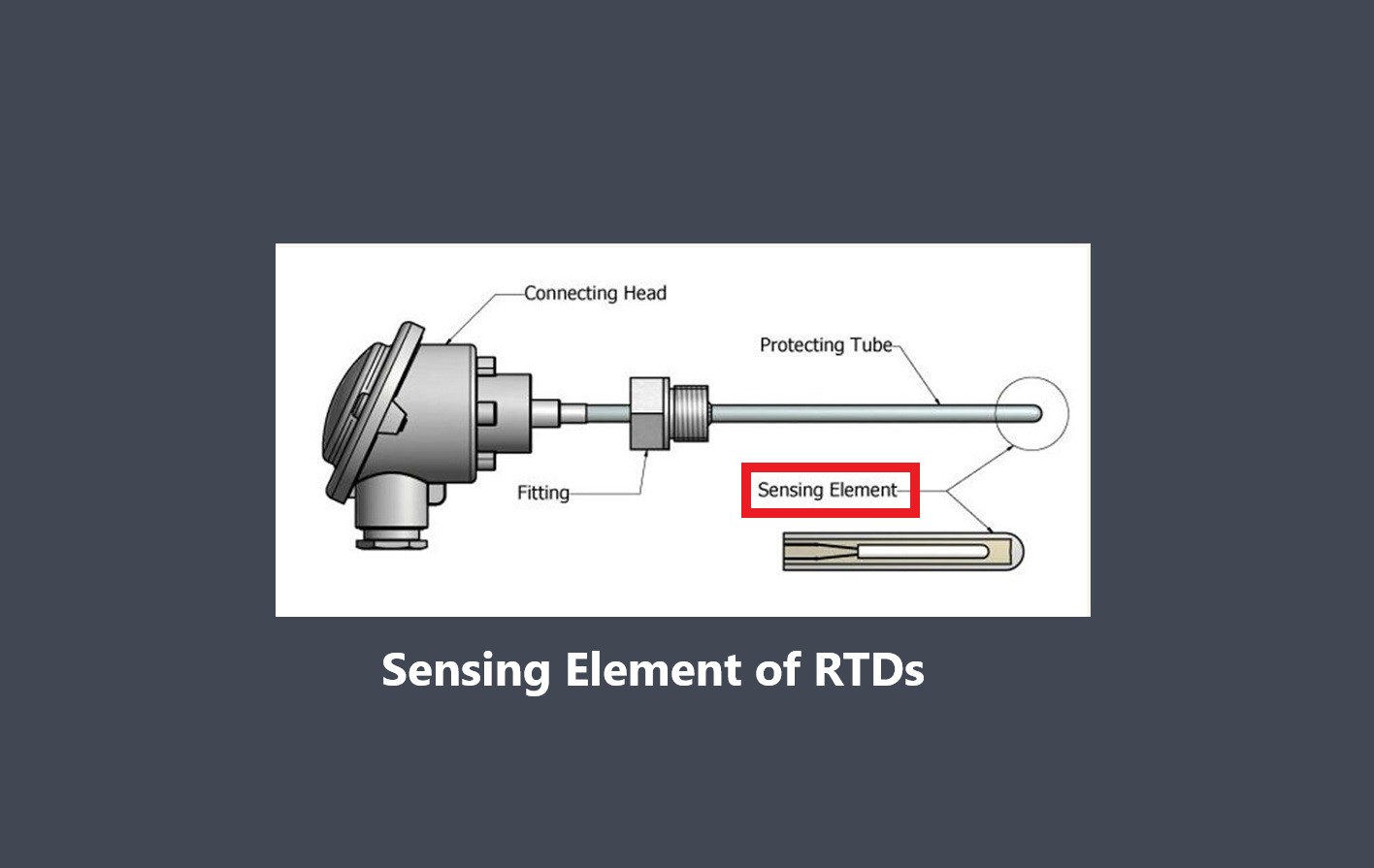

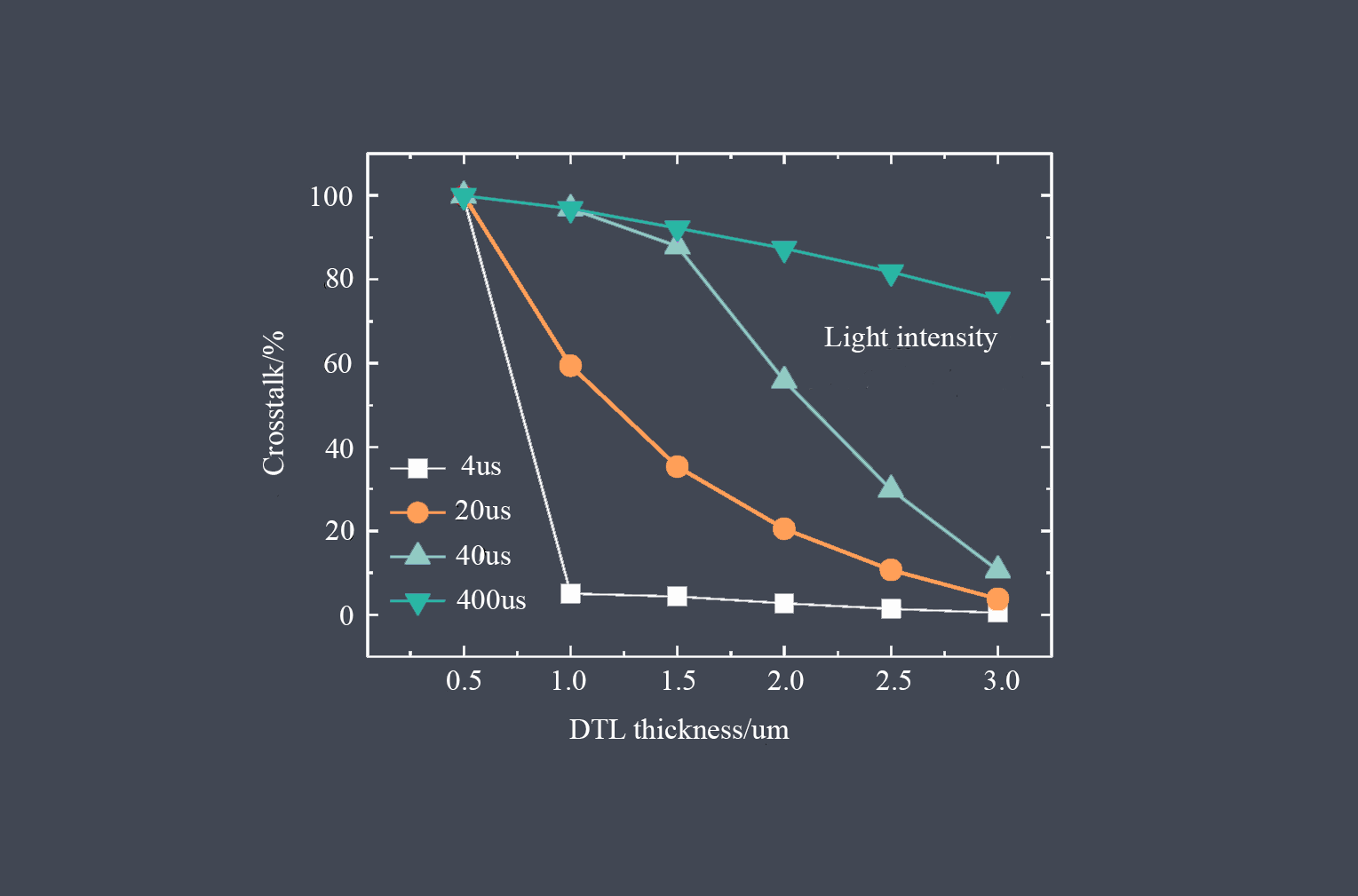

Changes in temperature can affect the behavior of sensors, especially those that rely on physical properties like resistance or capacitance. Temperature variations can introduce offsets in the sensor readings.

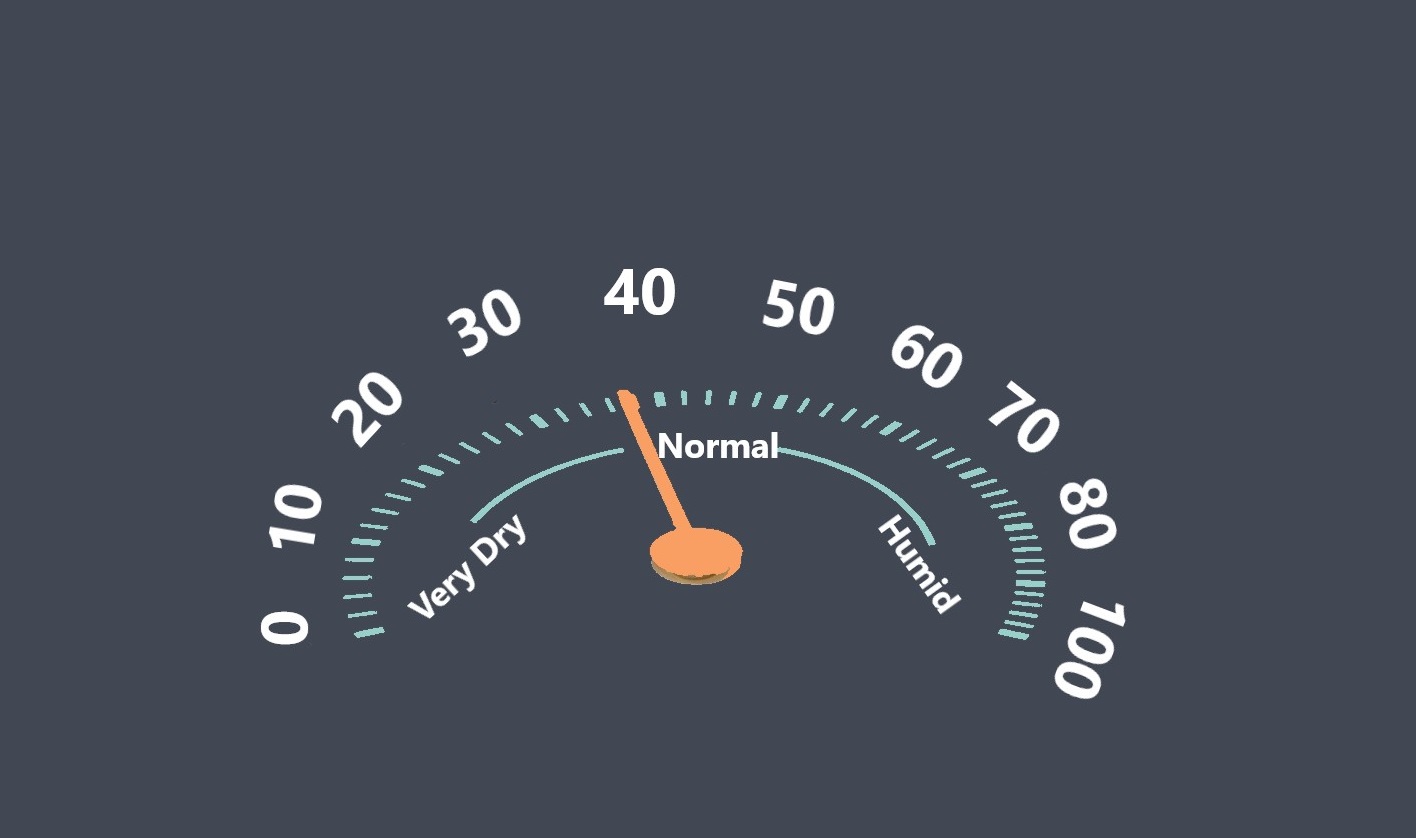

Environmental conditions

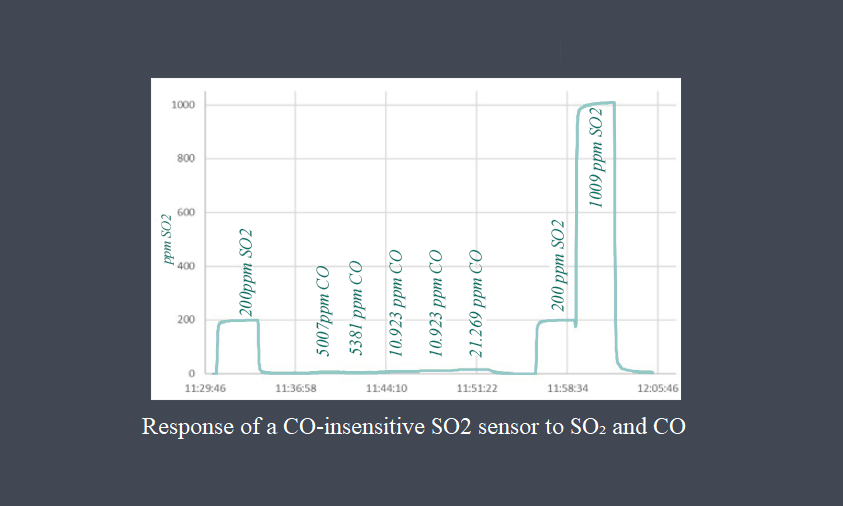

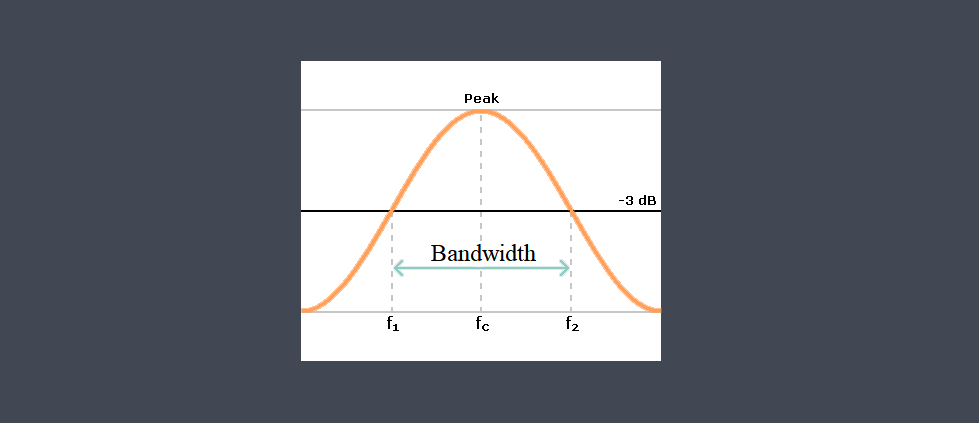

Factors such as humidity, pressure, electromagnetic interference, or ambient noise can impact sensor accuracy and introduce offsets.

Mechanical stress

Sensors can undergo mechanical stress or strain, which can alter their sensitivity or introduce shifts in their output readings.

Manufacturing tolerances

Variations in the manufacturing process can lead to slight differences in sensor characteristics, resulting in offset errors among sensors of the same type.

Power supply fluctuations

Inadequate power supply or voltage fluctuations can affect the performance of sensors, leading to offset errors in measurements.

Signal conditioning circuitry

Errors in the design or implementation of signal conditioning circuits can introduce offsets in the sensor output.

How to compensate the sensor offset?

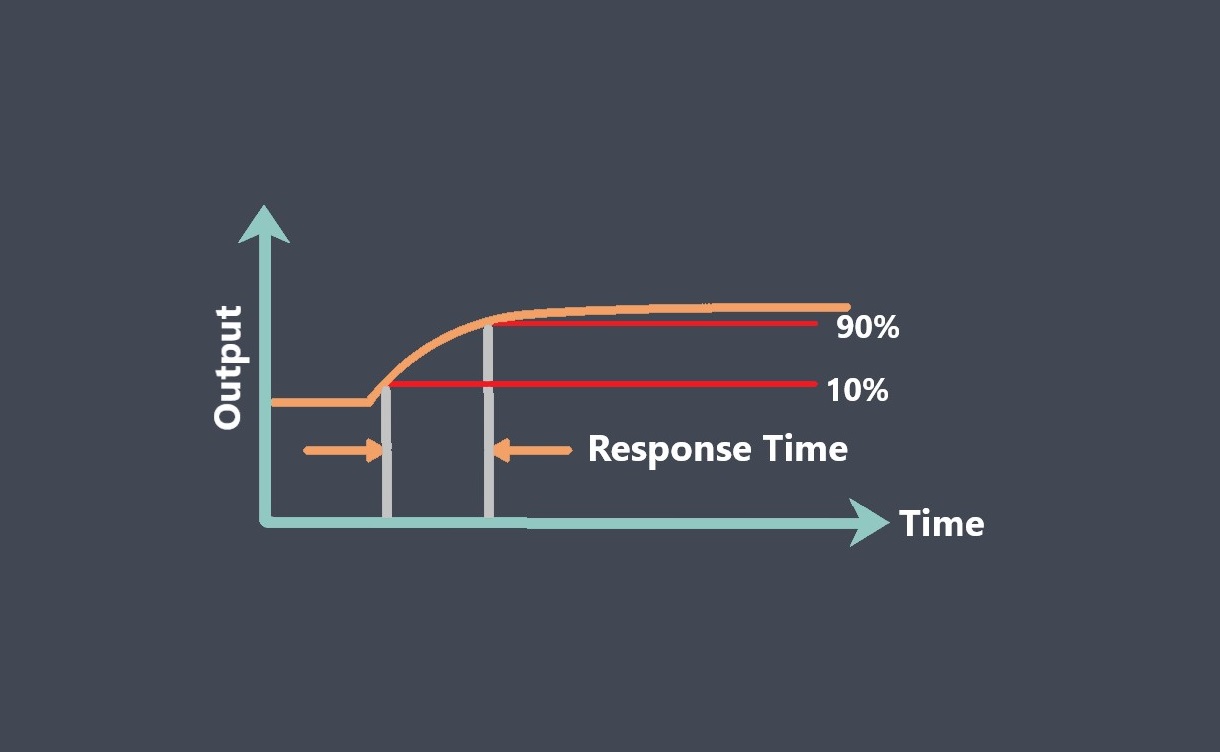

To compensate for offset, calibration techniques are commonly employed. Calibration involves determining the offset value and adjusting the sensor’s output signal accordingly. This can be done by measuring the sensor’s output at zero input and establishing a reference point or by employing specific calibration procedures recommended by the sensor manufacturer.

By compensating for offset, the sensor’s output can be effectively shifted to align with the true zero value, minimizing measurement errors. Accurate offset compensation ensures that the sensor provides reliable and precise measurements throughout its operating range, enhancing the overall performance and accuracy of the sensor.

It’s important to note that offset can be influenced by external factors such as temperature, humidity, or aging effects. Therefore, periodic recalibration and monitoring of the sensor’s offset are necessary to maintain accurate measurements over time.

Understanding the offset of a sensor is crucial for obtaining accurate and reliable measurements. By applying appropriate calibration techniques and compensating for the offset, users can ensure the sensor’s output aligns with the true zero input value and minimize errors in their measurements.