A gyroscope measures angular velocity or rotation rate around an axis. It is used to detect and measure the orientation or movement of an object. Types include mechanical gyroscopes, fiber optic gyroscopes, and MEMS gyroscopes. Applications include navigation systems, virtual reality devices, robotics, and motion tracking.

A gyroscope is a device that is used to measure or maintain orientation and angular velocity. It works based on the principle of conservation of angular momentum.

A gyroscope typically consists of a spinning rotor and a set of gimbals or pivoted supports. The spinning rotor in gyroscope provides angular momentum.

Gyroscopes basic working principle

The basic concept behind a gyroscope is the spinning rotor or wheel. When the rotor spins, it creates angular momentum, which is the tendency of an object to keep rotating in the same direction unless acted upon by an external force. This means that the axis of rotation of the rotor remains fixed in space.

When external forces are applied to the gyroscope, such as tilting or rotating the device, the gyroscopic effect comes into play. The angular momentum of the spinning rotor resists any changes in orientation. This causes the gyroscope to exhibit precession, which is the phenomenon of the axis of rotation gradually changing direction in response to external forces.

Gyroscopes types based on the number of their axes

Based on their axes, gyroscopes can be categorized into the following types:

Single-Axis Gyroscope

Also known as a one-axis gyroscope, this type measures rotation around a single axis. It provides angular rate information about the roll, pitch, or yaw of an object. Single-axis gyroscopes are commonly used in applications such as stabilizing cameras, navigation systems, and drones.

Dual-Axis Gyroscope

A dual-axis gyroscope measures rotation around two perpendicular axes. It provides angular rate information about

two specific directions simultaneously. This type of gyroscope is often used in applications that require more precise motion sensing, such as gaming controllers, virtual reality devices, and image stabilization systems.

Three-Axis Gyroscope

A three-axis gyroscope measures rotation around all three axes: X, Y, and Z. It provides angular rate information about roll, pitch, and yaw simultaneously. Three-axis gyroscopes are widely used in various applications, including smartphones, drones, robotics, and aerospace systems.

It’s worth noting that many modern gyroscopes integrate multiple axes into a single sensor package, providing three-axis or multi-axis measurements in a compact form factor. These gyroscopes often incorporate additional sensors, such as accelerometers, to provide a complete motion sensing solution.

The choice of gyroscope type depends on the specific application requirements, such as the desired level of accuracy, complexity, power consumption, and cost considerations.

Gyroscopes types based on their technology

There are different types of gyroscope sensors available, Here we are going to know them:

MEMS Gyroscopes

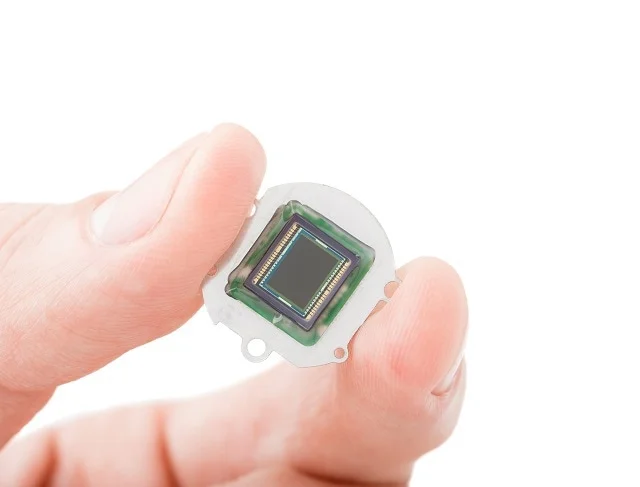

MEMS (Microelectromechanical Systems) gyroscopes are a type of gyroscope that utilizes microfabrication technology to create miniature sensors. These gyroscopes are built on a silicon wafer using integrated circuit manufacturing techniques, allowing them to be highly compact, lightweight, and cost-effective.

MEMS gyroscopes typically employ a vibrating mass or a resonating structure, known as an oscillating proof mass, which experiences a Coriolis force when the gyroscope undergoes rotation. This force causes the proof mass to deflect, and the resulting deflection is measured to determine the angular velocity or rate of rotation.

MEMS gyroscopes advantages/disadvantages and applications:

MEMS gyroscopes have become widely used in various applications due to their small size, low power consumption, and compatibility with integrated circuit technology. They find applications in smartphones for motion sensing and image stabilization, gaming controllers, virtual reality devices, drones, robotics, navigation systems, and many other electronic devices requiring motion detection and measurement.

It’s important to note that while MEMS gyroscopes offer advantages in terms of miniaturization and cost, they may have limitations compared to larger and more precise gyroscopes, such as lower accuracy, sensitivity to environmental conditions, and potential drift over time. However, continuous advancements in MEMS technology have led to significant improvements in their performance and reliability.

Fiber Optic Gyroscopes (FOG)

Fiber Optic Gyroscopes (FOGs) are another type of gyroscope that use the principles of fiber optics to measure angular velocity or rotation. Instead of relying on a moving mechanical part like in MEMS gyroscopes, FOGs utilize the interference of light to detect rotations.

In a FOG, a laser beam is split into two paths: the clockwise (CW) and counterclockwise (CCW) paths. These paths are guided through a coil of optical fiber wound in a coil pattern, which is typically several meters long. The fiber coil acts as the sensing element of the gyroscope.

As the gyroscope undergoes rotation, a phenomenon known as the Sagnac effect occurs. This effect causes a phase shift between the CW and CCW light beams due to the difference in the distances traveled by each beam. When the beams are recombined, an interference pattern is formed. By measuring this interference pattern, the FOG can determine the rotation rate.

Fiber Optic Gyroscopes (FOGs) advantages/disadvantages and applications:

One of the advantages of FOGs is their high accuracy and stability. They are capable of detecting extremely small angular velocities and have excellent long-term stability. FOGs also offer a wide dynamic range, meaning they can measure both slow and fast rotational motions.

FOGs are commonly used in a variety of applications where precise rotation sensing is required. They are used in navigation systems for aircraft, ships, and submarines, as well as in inertial measurement units (IMUs) for autonomous vehicles and aerospace applications. FOGs are also utilized in robotics, industrial equipment, and even in some consumer electronic devices.

FOGs tend to be larger and more expensive than MEMS gyroscopes. However, they offer higher performance in terms of accuracy and stability, making them suitable for critical applications where precise rotational information is needed.

Ring Laser Gyroscopes (RLG)

Ring Laser Gyroscopes (RLGs) are another type of gyroscope used to measure angular velocity or rotation. RLGs operate on the same principle as FOGs, but instead of using a coiled optical fiber, they use a ring-shaped cavity formed by mirrors and lasers.

In an RLG, two laser beams travel in opposite directions around the closed loop formed by the cavity. As the gyroscope rotates, the difference in the distances traveled by the beams causes a phase difference. This phase difference is detected when the beams recombine, resulting in an interference pattern.

By analyzing the interference pattern, the RLG can determine the rotation rate. The detection of the phase shift is accomplished using photodetectors, which convert the light signals into electrical signals that can be measured and processed.

Ring Laser Gyroscopes (RLG) advantages/disadvantages and applications:

One of the advantages of RLGs is their ability to provide accurate and precise rotation measurements. They have excellent resolution and stability, making them suitable for applications that require high precision, such as navigation systems for aircraft and spacecraft.

RLGs are commonly used in aviation, aerospace, and defense industries. They are utilized in inertial navigation systems, attitude and heading reference systems (AHRS), and gyrocompasses. RLGs are also employed in various scientific and research applications where accurate rotation sensing is essential.

Compared to FOGs, RLGs tend to be more compact and lightweight, making them suitable for applications where space is limited. However, RLGs can be more expensive than FOGs due to the complexity of their design and manufacturing process.

Both FOGs and RLGs are well-established technologies and have their own strengths depending on the specific requirements of an application.

Piezoelectric Gyroscopes

Piezoelectric gyroscopes are a type of gyroscope that utilize the piezoelectric effect to measure angular velocity or rotation. The piezoelectric effect is the ability of certain materials to generate an electric charge when subjected to mechanical stress, and conversely, to deform when an electric field is applied to them.

In a piezoelectric gyroscope, a vibrating mass or resonator is used to sense the rotation. This mass is usually made of a piezoelectric material such as quartz, which exhibits the piezoelectric effect. When the gyroscope rotates, the Coriolis effect causes the mass to experience a force perpendicular to its motion, leading to its deformation.

The deformation of the piezoelectric mass generates an electrical signal, which is then measured and analyzed to determine the rate of rotation. This is accomplished by sensing changes in the electrical characteristics, such as voltage or frequency, produced by the piezoelectric effect.

Piezoelectric Gyroscopes advantages/disadvantages and applications:

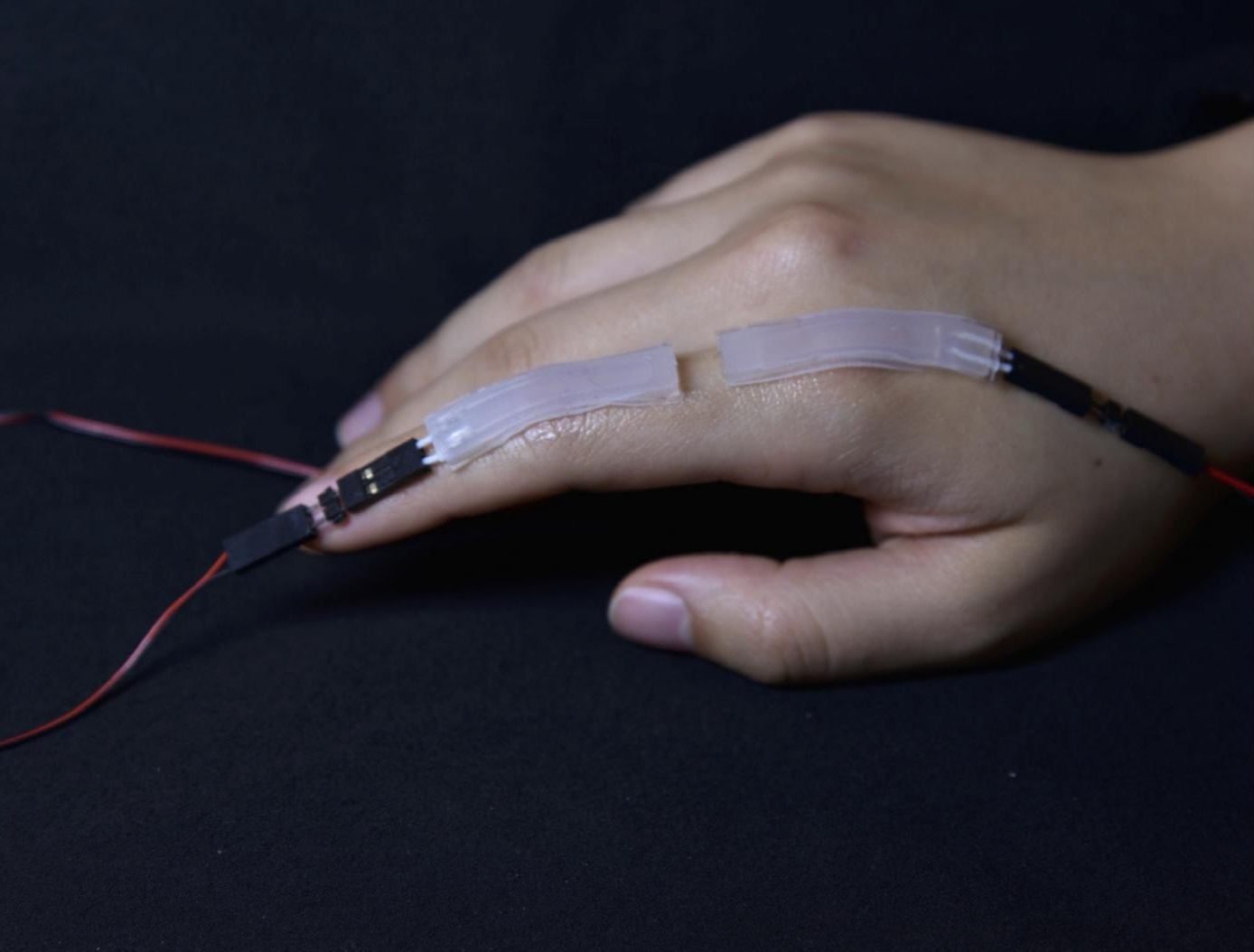

One of the advantages of piezoelectric gyroscopes is their small size and low power consumption. They can be manufactured in compact packages, making them suitable for applications where size and weight are critical considerations, such as in consumer electronics like smartphones, wearables, and game controllers.

However, piezoelectric gyroscopes typically have lower accuracy and stability compared to other types of gyroscopes, such as fiber optic gyroscopes (FOGs) or ring laser gyroscopes (RLGs). They are often used in applications that require relatively modest levels of precision, such as navigation in consumer devices or stabilization systems in cameras.

while piezoelectric gyroscopes have their limitations, ongoing advancements in technology continue to improve their performance, making them increasingly viable for a wider range of applications.

Fluid Gyroscopes

Fluid gyroscopes, also known as mechanical gyroscopes or spinning mass gyroscopes, are devices that utilize the properties of a rotating fluid to measure angular velocity or rotation. They have been used for various applications, including navigation systems, aerospace guidance, and even in consumer toys like spinning tops.

The principle behind fluid gyroscopes is based on the conservation of angular momentum. When a fluid-filled container is rotated around its axis, the fluid inside it also starts to rotate due to inertia. The rotating fluid creates a gyroscopic effect that resists changes in the orientation of the gyroscope.

Inside a fluid gyroscope, there is typically a spinning mass or rotor that contains the fluid. This rotor is supported by ball bearings or other means to reduce friction and allow for smooth rotation. As the gyroscope experiences angular rotation, the fluid inside resists any attempt to change its direction, enabling it to maintain stability with respect to an external reference frame.

The rate at which the rotor rotates can be sensed using various methods. One common approach is to use optical or magnetic sensors that detect changes in the position or velocity of the rotating mass. These changes are then converted into electrical signals that can be further processed and used to determine the angular velocity or rotation of the gyroscope.

Fluid Gyroscopes advantages/disadvantages and applications:

Fluid gyroscopes offer some advantages over other types of gyroscopes. They can provide robust and reliable measurements even in challenging environments, such as high vibration or extreme temperatures. Additionally, they can be relatively simple and cost-effective to manufacture compared to other gyroscopic technologies.

However, fluid gyroscopes also have limitations. They can be sensitive to external disturbances and may experience drift over time, requiring periodic calibration. Furthermore, their size and weight can be significant, limiting their use in certain applications where compactness is essential.

Despite these limitations, fluid gyroscopes continue to find applications in various industries. They are particularly useful in situations where ruggedness and simplicity are more important than extreme accuracy, such as in some industrial and automotive navigation systems.