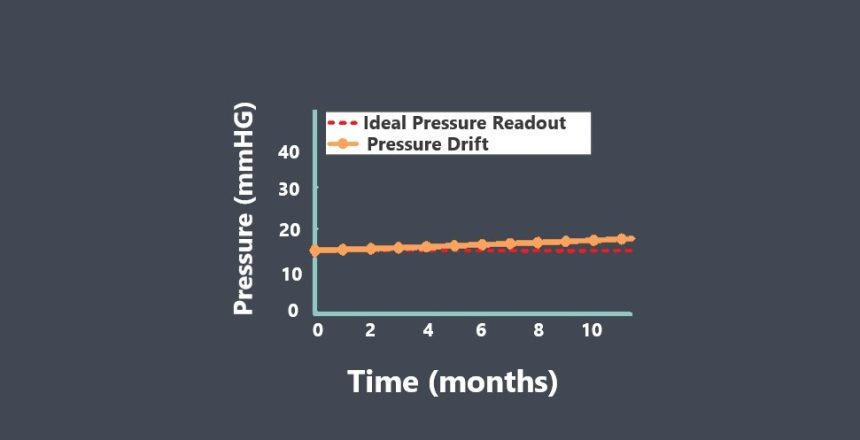

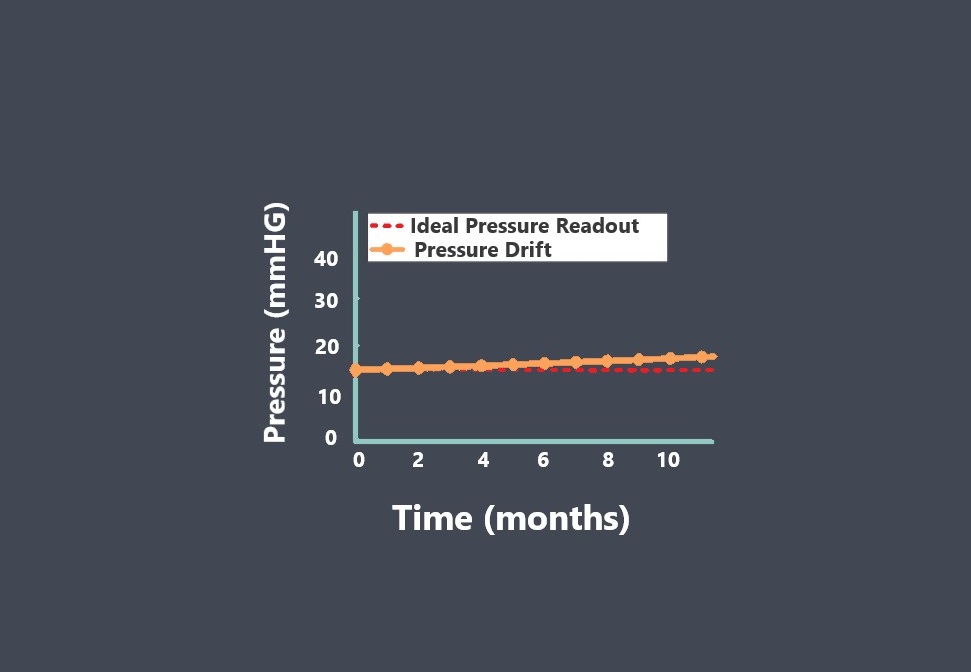

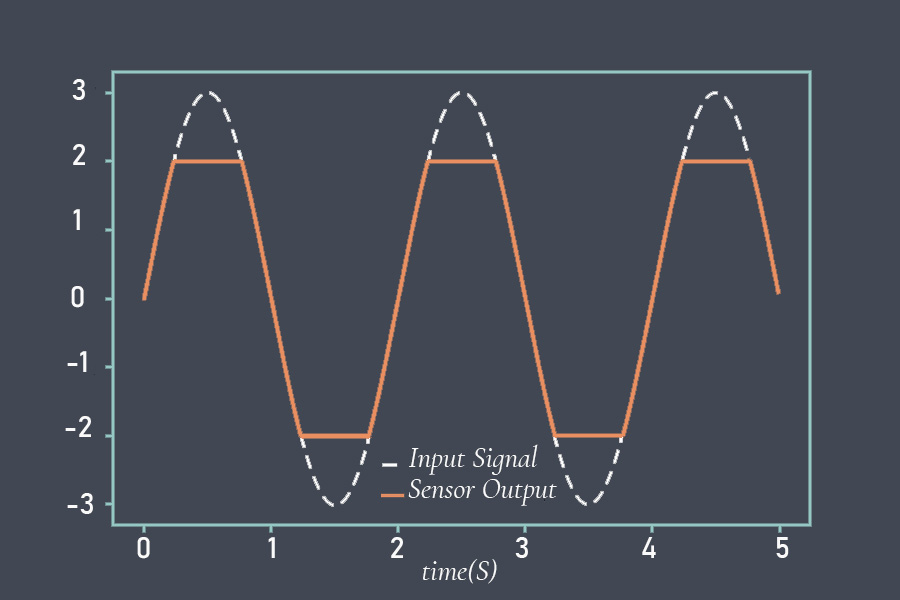

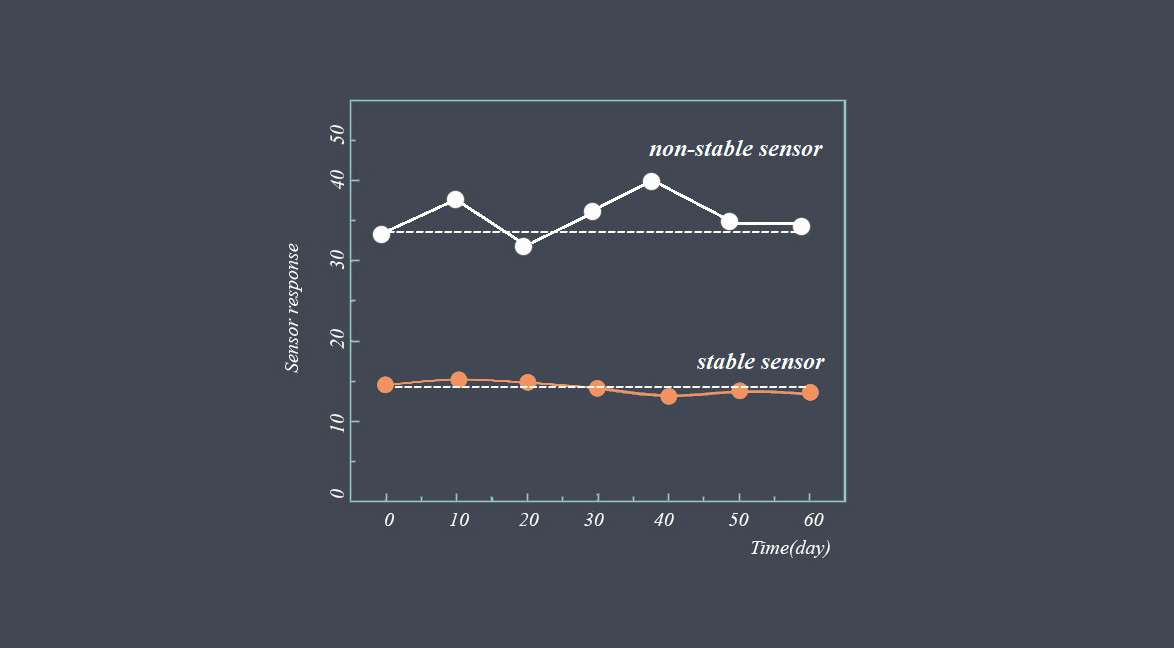

Drift is an important parameter in sensor technology that describes the gradual change in the sensor’s output signal over time, even when the input signal remains constant. It refers to the shift or deviation from the initial calibration or baseline value. Over time, sensors may exhibit changes in their output values, resulting in inaccurate measurements if not accounted for. Drift can occur due to factors such as temperature variations, aging of components, or environmental influences.

Sensor drift types

Drift can be categorized into three types:

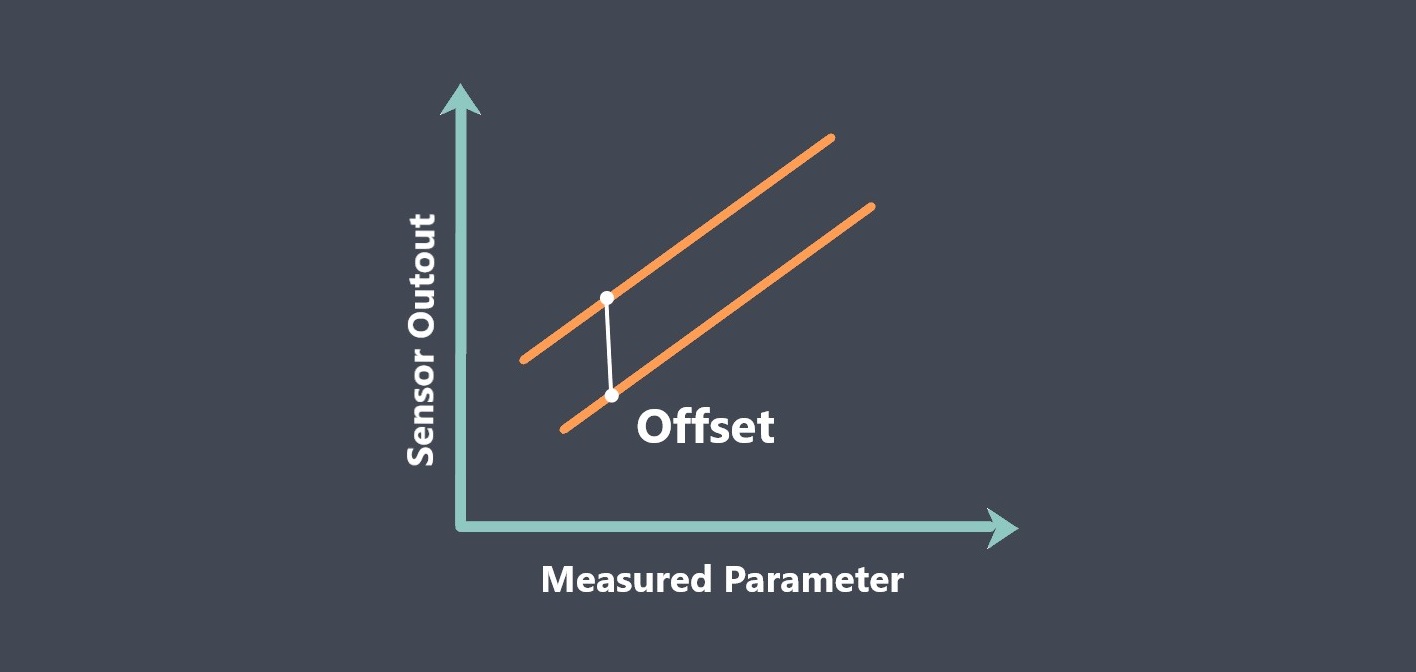

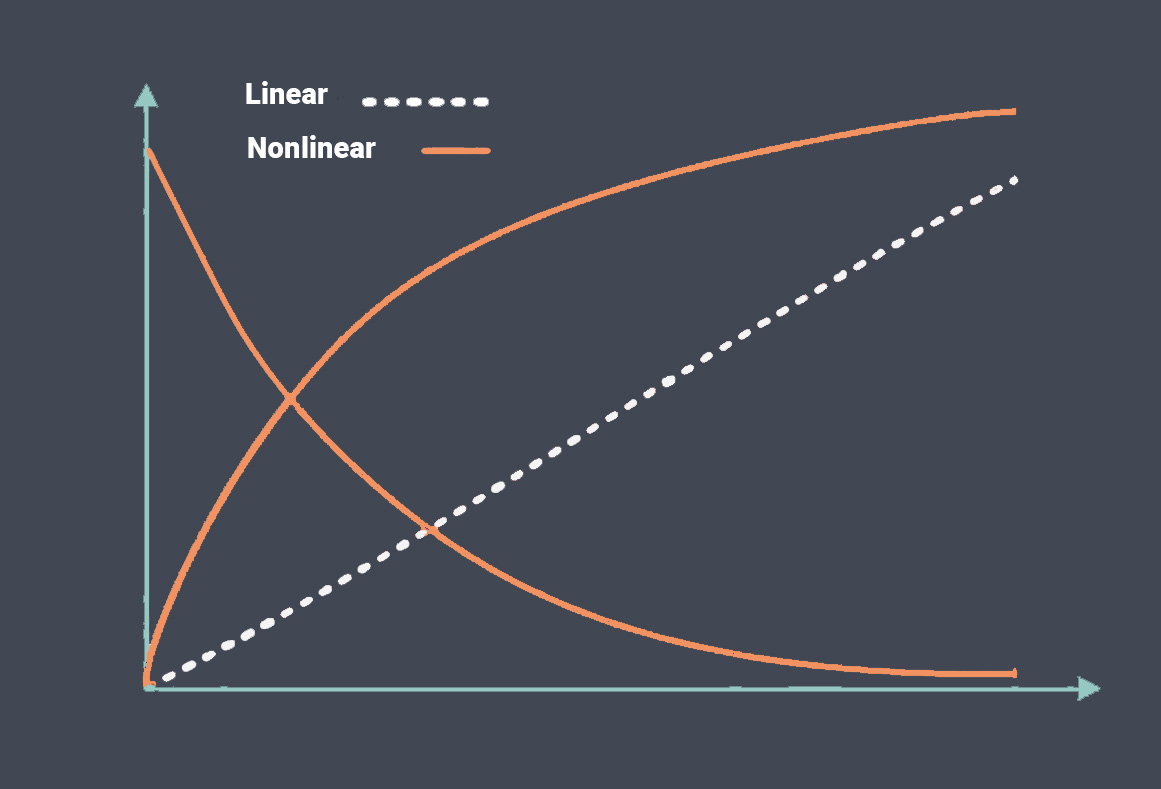

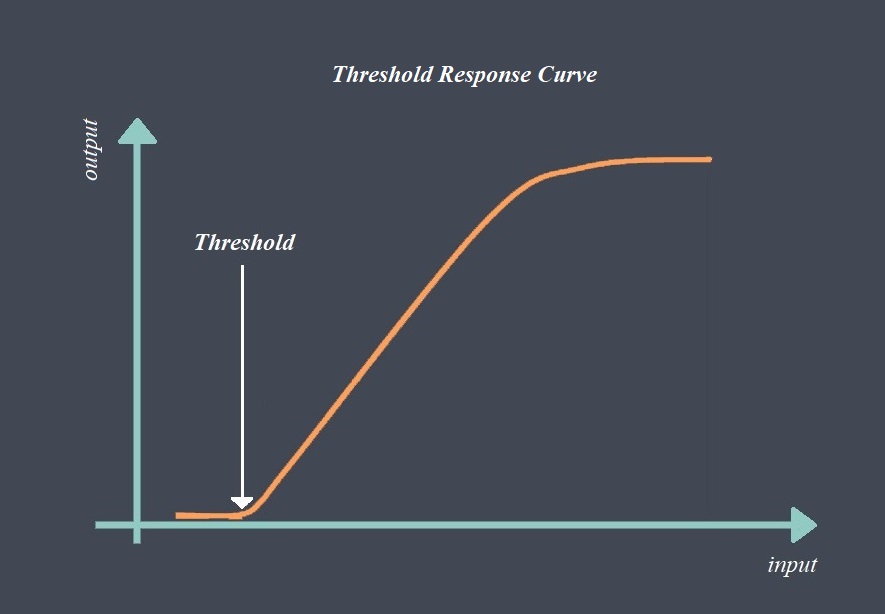

- zero drift: zero drift refers to a change in the sensor’s output when there is no input signal

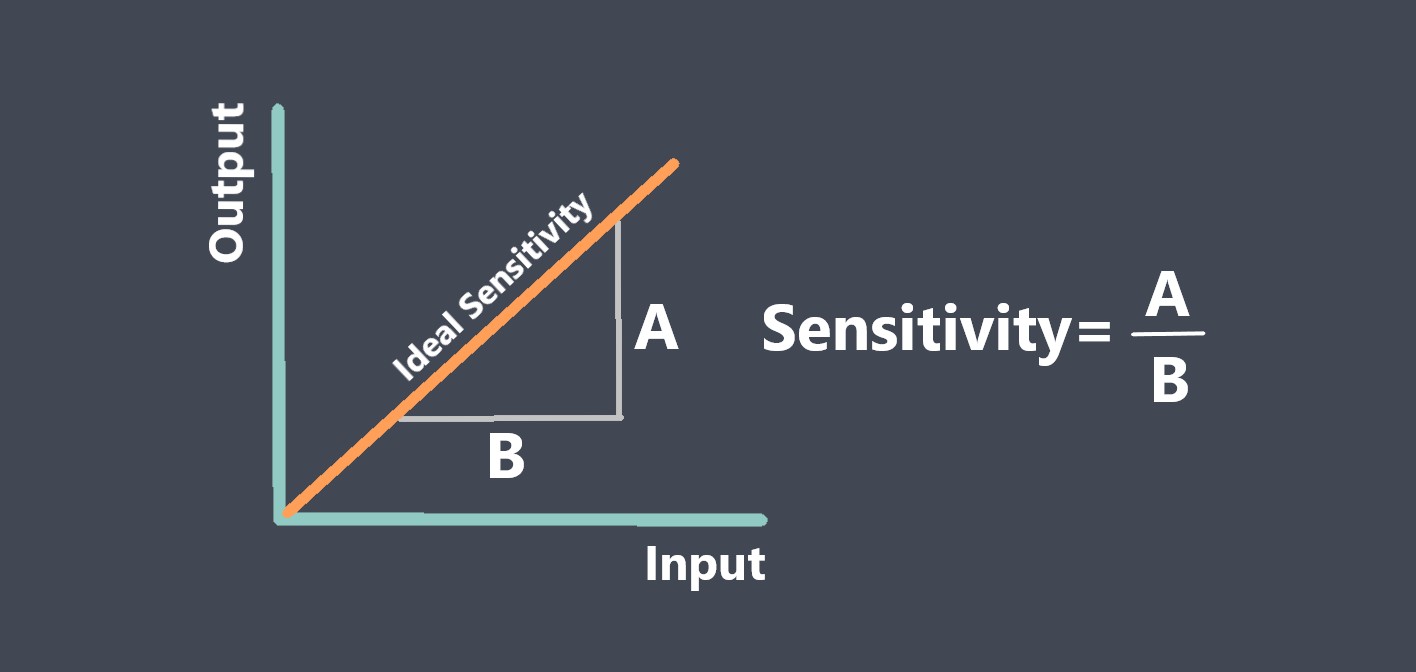

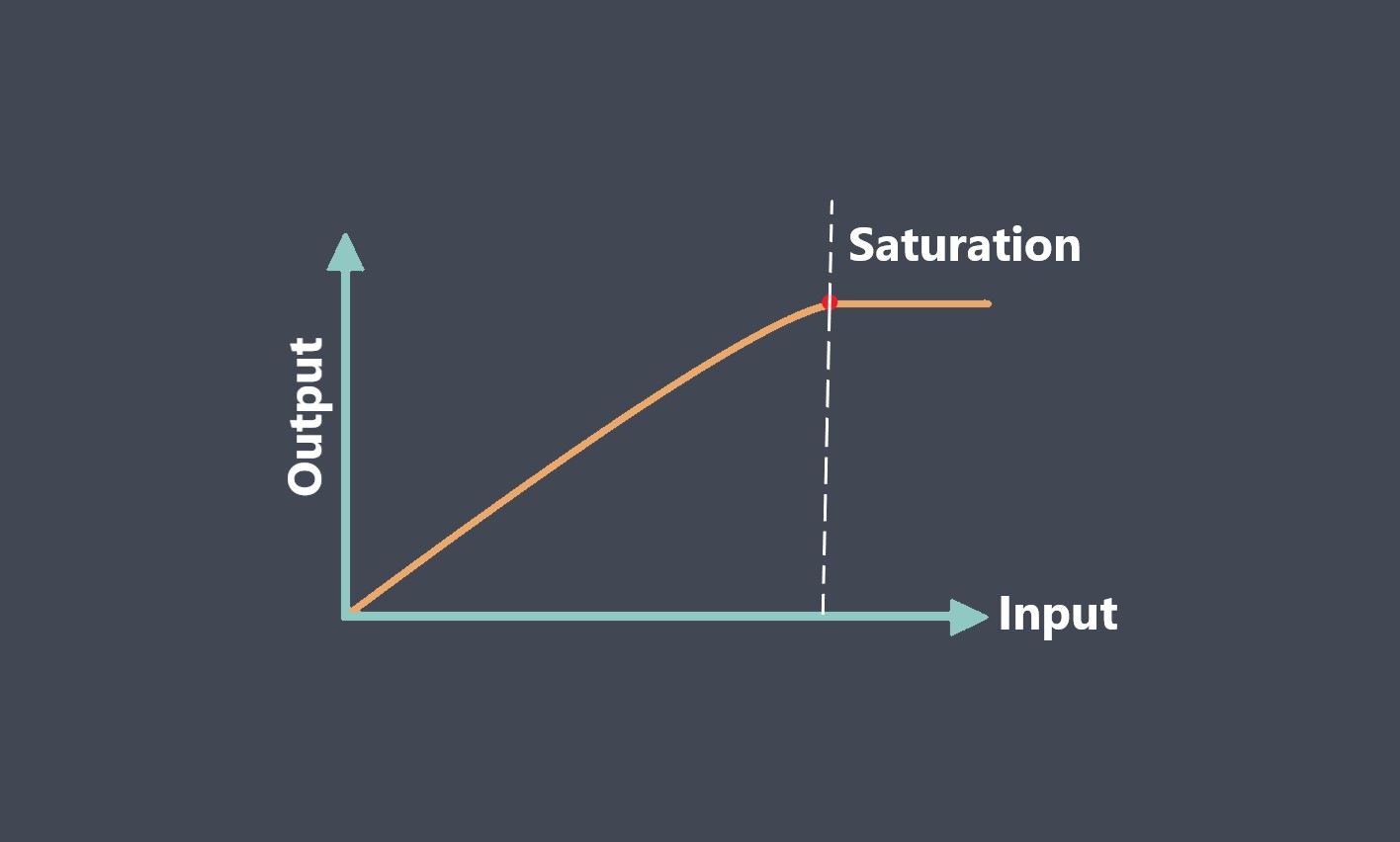

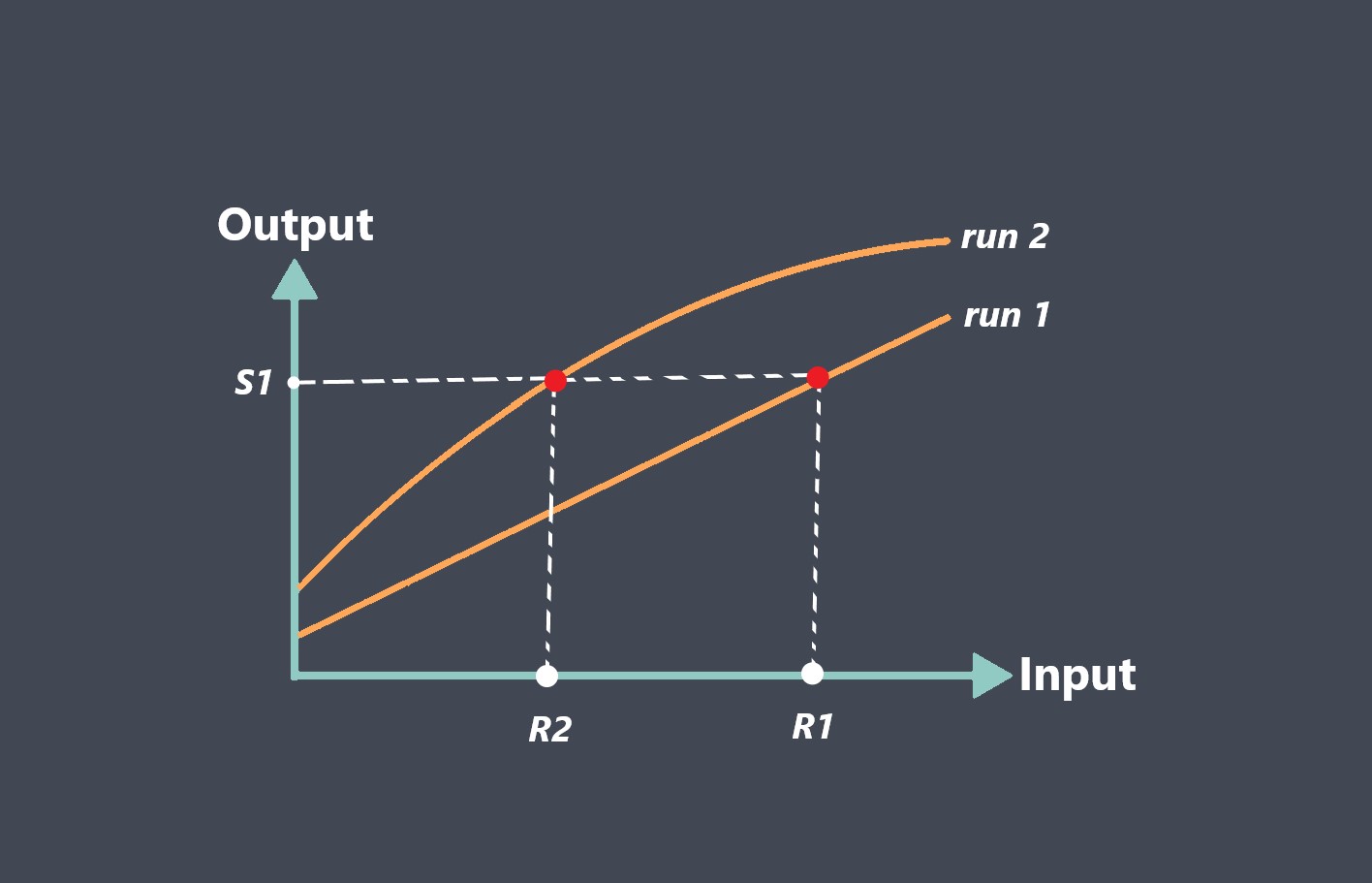

- span drift or sensitivity drift: span drift refers to a change in the slope or gain of the sensor’s transfer function.

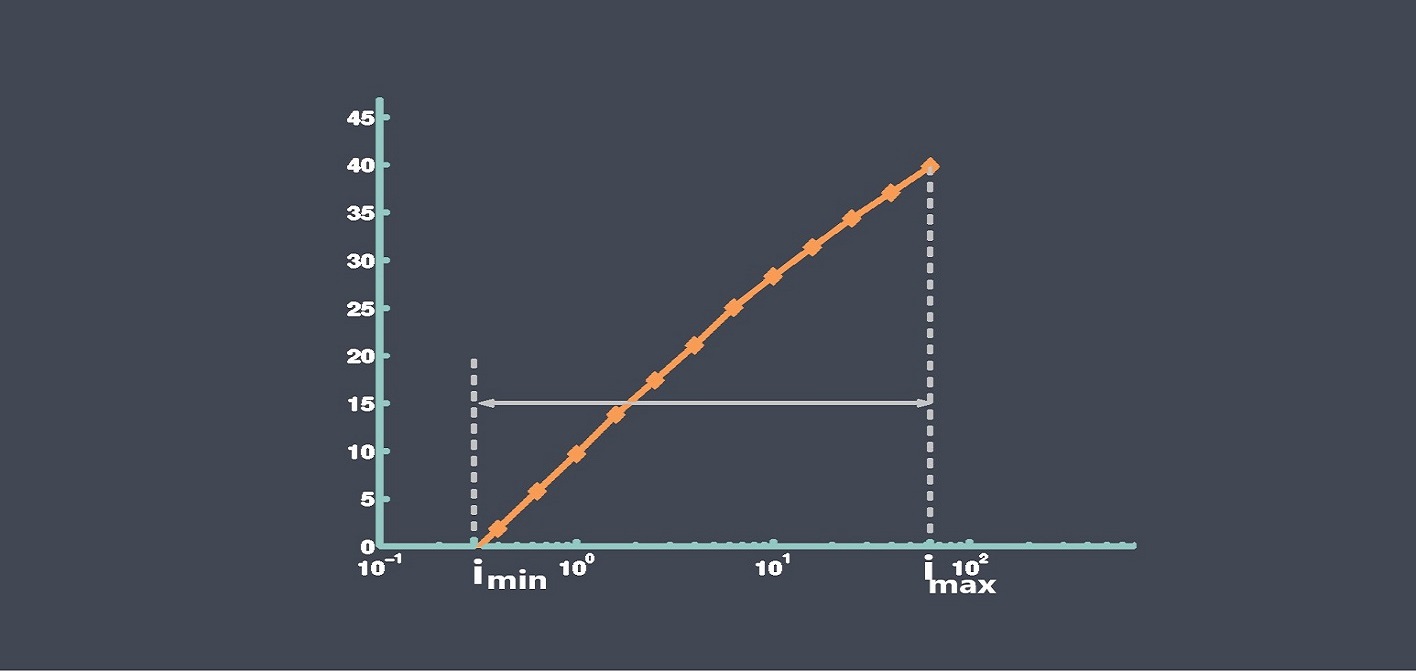

- zonal drift: when the drift occur just over a part of a limited area of an instrument it’s called zonal drift.

Factors affecting sensor drift

Sensor drift can occur due to various factors, including:

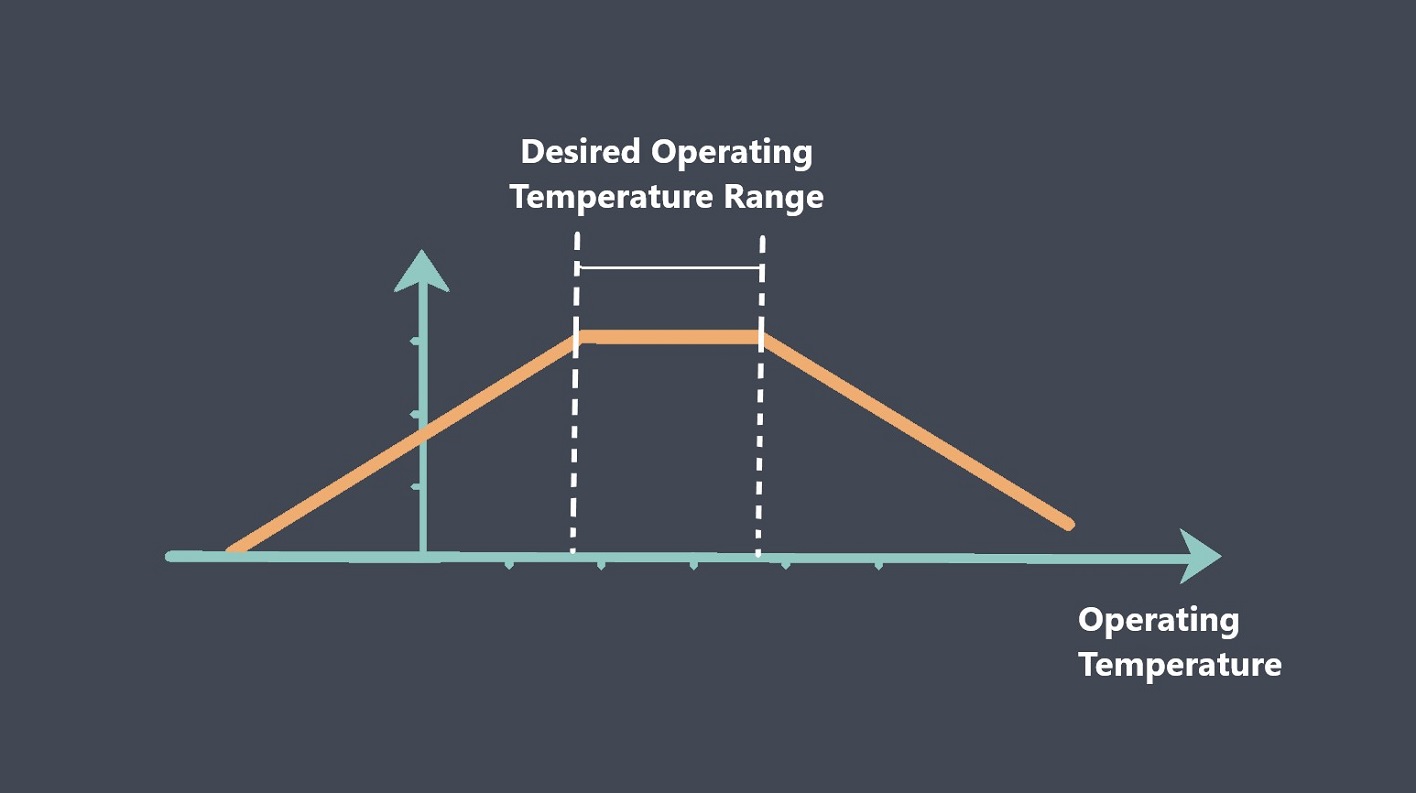

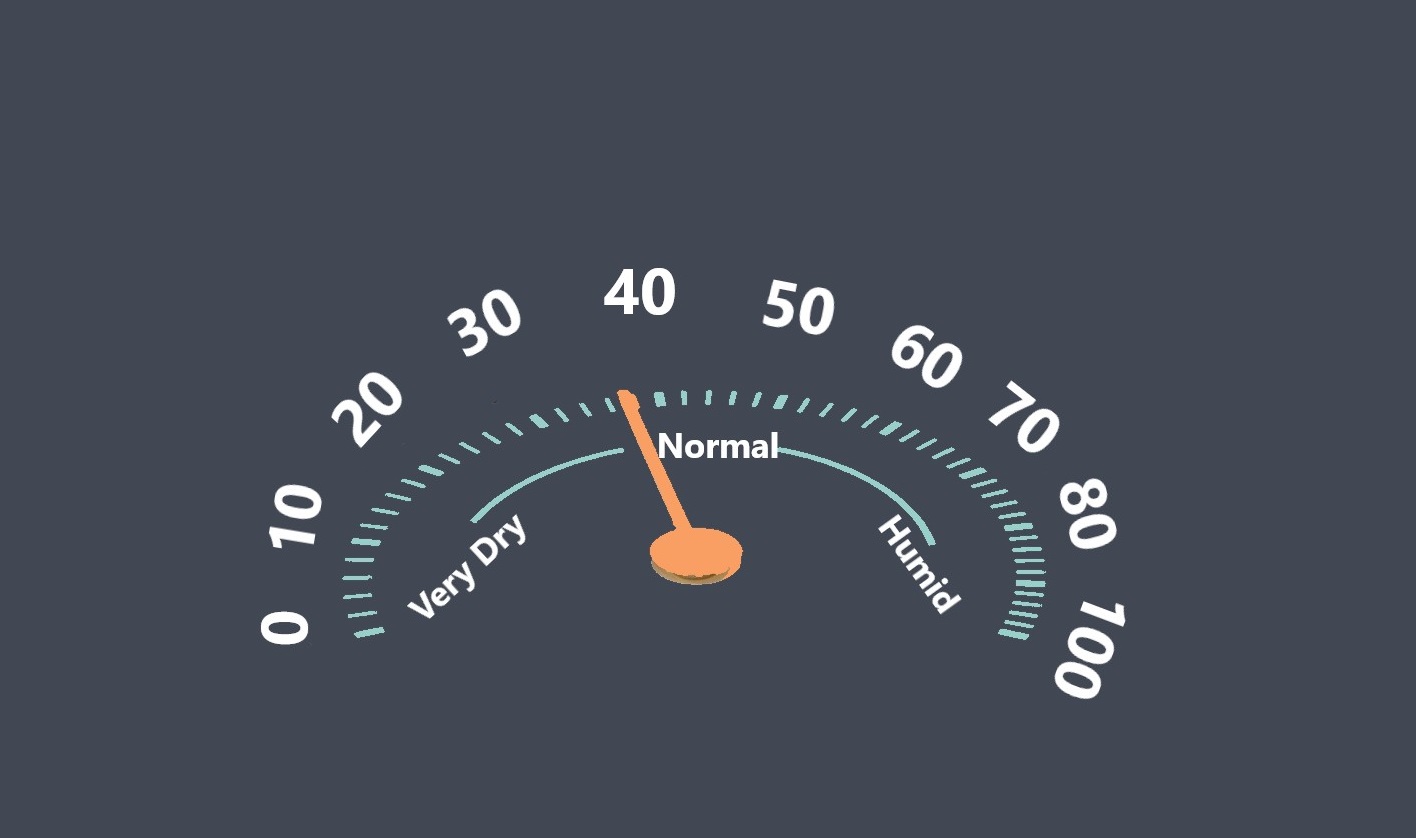

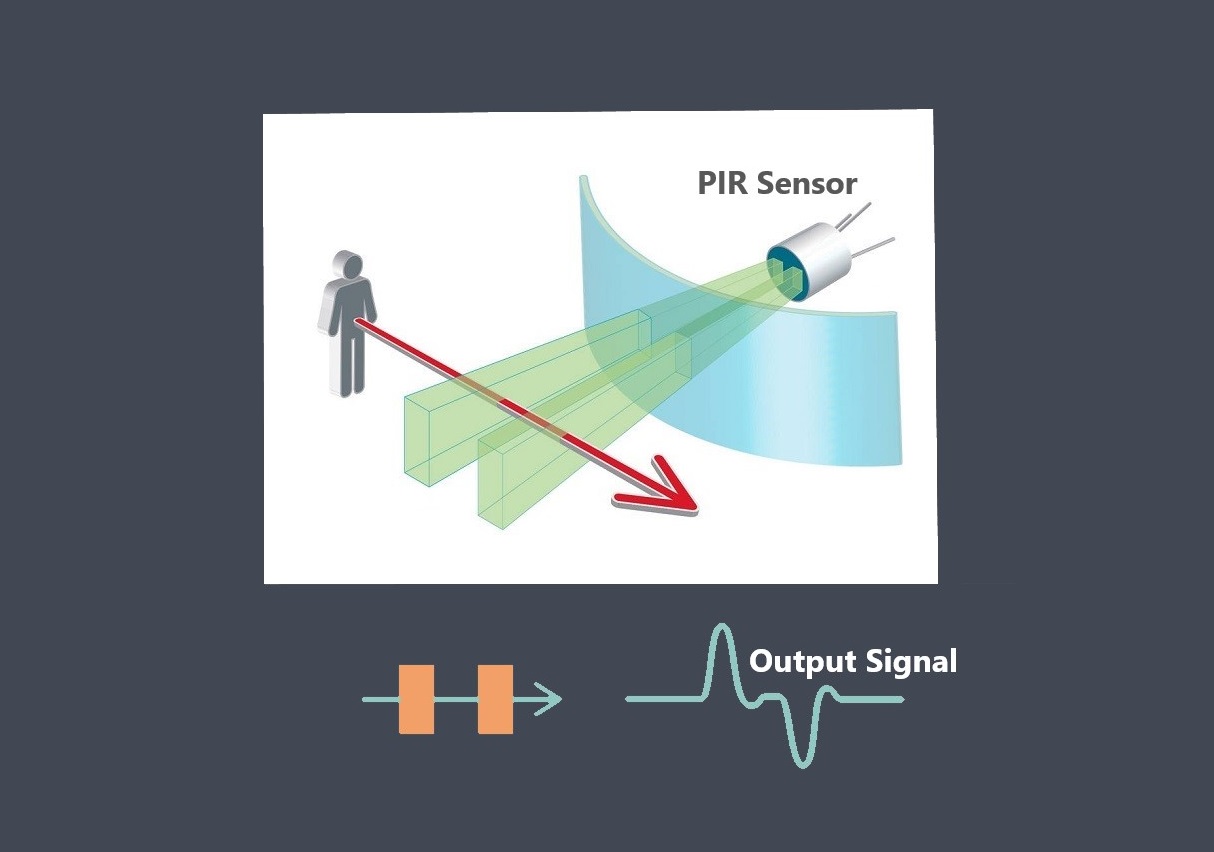

Environmental Factors

Changes in temperature, humidity, pressure, or other environmental conditions can affect the performance of sensors. These factors can lead to physical changes within the sensor components, causing drift.

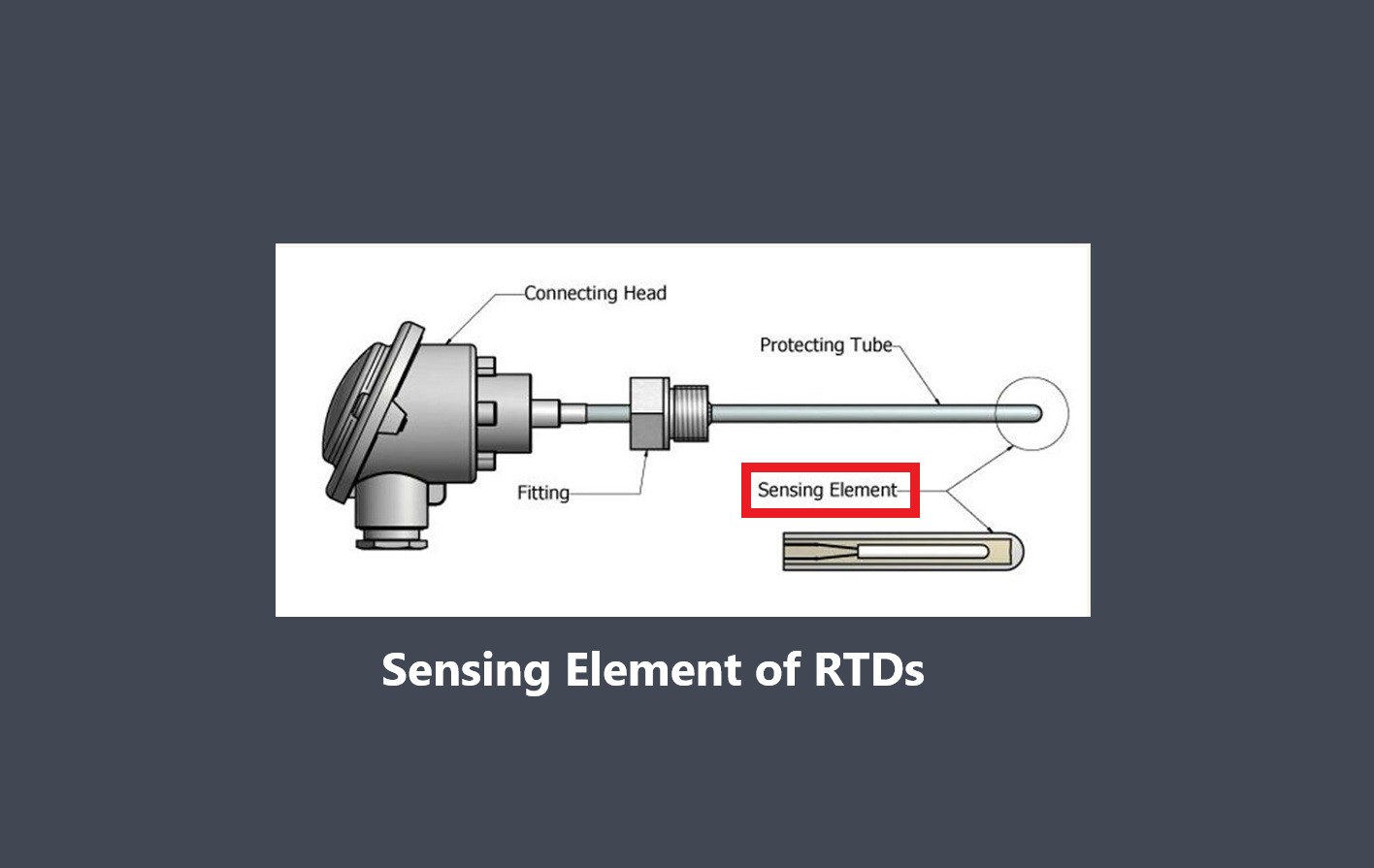

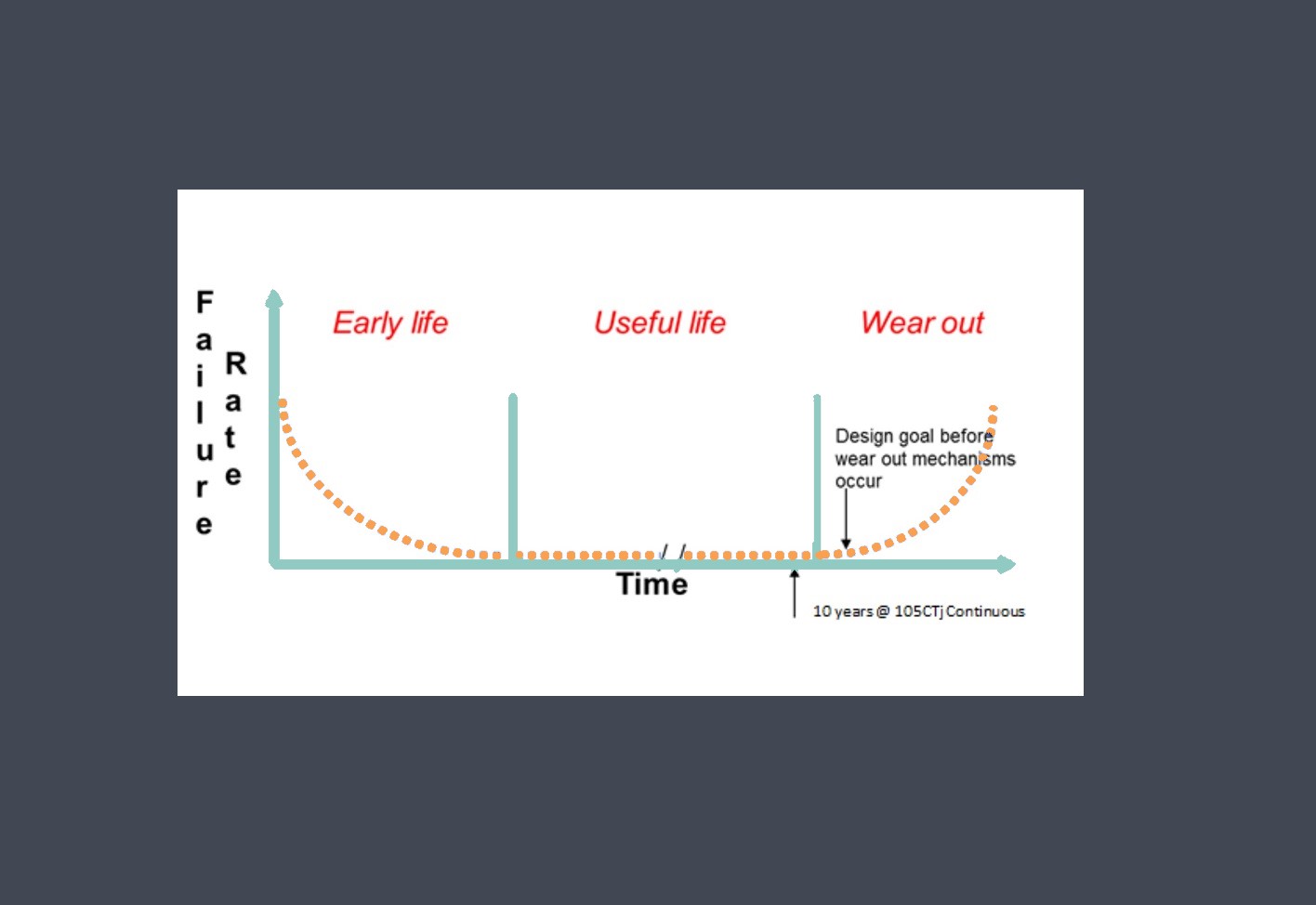

Aging and Wear

Over time, the internal components of a sensor may undergo aging or wear, which can result in changes in their electrical or mechanical properties. This can cause the sensor’s output to deviate from its initial calibration.

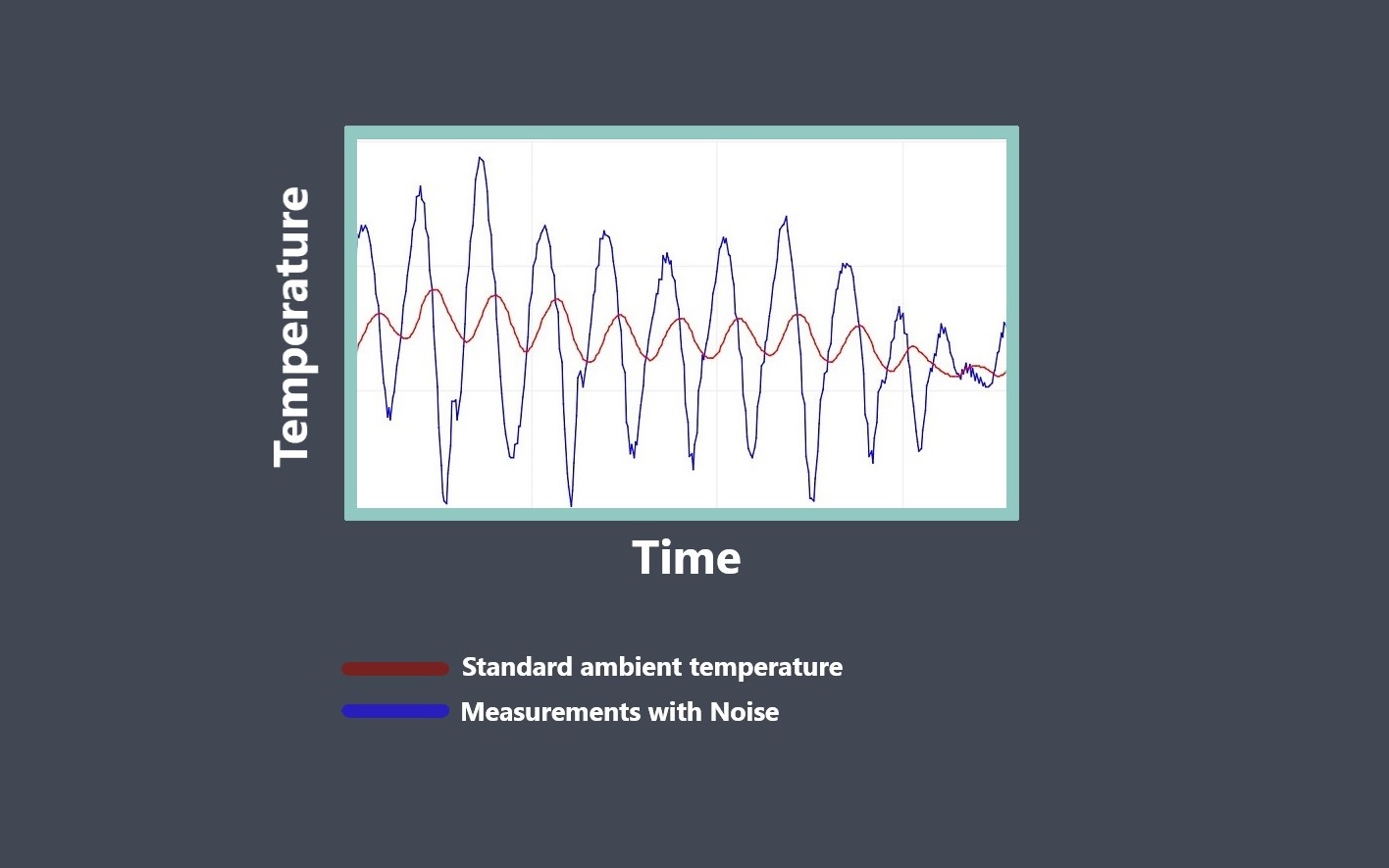

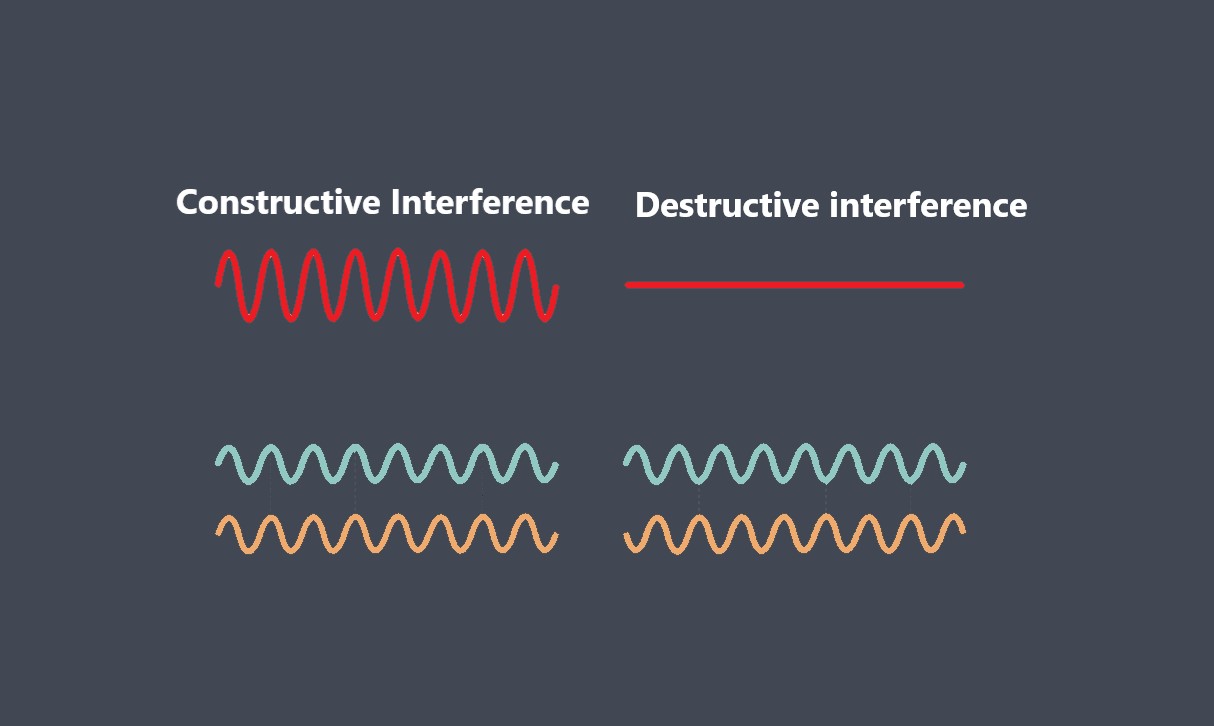

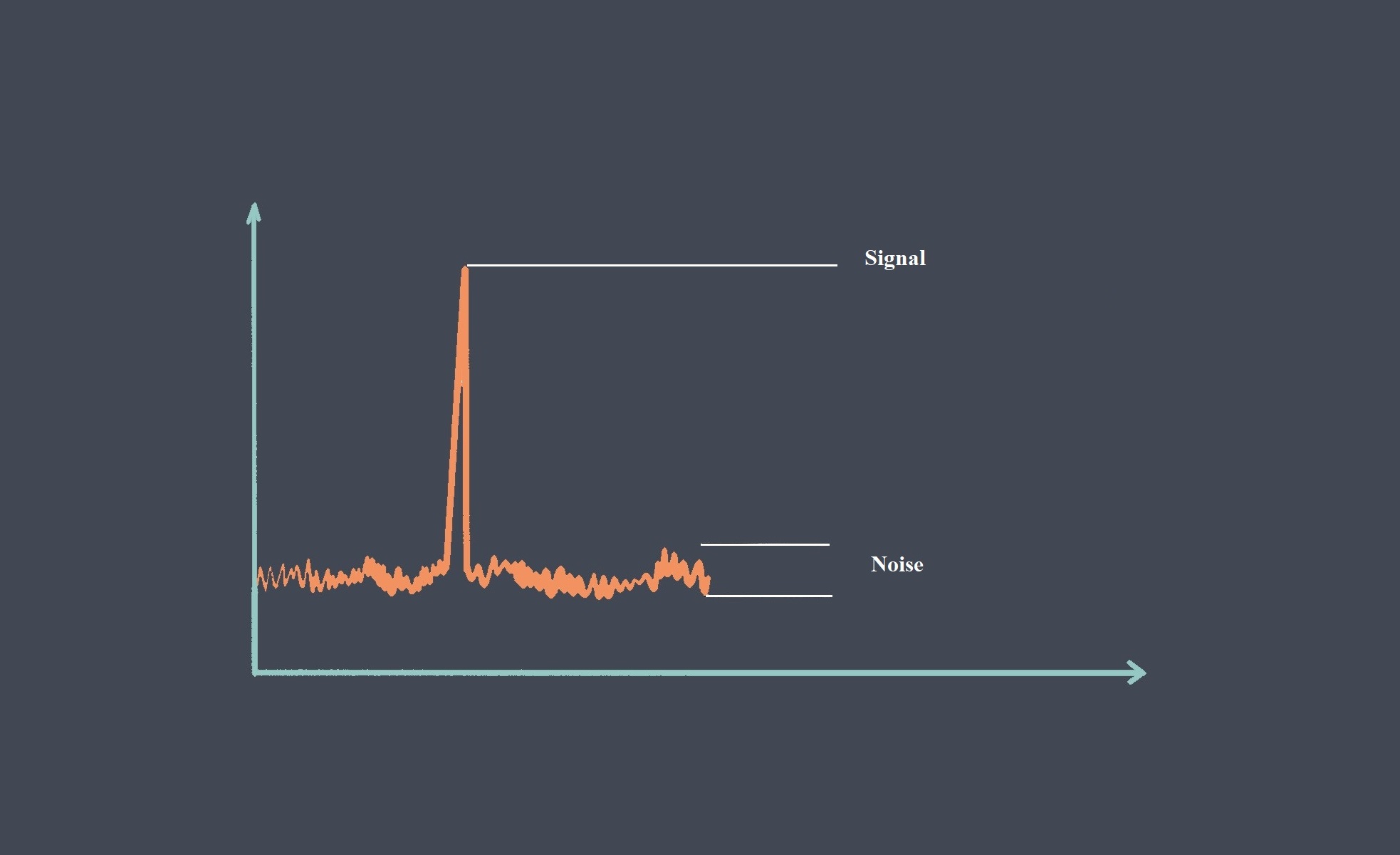

Electronic Noise

Electrical noise within the sensor or in the surrounding environment can interfere with the signal processing circuitry, leading to inaccurate readings and drift.

Contamination

Sensors may be exposed to contaminants such as dust, moisture, or chemicals, which can accumulate on the sensing elements or interfere with the sensor’s electronics. This contamination can impact the sensor’s performance over time.

Manufacturing Variations

Variations in the manufacturing process can introduce inherent differences between individual sensors of the same type. These variations may cause slight differences in sensor characteristics, resulting in drift.

Can the drift of the sensor be reduced to zero?

In theory, it is possible to reduce the drift of a sensor to zero. However, in practice, achieving absolute zero drift is extremely challenging and often not feasible. Sensor drift refers to the gradual changes in the output of a sensor over time, even when the measured quantity remains constant.

Drift can be caused by various factors such as temperature fluctuations, aging of components, mechanical stress, environmental conditions, and electronic noise. While these factors can be minimized through careful design, calibration, and manufacturing processes, it is difficult to completely eliminate them.

It’s important to note that the acceptable level of drift depends on the specific application and requirements. In certain cases, the drift may be negligible and does not significantly affect the sensor’s performance. In other applications where high precision is crucial, efforts are made to minimize drift as much as possible, but reaching absolute zero drift is typically impractical.

How to mitigate the effects of drift?

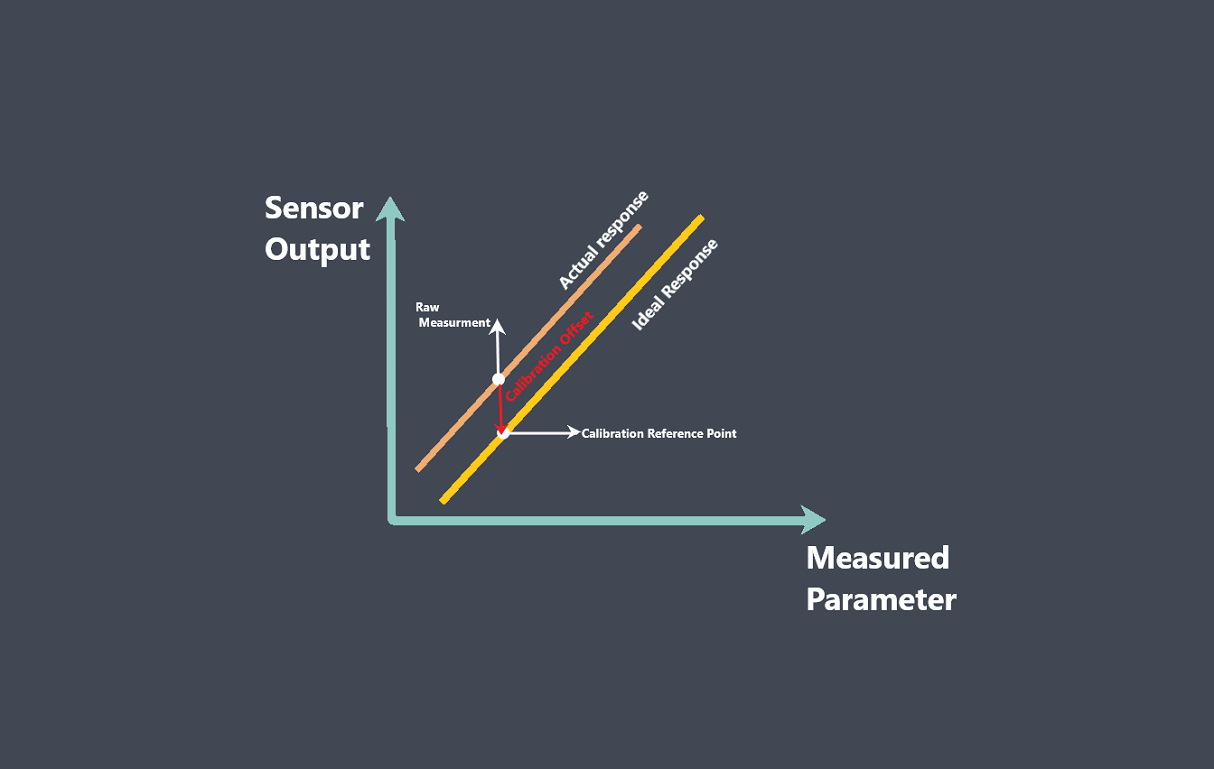

To mitigate the effects of drift, sensor calibration and compensation techniques are employed. Calibration involves periodically comparing the sensor’s output to a known reference value and adjusting the sensor’s response accordingly. This recalibration process corrects for any drift and ensures the accuracy of the sensor’s measurements.

Compensation techniques aim to minimize or eliminate drift by incorporating temperature sensors, control circuitry, or algorithms that dynamically adjust the sensor’s output based on environmental changes. These techniques can help maintain the sensor’s performance within acceptable limits over an extended period.

It’s important to note that not all sensors exhibit significant drift, and the magnitude and rate of drift can vary depending on the sensor type, design, and operating conditions. Understanding the drift characteristics of a sensor is crucial for applications that require long-term stability and accuracy.

How to find out about the drift of your sensor?

To find out about the drift of your sensor, you can follow these steps:

Understand Sensor Drift

Sensor drift refers to the gradual change in output or readings of a sensor over time. It can be caused by various factors such as aging, environmental conditions, electrical interference, etc.

Establish Baseline

Start by establishing a baseline reading for your sensor when it is newly calibrated or known to be accurate. This will serve as a reference point for comparison.

Regular Calibration

Regularly calibrate your sensor according to the manufacturer’s guidelines or industry standards. Calibration helps correct any deviations and provides accurate measurements.

Periodic Measurements

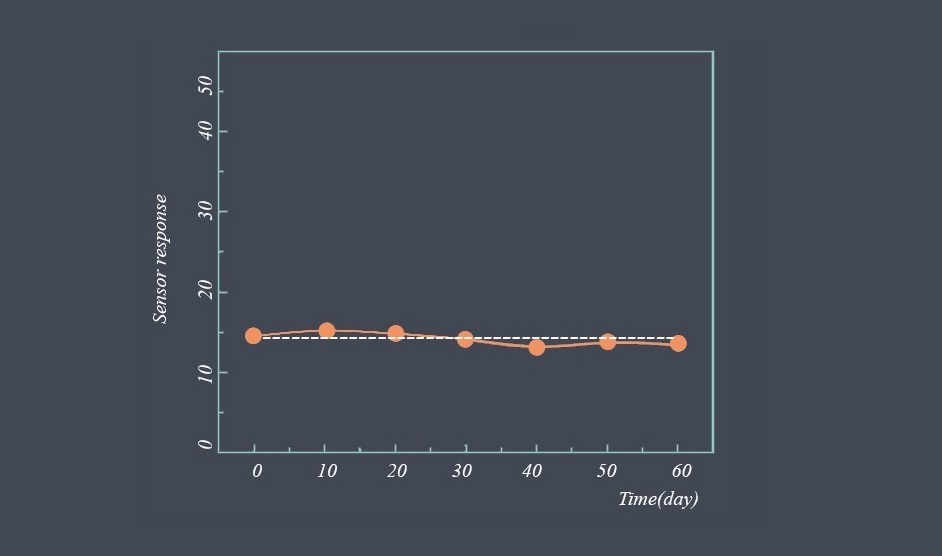

Take periodic measurements using your sensor. Depending on the application and sensor type, you might take readings daily, weekly, monthly, or at specific intervals.

Record Readings

Keep a detailed log of all the readings obtained from your sensor along with corresponding timestamps.

Data Analysis

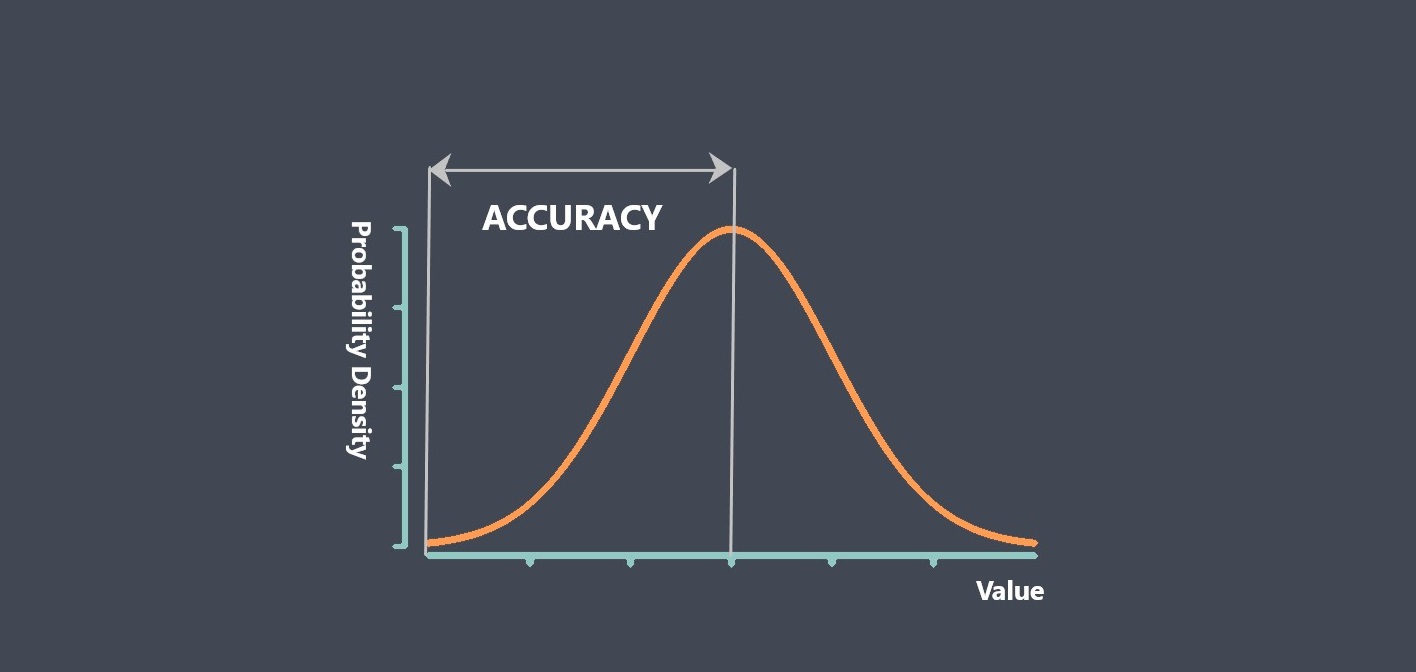

Analyze the collected data to detect any trends or patterns. Look for deviations from the baseline reading or any consistent changes in the measurements over time.

Statistical Analysis

Apply statistical methods to assess the drift. You can calculate statistical parameters like mean, standard deviation, and variance of the recorded readings. Plotting the data on graphs or control charts can also help visualize the drift.

Compare with Specifications

Refer to the sensor specifications provided by the manufacturer or required tolerances for your application. Compare the measured values against the specified range to determine if the drift is within acceptable limits.

Identify Causes

If you observe significant drift, try to identify potential causes. Consider factors such as environmental conditions, aging components, power supply issues, or improper handling that may contribute to the drift.

Maintenance and Troubleshooting

Perform regular maintenance tasks recommended by the sensor manufacturer. If the drift is excessive or problematic, consult the manufacturer’s support or seek assistance from experts in the field.

Remember, the specific methods for analyzing and managing sensor drift may vary depending on the type of sensor you are using. Always refer to the manufacturer’s documentation and guidelines for accurate assessment and troubleshooting.