An accelerometer measures acceleration or changes in velocity of an object. It is commonly used to detect motion, vibrations, and orientation changes. Types include piezoelectric, capacitive, and MEMS accelerometers. Applications include vehicle stability control, motion sensing in smartphones, robotics, and vibration monitoring.

An accelerometer is a device that measures acceleration, which is the rate of change in velocity of an object. It can detect and measure accelerations in any direction or axis.

Accelerometers work based on the principle of Newton’s second law of motion. They contain a mass (known as the proof mass) attached to a spring or a cantilever structure. The basic working principle of an accelerometer involves the use of a mass (known as the proof mass) that is suspended within the sensor. When subjected to acceleration, the proof mass experiences a force proportional to the acceleration, causing it to move. This displacement is then measured and converted into an electrical signal that can be interpreted by electronic circuits or systems.

Accelerometers can measure acceleration in one, two, or three axes depending on their configuration. Single-axis accelerometers measure acceleration along a single direction, while tri-axis accelerometers provide measurements in three perpendicular directions (X, Y, and Z axes).

Acceleration is typically measured in units of g-force, where 1 g is equal to the gravitational acceleration experienced on Earth’s surface (approximately 9.8 m/s²). The range of measurement varies depending on the specific accelerometer, but common ranges fall between ±1 g to ±16 g.

Accelerometers have a wide range of applications. In smartphones and gaming controllers, they enable screen orientation changes and motion-based interactions.

In automotive systems, they contribute to stability control and airbag deployment. In aerospace, accelerometers are essential for navigation, flight control, and vibration monitoring.

In many applications, multiple sensors such as accelerometers, gyroscopes, and magnetometers are combined using sensor fusion techniques to improve accuracy and provide more comprehensive motion sensing capabilities.

Accelerometer types based on their sensing methods

Accelerometers typically use one of several sensing methods to detect the movement of the proof mass. The most common sensing methods include piezoelectric, capacitive, and MEMS (Micro-Electro-Mechanical Systems). Here we are going to learn about each of them a little more.

Each method has its advantages and disadvantages, but they all aim to measure the displacement or change in capacitance caused by acceleration.

Piezoelectric accelerometer

A piezoelectric accelerometer is a type of accelerometer that utilizes the piezoelectric effect to measure acceleration. The piezoelectric effect refers to the ability of certain materials, such as certain crystals or ceramics, to generate an electric charge when subjected to mechanical stress or deformation.

In a piezoelectric accelerometer, the sensing element consists of a piezoelectric material, usually a crystal or ceramic wafer, that is bonded to a mass or proof mass. When the accelerometer experiences acceleration, the mass moves relative to the sensor body, causing the piezoelectric material to undergo mechanical deformation or stress.

As a result of this stress, the piezoelectric material generates an electric charge. This charge is then collected by electrodes located on the surface of the material. The magnitude of the charge is directly proportional to the applied acceleration.

To measure the generated charge, the accelerometer is connected to a charge amplifier or signal conditioning circuitry. The charge amplifier converts the small charge generated by the piezoelectric material into a measurable voltage signal.

The output signal from the piezoelectric accelerometer can be further processed and analyzed to determine various parameters, such as vibration amplitude, frequency, and direction of acceleration.

Piezoelectric accelerometers advantages and applications:

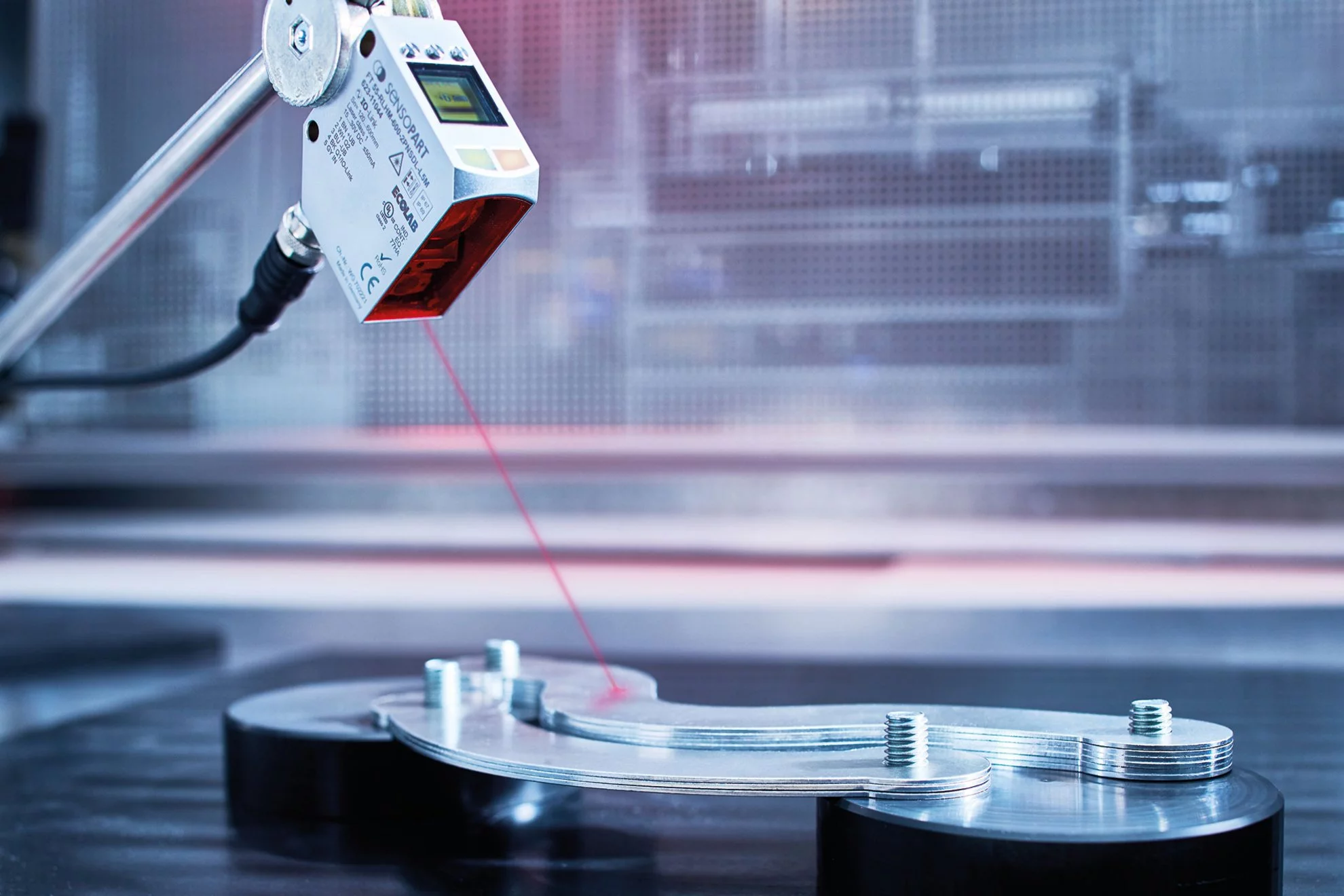

Piezoelectric accelerometers have several advantages, including high sensitivity, wide frequency response, and good linearity. They are commonly used in applications that require precise measurement of vibration, such as structural health monitoring, automotive testing, machinery diagnostics, and many other industrial and scientific applications.

Capacitive accelerometer

Capacitive accelerometers use changes in capacitance caused by the movement of the proof mass. The movement alters the gap between the proof mass and fixed capacitive plates, resulting in a change in capacitance, which is then converted into an electrical signal.

In a capacitive accelerometer, there are typically two sets of parallel plates: one fixed and one movable. The fixed plates are attached to the accelerometer frame or housing, while the movable plates are connected to a proof mass that moves in response to acceleration. When the accelerometer experiences linear or angular acceleration, the proof mass moves relative to the fixed plates, causing a change in the distance between the plates.

As the distance between the plates changes, the capacitance of the system also changes. This change in capacitance is directly proportional to the applied acceleration. The capacitive accelerometer measures this change in capacitance and converts it into an electrical output signal.

To accurately measure the capacitance change, capacitive accelerometers use various techniques. One common method is to use a bridge circuit, where the accelerometer is part of a balanced circuit with multiple capacitors. The output voltage of the bridge circuit is then proportional to the capacitance change.

Capacitive accelerometers advantages and applications:

Capacitive accelerometers have several advantages, including high accuracy, excellent linearity, and low noise. They are widely used in applications where precise measurement of acceleration is required, such as aerospace, automotive, and consumer electronics. Capacitive accelerometers are also suitable for measuring both static and dynamic acceleration, making them versatile for a range of applications.

MEMS (Micro-Electro-Mechanical Systems) accelerometer

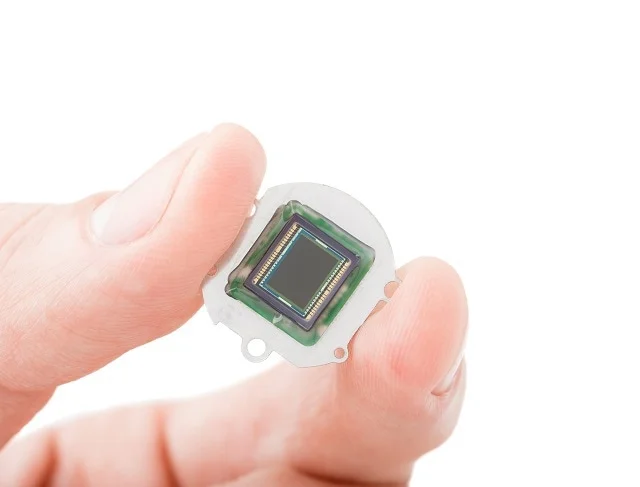

MEMS accelerometers, also known as Micro-Electro-Mechanical Systems accelerometers, are a type of accelerometer that utilize microfabrication techniques to create miniature devices capable of measuring acceleration. MEMS accelerometers have become widely used due to their small size, low cost, and reliable performance.

These accelerometers consist of tiny silicon-based structures with movable masses suspended by flexible beams or springs. When subjected to acceleration, the mass deflects from its equilibrium position, causing changes in capacitance, resistance, or piezoelectric effects. These changes are then measured and converted into electrical signals that represent the applied acceleration.

MEMS accelerometers can measure both static (gravity) and dynamic acceleration in multiple axes. They come in single-axis, dual-axis, and three-axis configurations, allowing for measurement in one, two, or three directions respectively. Some MEMS accelerometers also incorporate additional features such as temperature compensation, built-in self-test capabilities, and digital interfaces.

MEMS accelerometers advantages and applications:

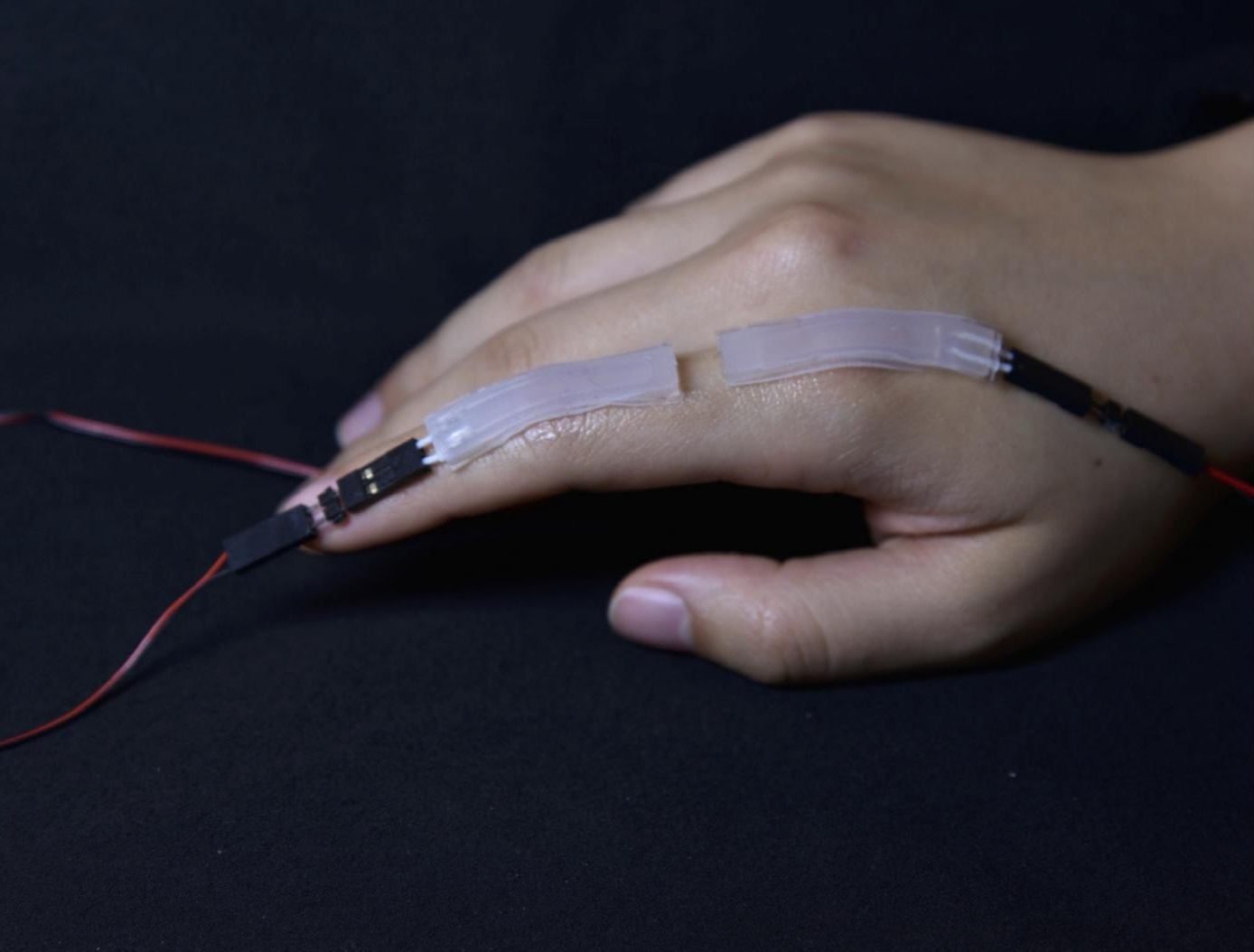

The small size and low power consumption of MEMS accelerometers make them suitable for various applications, including mobile devices, automotive systems, gaming controllers, industrial equipment monitoring, and wearable devices. They play a crucial role in motion sensing applications, such as detecting orientation changes, vibration analysis, navigation, and gesture recognition.

Overall, MEMS accelerometers offer reliable and highly accurate measurement of acceleration in a compact form factor, making them essential components in numerous technological advancements.

Choosing an accelerometers

When choosing an accelerometer, there are several factors to consider:

Sensitivity

The sensitivity of an accelerometer determines how well it can detect small changes in acceleration. Higher sensitivity allows for the measurement of smaller accelerations, but it may also introduce noise. Consider the level of sensitivity required for your specific application.

Dynamic Range

The dynamic range refers to the range of accelerations that an accelerometer can measure accurately. It is important to select an accelerometer with a dynamic range that covers the expected range of accelerations in your application. A wide dynamic range ensures accurate measurements even in high-acceleration scenarios.

Frequency Response

The frequency response of an accelerometer determines its ability to measure acceleration across a range of frequencies. Consider the frequency range of the vibrations or movements you need to measure and ensure that the accelerometer has a frequency response that matches your requirements.

Noise Performance

The noise level of an accelerometer can affect the accuracy of measurements. Lower noise performance results in cleaner data. Look for accelerometers with low noise levels if precision is crucial.

Power Consumption

Different applications have varying power requirements. If you are designing a battery-operated or low-power device, consider the power consumption of the accelerometer and choose one that aligns with your power constraints.

Output Type

Accelerometers can have analog or digital outputs. Analog outputs provide continuous voltage or current signals proportional to the acceleration, while digital outputs offer discrete digital values. Choose the output type that best suits your system requirements and compatibility.

These are some factors which would help you when choosing an accelerometers and you should consider them.

By considering these factors, you can choose an accelerometer that meets the specific needs of your application, ensuring accurate and reliable acceleration measurements.

Please note that Like any other sensors, accelerometers require calibration to ensure accurate measurements. Calibration involves compensating for any biases or errors introduced during the manufacturing process or due to environmental factors.