These sensors detect and measure magnetic fields, and are commonly used in automotive, robotics, and industrial automation.

what is Hall effect

The Hall effect is a phenomenon discovered by Edwin Hall in 1879. It refers to the production of a voltage difference (Hall voltage) across an electrical conductor or semiconductor material when it is subjected to a magnetic field perpendicular to the direction of current flow.

When a current-carrying conductor or semiconductor is placed in a magnetic field, the Lorentz force acts on the moving charge carriers (electrons or holes). This force pushes the charge carriers towards one side of the conductor, resulting in an accumulation of charge on that side. As a result, an electric field is generated, which creates a voltage difference between the two sides of the conductor. This voltage difference is known as the Hall voltage.

The name of this law is derived from the name of the Dutch physicist Hendrik Lorentz who first described this force. According to this, The Lorentz force is the force experienced by a charged particle moving through a magnetic field.

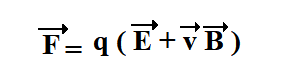

The Lorentz force (F) acting on a charged particle with charge q moving with velocity v in a magnetic field B can be calculated using the following equation:

where

- F is the electromagnetic force on a test charge

- q is the particle’s electric charge

- v is the velocity

- E refers to the external electric field

- B is the magnetic field

The magnitude of the Hall voltage depends on various factors, such as the strength of the magnetic field, the current flowing through the conductor, and the type of charge carriers present. The Hall effect can be described by the equation:

Where

VH is the Hall voltage,

B is the magnetic field strength,

I is the current flowing through the conductor,

d is the thickness of the conductor,

n is the charge carrier density,

q is the charge of the carriers.

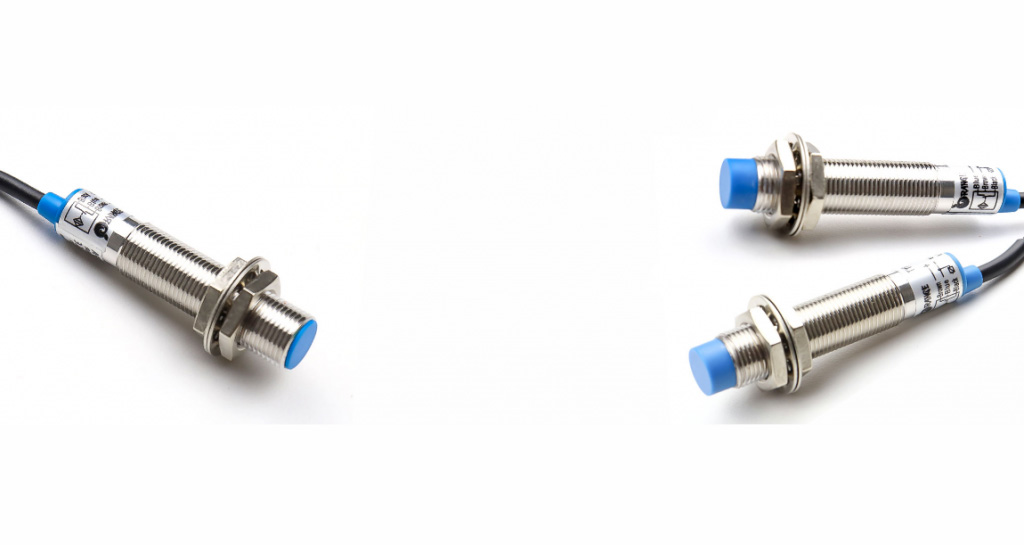

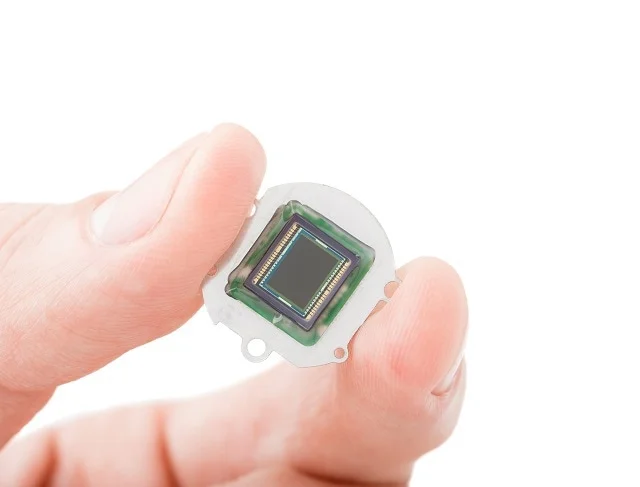

Hall effect sensors

Hall-effect sensors are electronic devices that are used to detect the presence, position, and strength of a magnetic field. They utilize the Hall effect, which is the production of a voltage difference across an electrical conductor when subjected to a magnetic field perpendicular to the current flow.

The basic operation of a Hall-effect sensor involves a thin strip of conducting material, typically made of semiconductor material. When a magnetic field is applied perpendicular to the direction of current flow in the strip, it creates a Lorentz force on the charge carriers (electrons or holes) within the material. This force causes a buildup of charge on one side of the strip, resulting in a voltage difference between the two sides.

Hall effect sensors types

Hall effect sensors can be categorized based on their output types and their applications. Here are the common categories of Hall effect sensors:

Digital Output Hall Effect Sensors

Digital output Hall effect sensors, also known as Hall effect switches, provide a digital signal that changes state when a magnetic field exceeds a certain threshold. They are commonly used for proximity sensing, limit switches, and rotational speed sensing applications.

These sensors have a binary output signal, typically represented as “High” or “Low,” “On” or “Off.” The output changes state when the magnetic field crosses a predefined threshold.

In digital output Hall effect sensors, “Schmitt trigger” circuit is used. A Schmitt trigger circuit is a comparator circuit that uses positive feedback. A Schmitt trigger is an active circuit that converts an analog input signal into a digital output signal. In this circuit, when the input voltage exceeds a certain threshold, the output voltage will be 1V which means the key is on the “ON” state. When the input voltage is lower than the threshold value, the output voltage of this circuit will be 0V; it means the key is in the “OFF” state. When this sensor is exposed to a magnetic field or the magnetic field is removed, no oscillation is observed in the output circuit of the sensor due to the presence of the Schmitt trigger circuit.

Digital Hall effect sensors can detect even weak magnetic fields. They are designed to have high sensitivity to ensure reliable and accurate switching.

These sensors offer a fast response time, enabling quick detection and response to changes in the magnetic field. This is beneficial for applications requiring real-time sensing and control.

They often have open-drain or open-collector outputs, which can be directly connected to microcontrollers, PLCs, or other logic devices.

One significant advantage of Hall effect sensors is that they operate without physical contact. They can sense magnetic fields through non-magnetic materials, making them suitable for harsh environments and applications where contact-based sensors may fail.

Unipolar Hall Effect Sensors

Unipolar Hall effect sensors are a type of magnetic sensor that detect the presence and strength of magnetic fields. Unlike bipolar Hall effect sensors, which can detect both north and south poles of a magnet, unipolar sensors can only sense one of the poles.

Unipolar Hall effect sensors are designed to detect the presence of a specific magnetic pole, either north or south. They are typically optimized for sensing one polarity more effectively, providing reliable and accurate detection.

Unipolar Hall effect sensors have a digital output signal that switches between high or low levels based on the presence or absence of the desired pole. They provide a simple on/off response, making them suitable for applications that require a binary detection or proximity sensing.

Unipolar Hall effect sensors can typically operate over a wide temperature range and handle a broad range of magnetic field strengths. They are often used in harsh environments where temperature variations and strong magnetic fields are present.

Many unipolar Hall effect sensors come with built-in reverse polarity protection, ensuring that the sensor is not adversely affected by the accidental reversal of the magnetic field. This feature enhances the sensor’s durability and reliability.

Unipolar Hall effect sensors are known for their low power consumption, making them suitable for battery-powered and energy-efficient applications.

Unipolar Hall effect sensors applications:

Unipolar Hall effect sensors find applications in various industries, including automotive, industrial automation, robotics, consumer electronics, and more. Their simplicity, accuracy, and robustness make them a popular choice for proximity sensing, position detection, speed measurement, and other magnetic field-related applications.

Bipolar Hall Effect Sensors

Bipolar Hall effect sensors are another type of magnetic sensor that, unlike unipolar sensors, can detect both north and south poles of a magnet. They utilize the Hall effect phenomenon to measure magnetic fields and provide valuable information about the strength and polarity of the field.

Bipolar Hall effect sensors can detect and differentiate between both north and south magnetic poles. This makes them versatile for applications where detection of both polarities is required.

Bipolar Hall effect sensors have a wide sensing range, enabling them to measure a broad range of magnetic field strengths accurately. This makes them suitable for applications where the magnetic field intensity may vary significantly.

Similar to unipolar sensors, bipolar Hall effect sensors operate without physical contact with the magnetic field source.

These sensors exhibit temperature stability, meaning they can maintain their accuracy and performance even in varying temperature conditions. This stability is crucial for applications that experience temperature fluctuations.

Many bipolar Hall effect sensors incorporate reverse polarity protection to safeguard the sensor from damage caused by accidental reversal of the magnetic field. This feature enhances the longevity and reliability of the sensor.

Bipolar Hall effect sensors are compact, lightweight, and easy to integrate into electronic circuits and systems. They typically come in small packages, making them suitable for space-constrained applications.

Bipolar Hall effect sensors applications:

Bipolar Hall effect sensors find applications in various industries, including automotive, industrial automation, robotics, medical devices, and more. They are commonly used for speed and position sensing, motor control, contactless switches, and other applications that require accurate and reliable magnetic field detection.

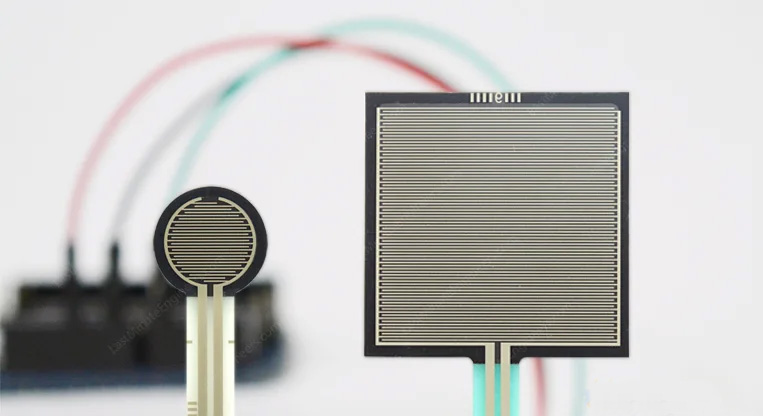

Analog Output Hall Effect Sensors

Analog output Hall effect sensors, as the name suggests, provide an analog output signal that is proportional to the strength of the magnetic field being sensed. These sensors are commonly used in applications that require continuous or precise measurements of magnetic fields.

Analog Hall effect sensors produce a linear voltage or current output that corresponds to the strength of the applied magnetic field. The output signal changes proportionally with the magnetic field strength, allowing for precise measurement and control.

In analog hall effect sensors, the sensor output is directly connected to an amplifier and the signal is taken from the amplifier output.

These sensors can measure a wide range of magnetic field strengths, from weak to strong. They offer high sensitivity and can detect even subtle changes in magnetic fields.

Analog output Hall effect sensors typically have high resolution, enabling accurate measurement and fine-grained control. This is particularly useful in applications where precise measurements are required.

Like digital Hall effect sensors, analog output Hall effect sensors operate without physical contact. They can sense magnetic fields through non-magnetic materials, making them suitable for applications where contact-based sensors may not be feasible.

Many analog output Hall effect sensors include temperature compensation features to maintain accuracy over a wide temperature range. This compensates for any variations in sensor performance due to temperature changes.

Hall effect sensors applications

By measuring this voltage difference, Hall-effect sensors can determine various properties of the magnetic field. Some common applications of Hall-effect sensors include:

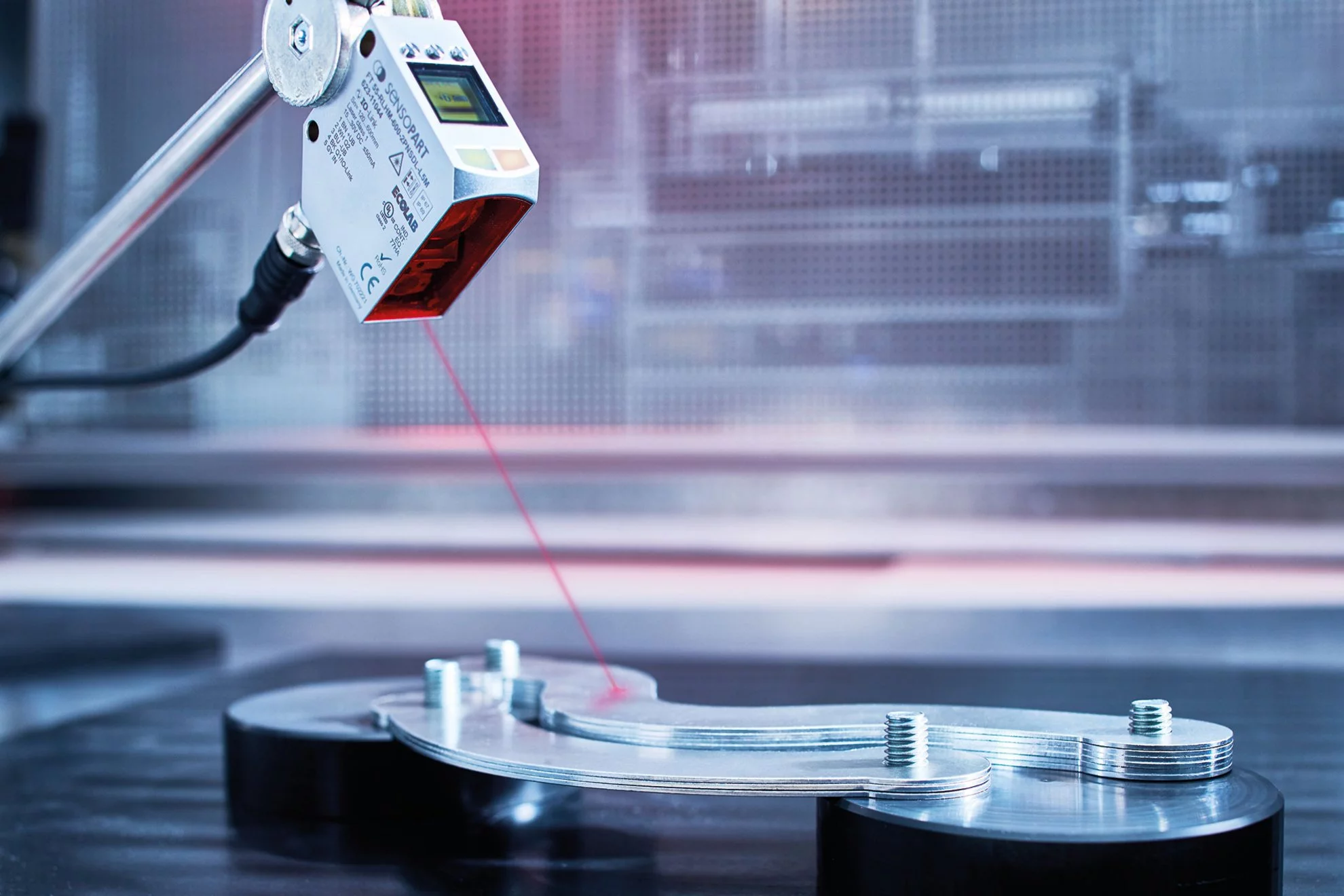

Proximity sensing

Hall-effect sensors can detect the presence or absence of a magnet or a magnetic field. They are commonly used in proximity switches to sense the position of objects or to detect the opening and closing of doors or windows.

Speed sensing

Hall-effect sensors can measure the speed or rotational movement of a magnetized object, such as a wheel or gear. This makes them useful in applications like speedometers, tachometers, and motor control systems.

Current sensing

Hall-effect sensors can measure the flow of electric current through a conductor. They are often used in power electronics to monitor current levels and provide overcurrent protection.

Position sensing

By placing a magnet on a moving object and using a Hall-effect sensor to detect the magnetic field, precise position sensing can be achieved. This is useful in applications such as robotics, linear displacement measurement, and joystick controllers.

Hall-effect sensors offer several advantages, including non-contact operation, high reliability, wide temperature range capability, and resistance to dust, dirt, and moisture. They also have a fast response time and can operate in both DC and AC magnetic fields.

In summary, Hall-effect sensors are versatile devices that can detect, measure, and monitor magnetic fields in various applications. They have found widespread use in industries such as automotive, aerospace, manufacturing, and consumer electronics, contributing to improved functionality and efficiency.

One thought on “Hall effect sensors”

Very clear writing, and I understood the subject without much jargon, thanks for the