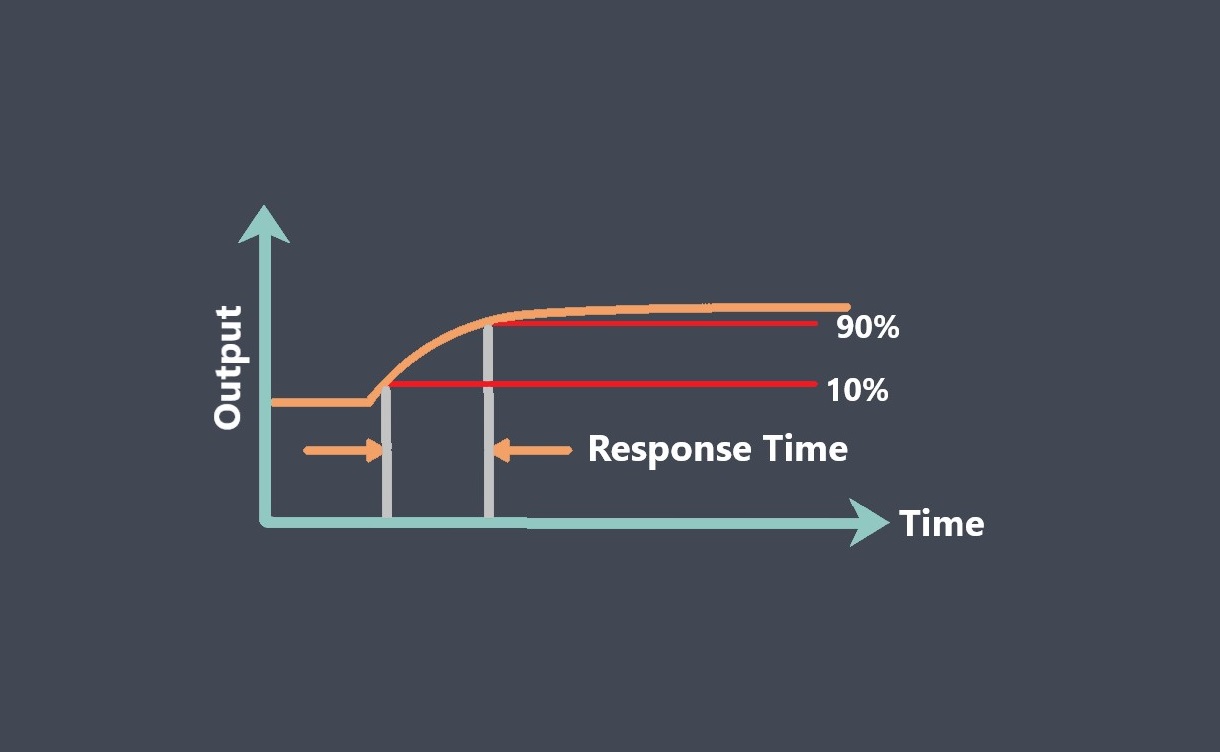

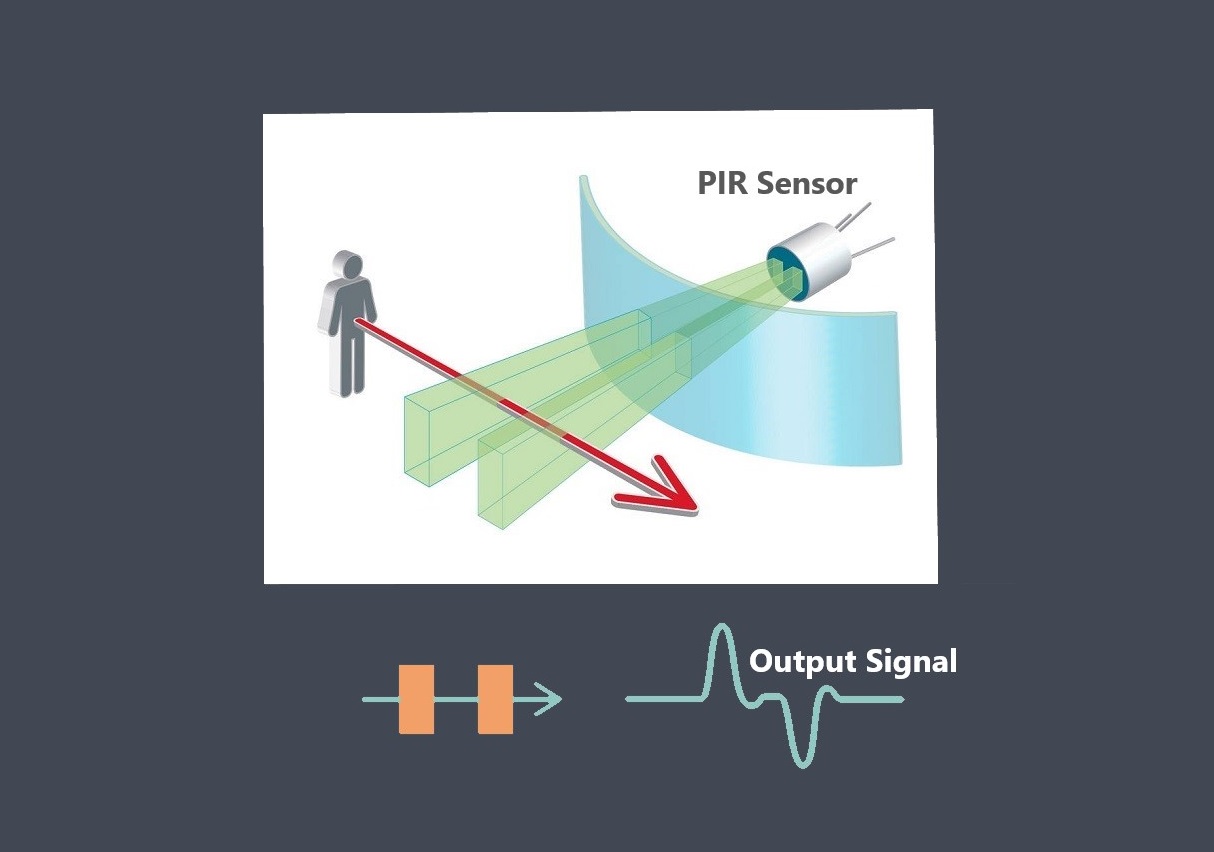

Sensor reliability refers to the ability of a sensor to consistently perform its intended function accurately and dependably over a specified period of time. It is a measure of the sensor’s ability to provide reliable and consistent measurements without unexpected failures or significant degradation in performance.

Reliability is a critical factor for sensors, especially in applications where precise and trustworthy data is required. It ensures that the sensor can be trusted to provide accurate and consistent measurements over its operational lifespan. A reliable sensor is one that can be confidently used in various environments and conditions without compromising data quality.

Key aspects of sensor reliability

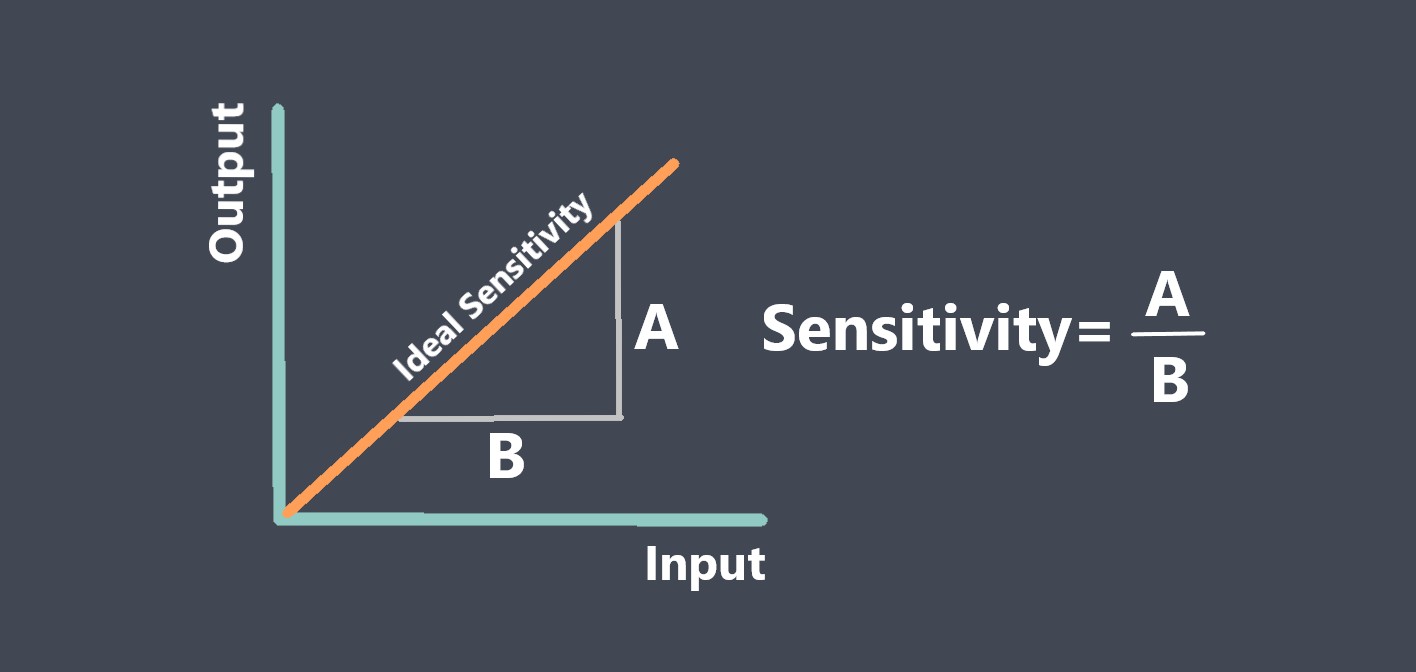

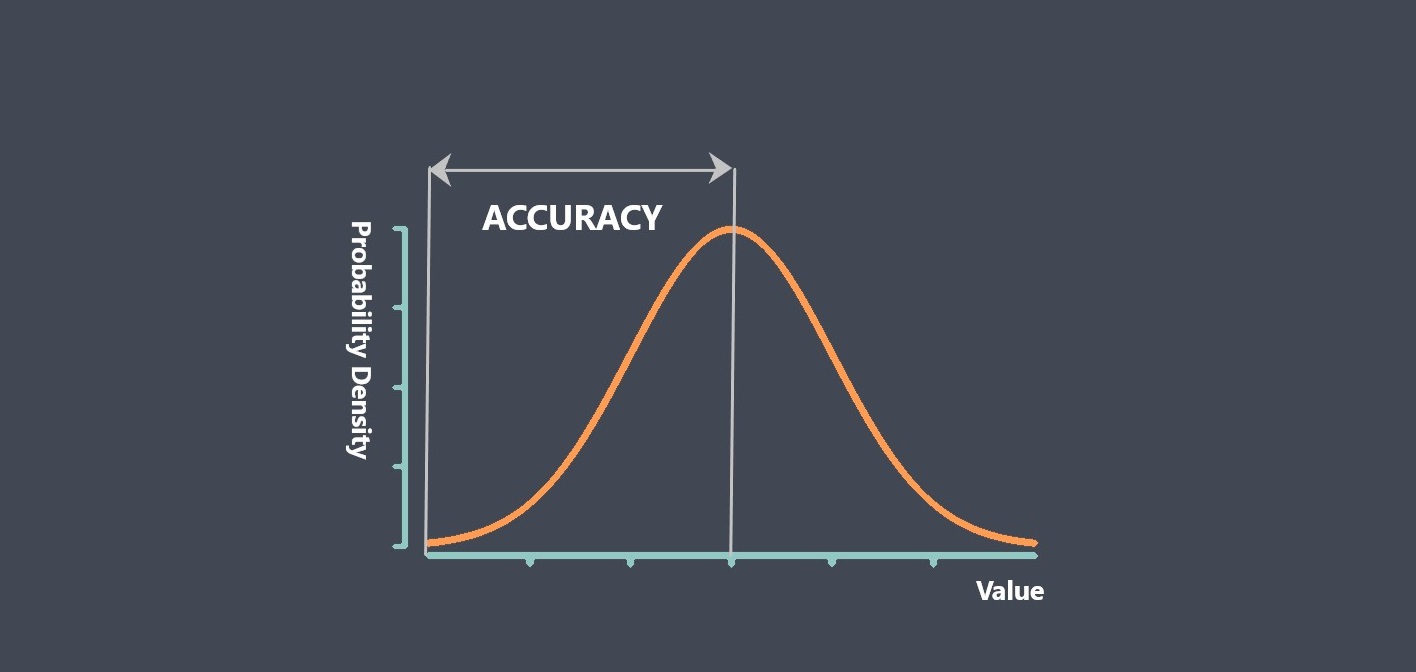

Accuracy

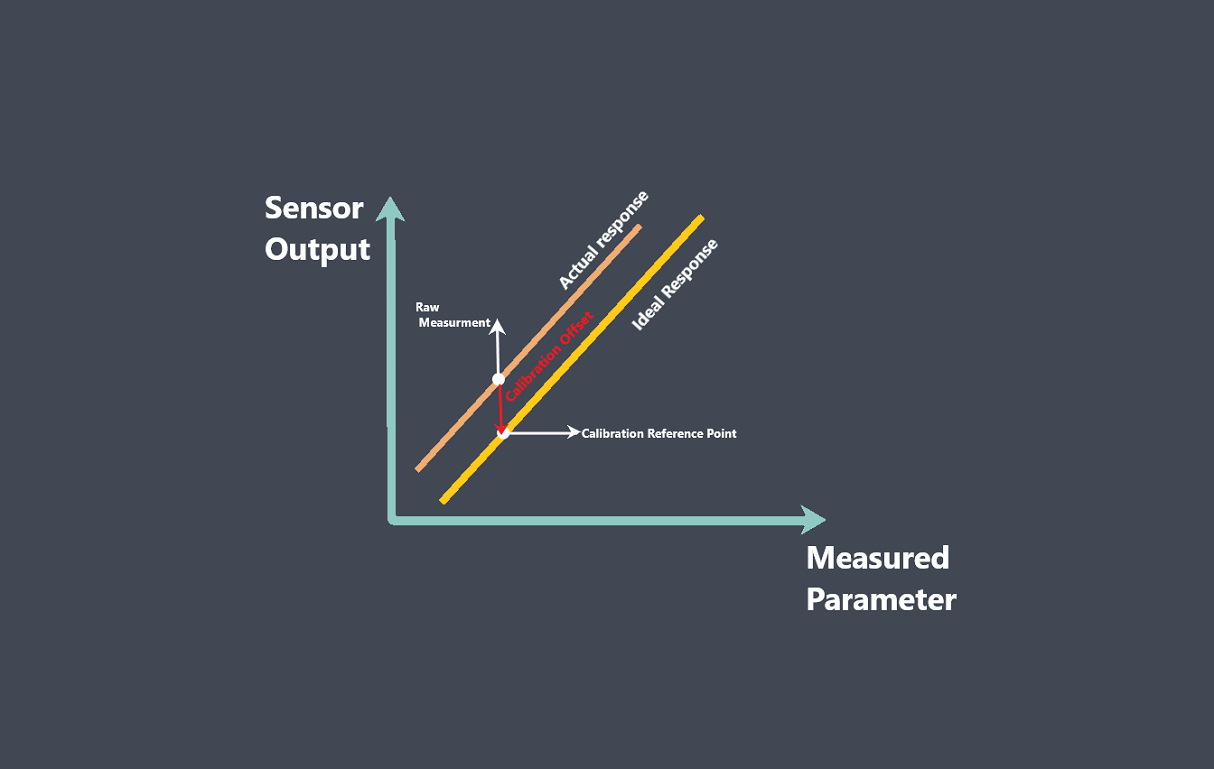

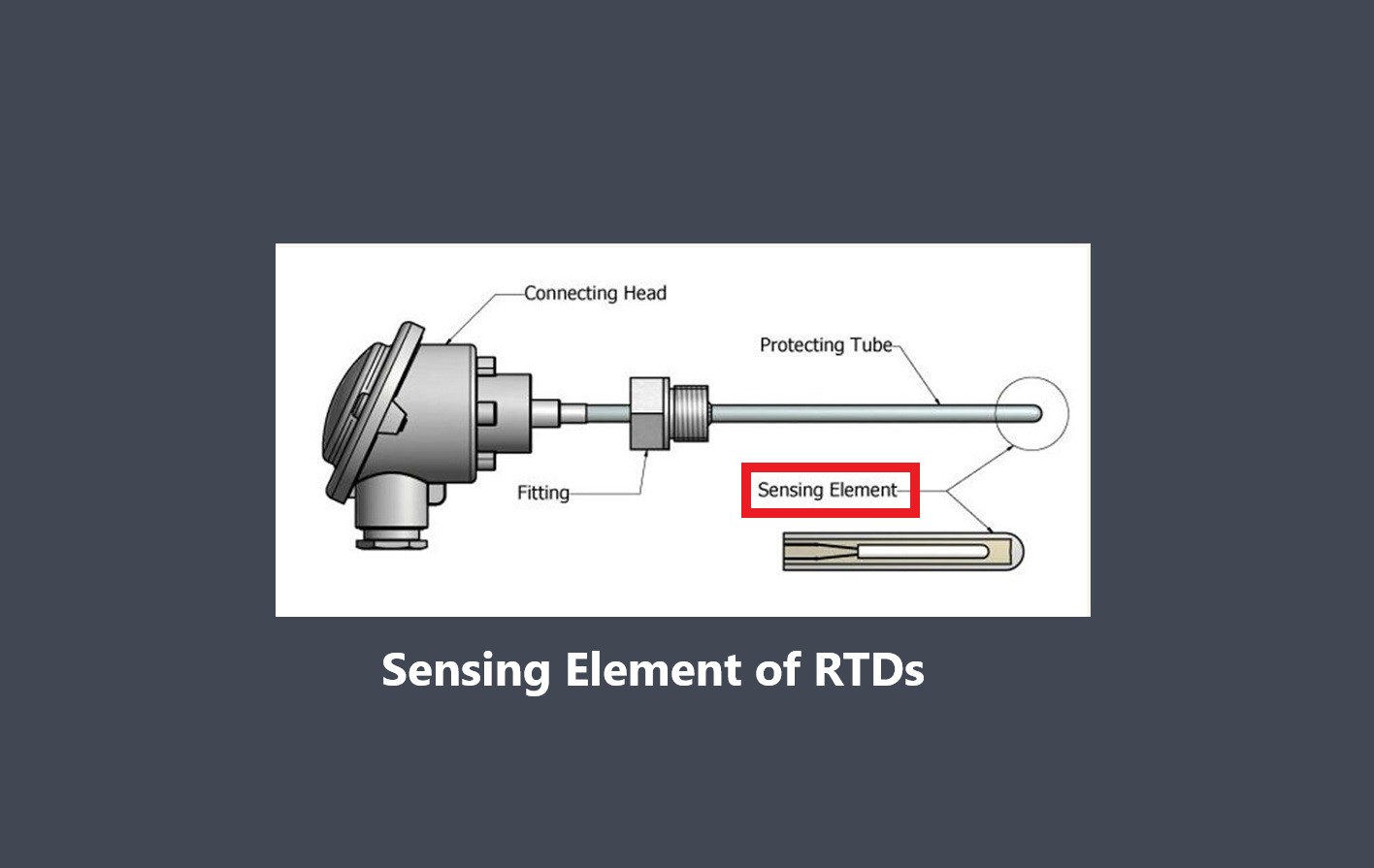

A reliable sensor should provide accurate measurements that closely correspond to the actual value or condition being measured. Accuracy is the degree of conformity between the measured value and the true value. Reliable sensors are designed and calibrated to minimize errors and provide precise measurements.

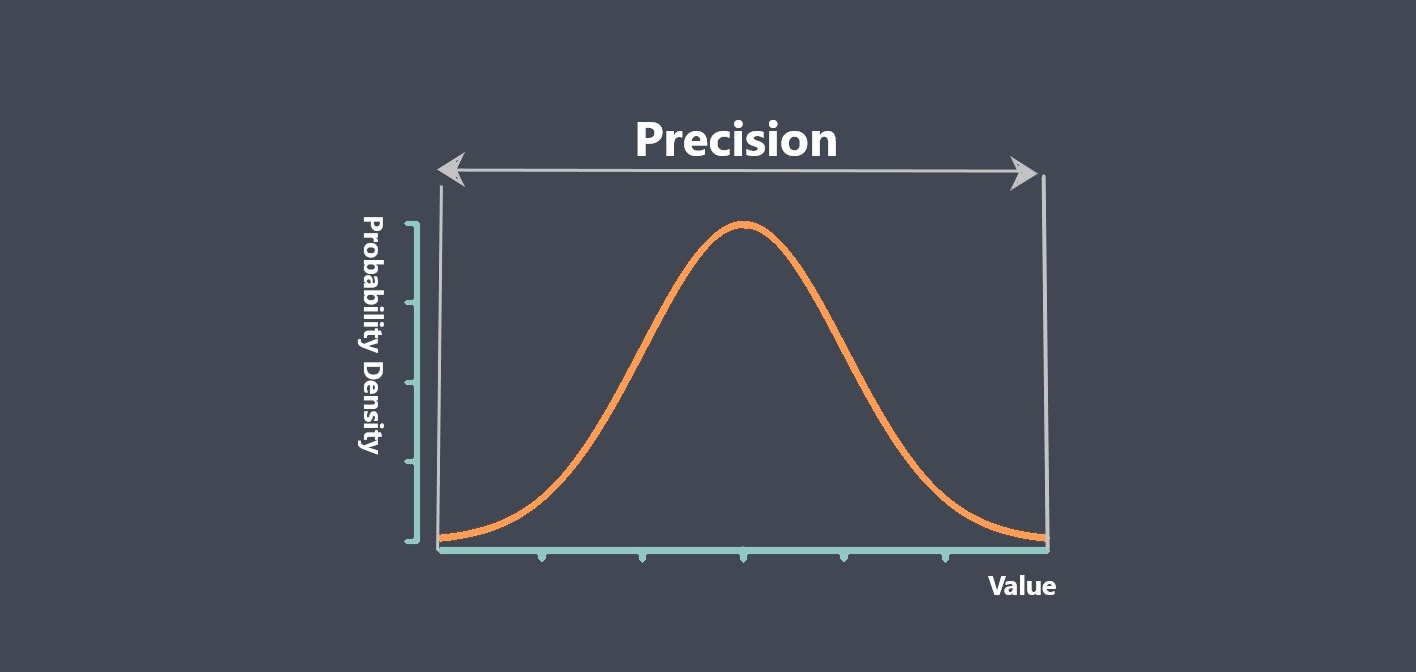

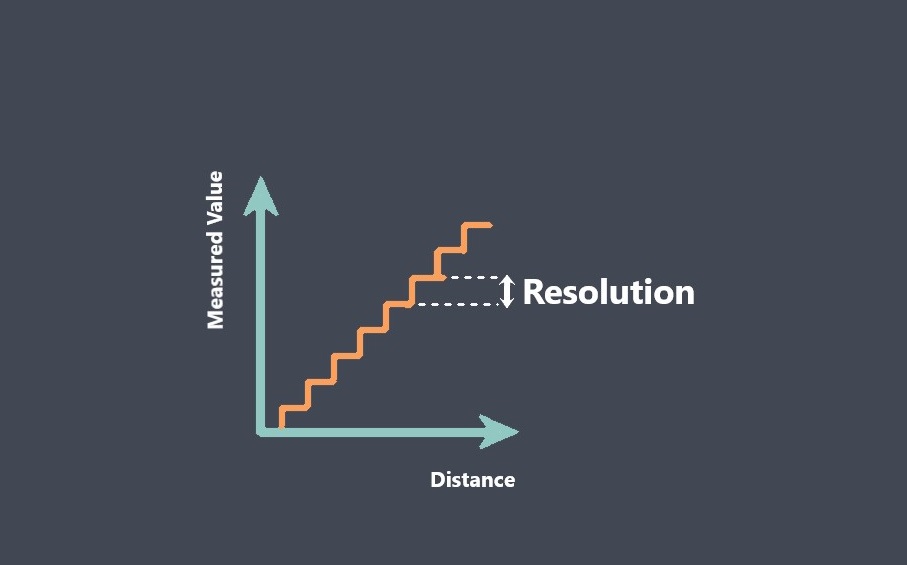

Precision

Precision refers to the repeatability and consistency of a sensor’s measurements. A reliable sensor should exhibit low variability and provide consistent results when measuring the same parameter under similar conditions. High precision indicates that the sensor can consistently reproduce the same measurement with minimal variation.

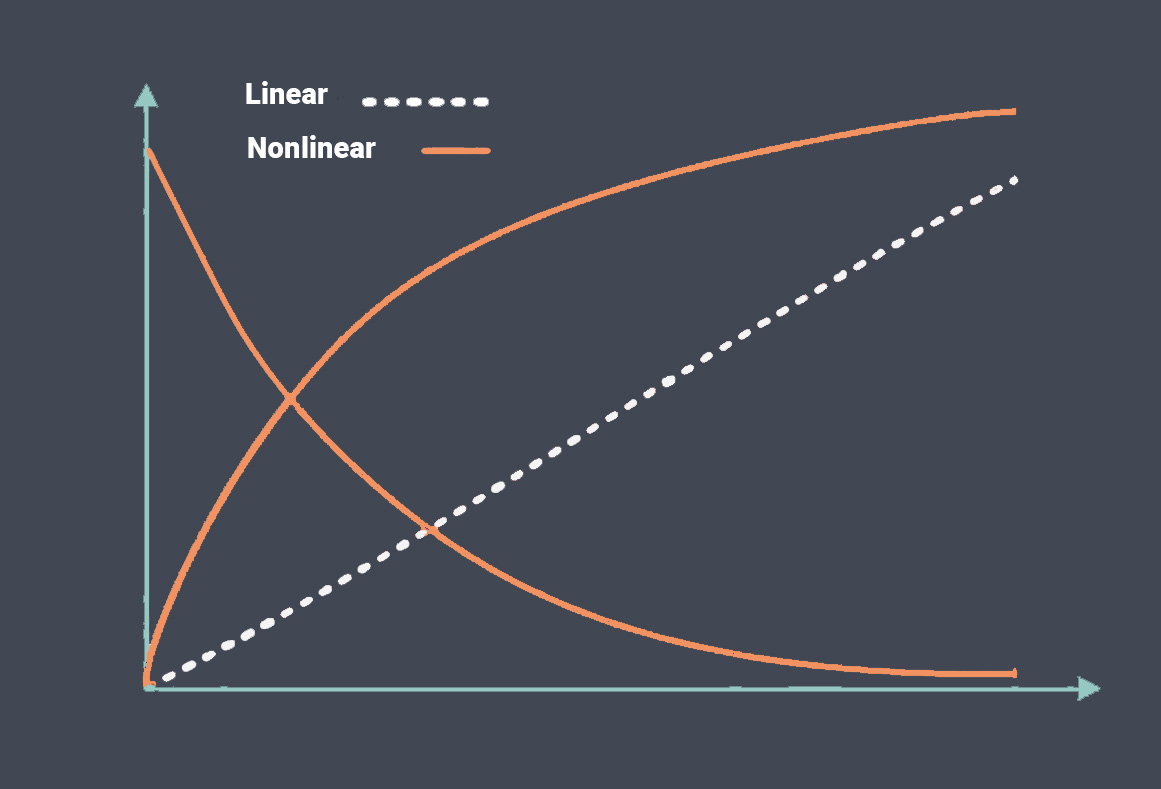

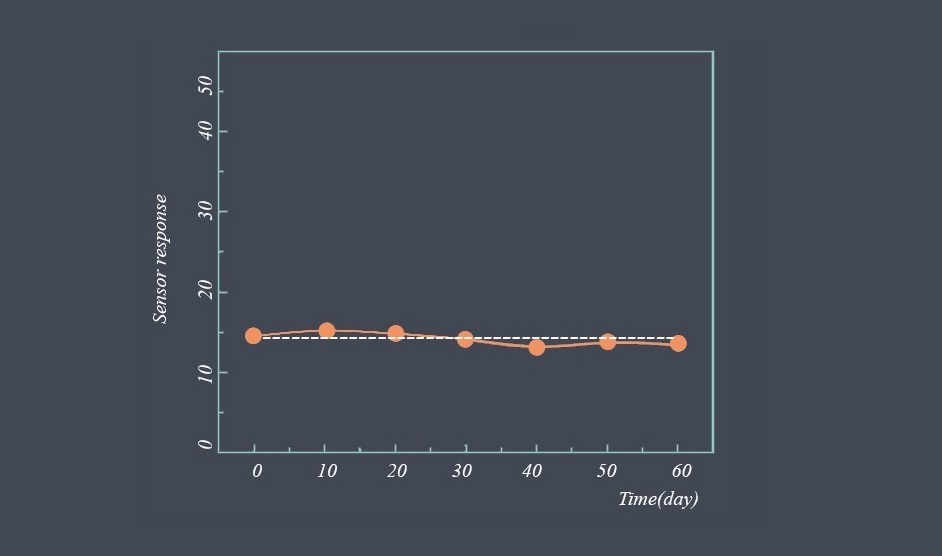

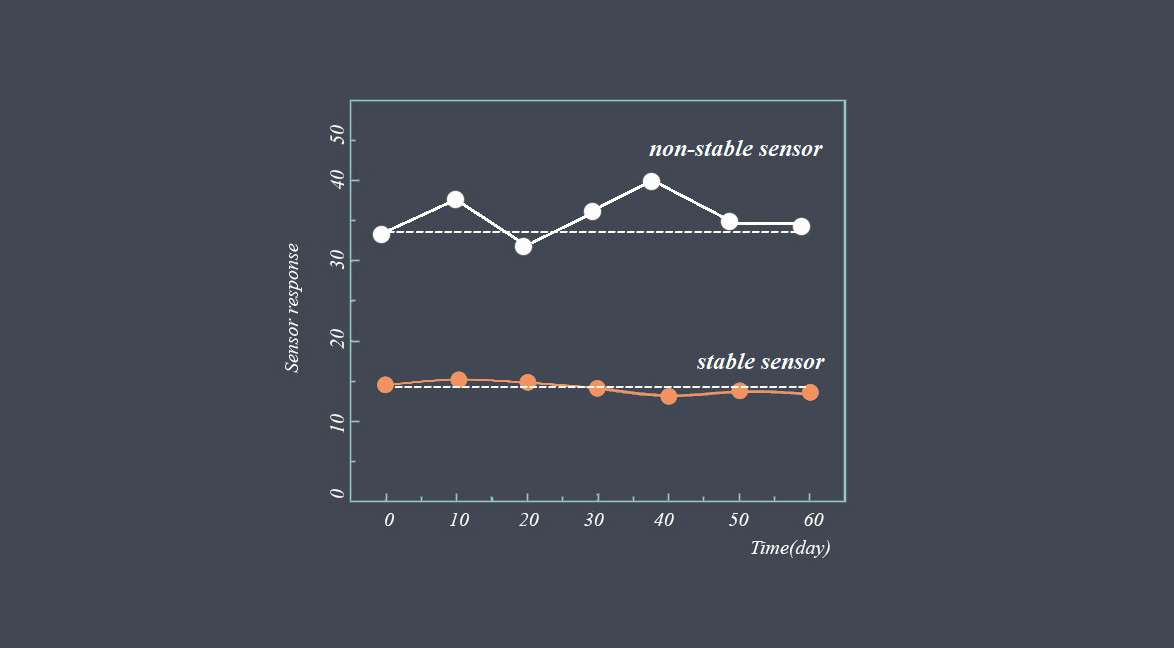

Stability

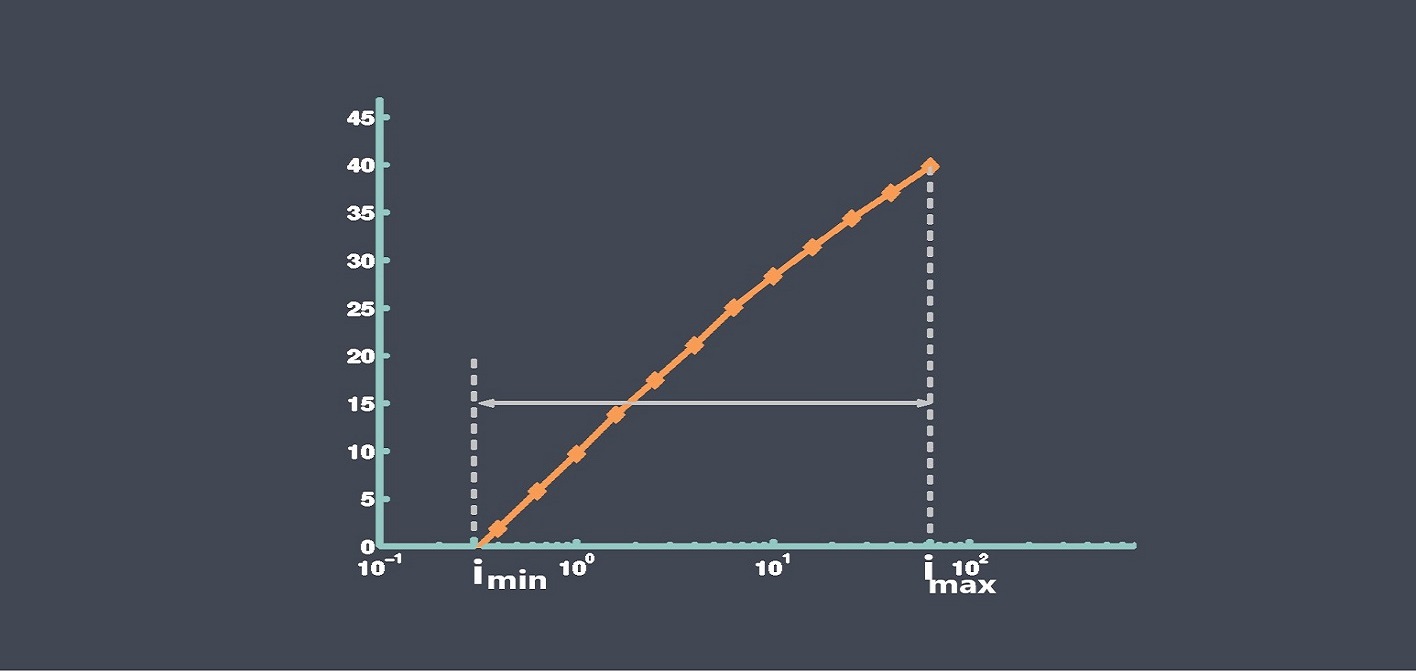

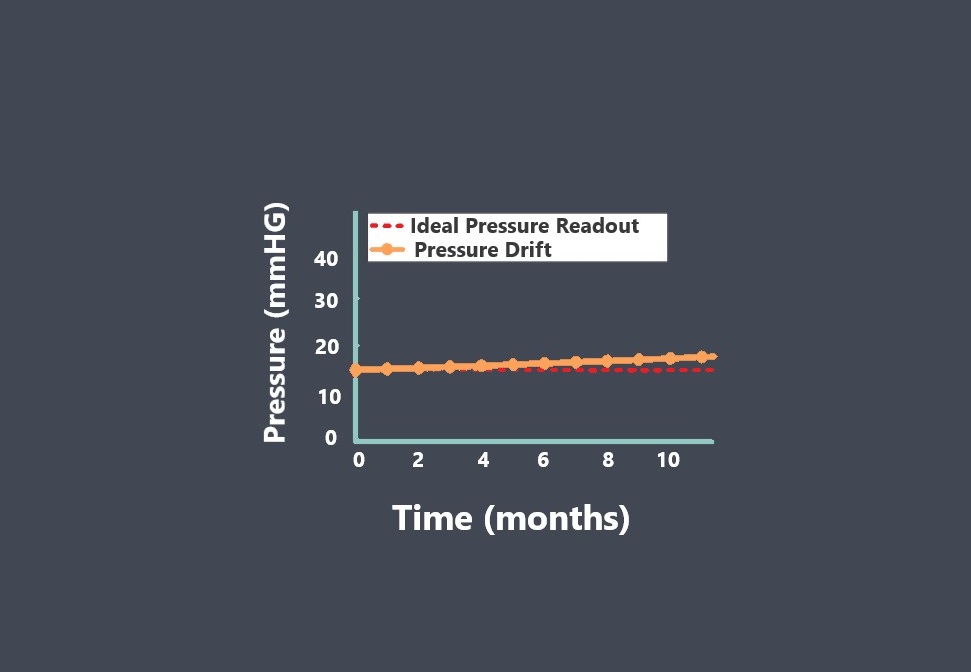

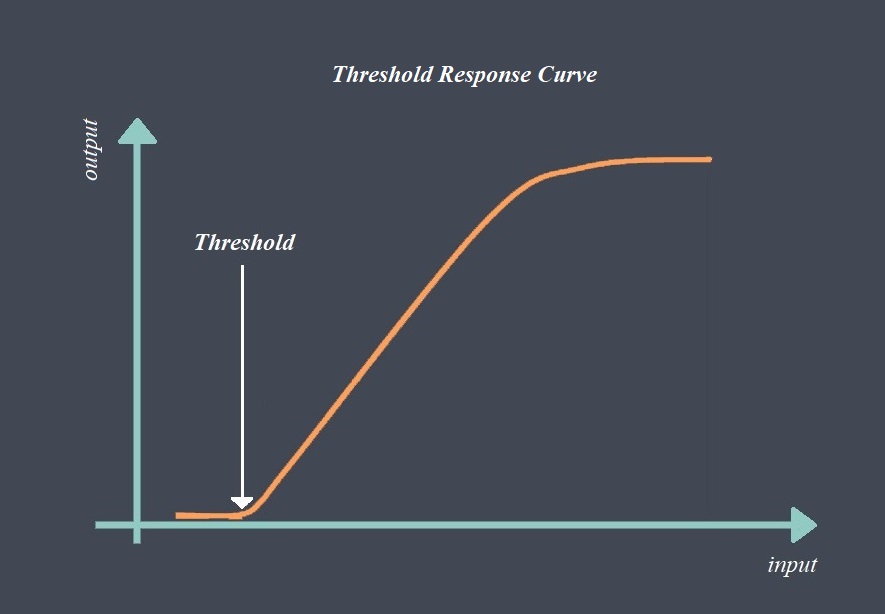

Sensor stability refers to the ability to maintain consistent performance over time. A reliable sensor should exhibit minimal drift, which is the gradual change in response or output over an extended period. Stable sensors maintain their calibration and performance characteristics over their operational lifespan.

Longevity

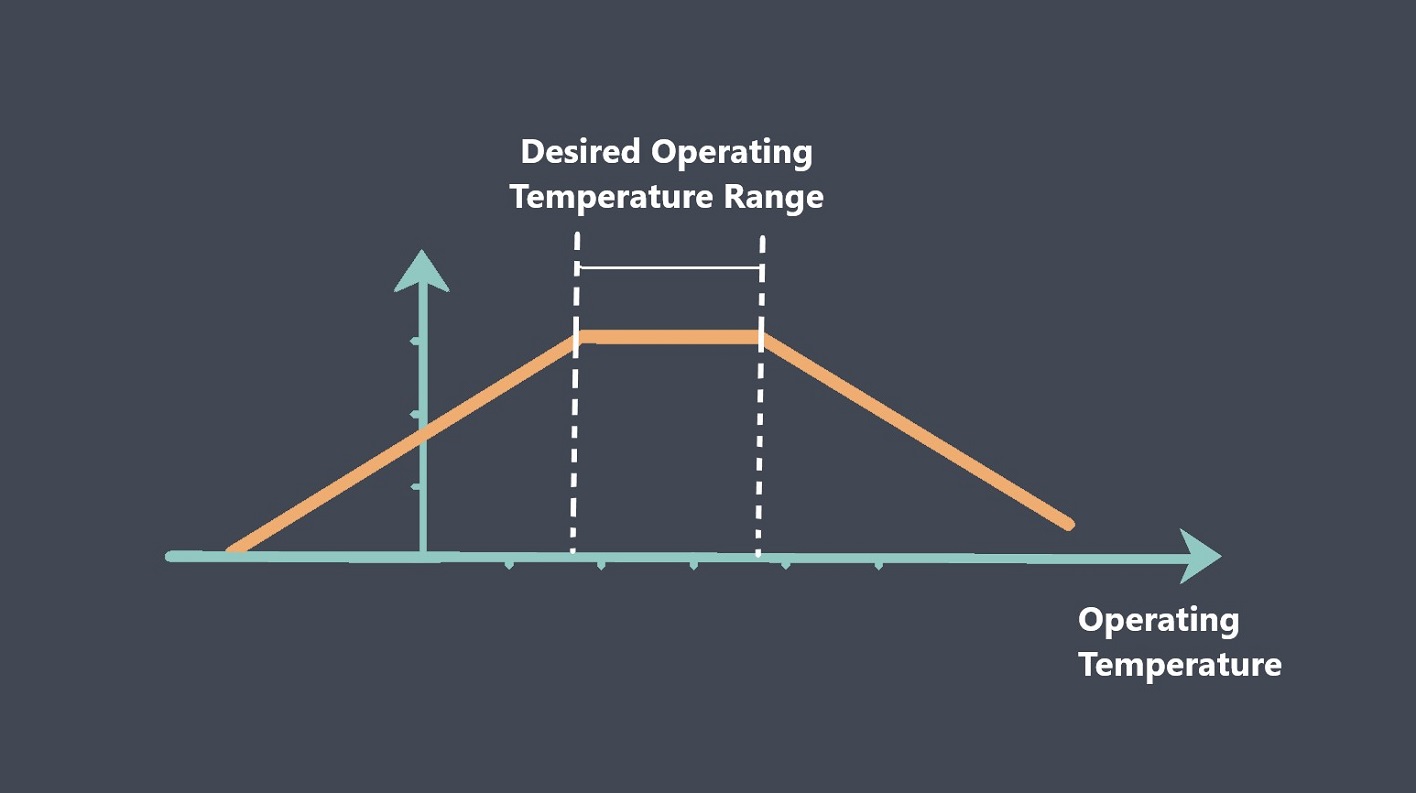

Sensor reliability also encompasses the longevity or lifespan of the sensor. A reliable sensor should have a long operational lifespan without significant degradation in performance. It should be able to withstand the expected operating conditions, environmental factors, and usage patterns without premature failure.

Robustness

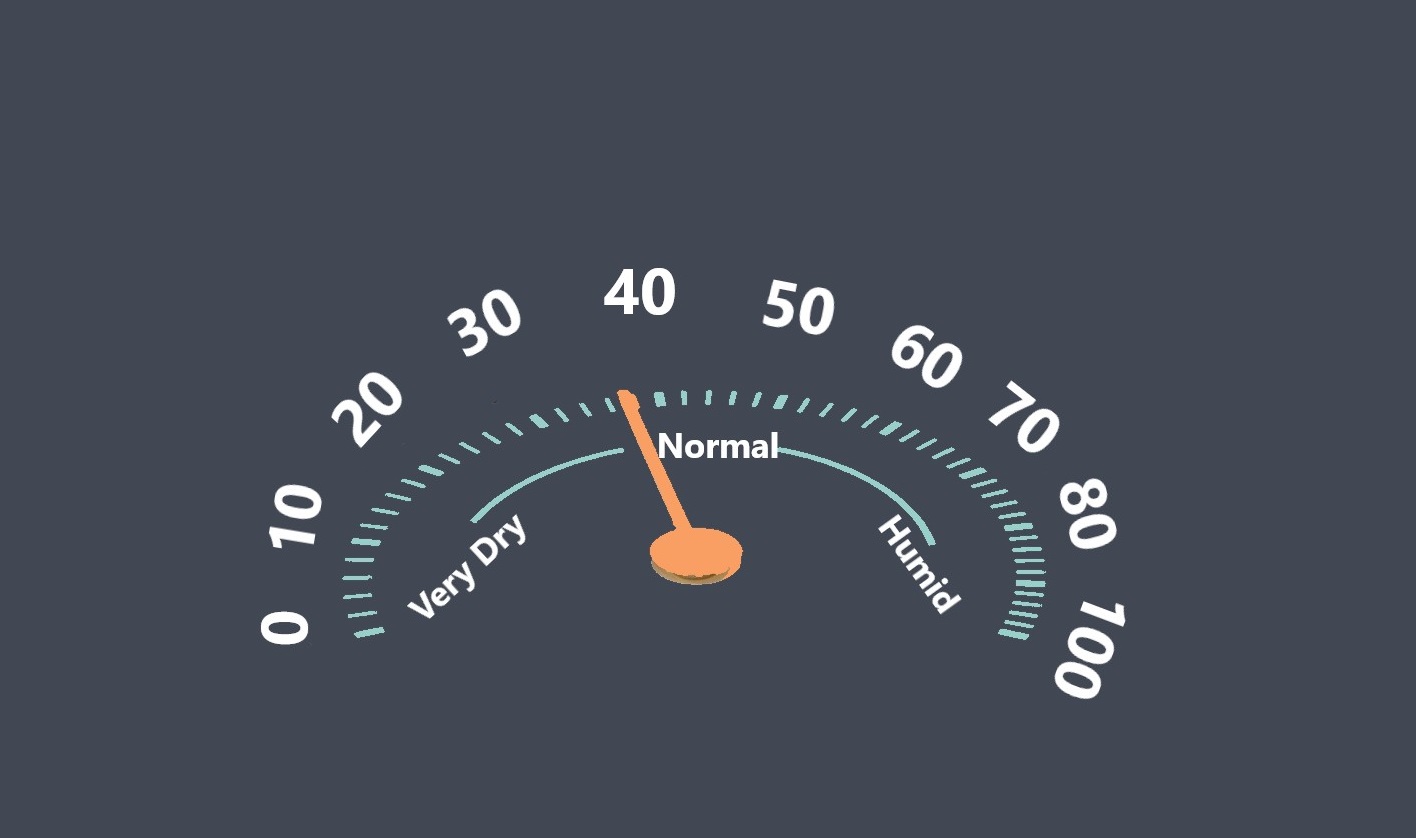

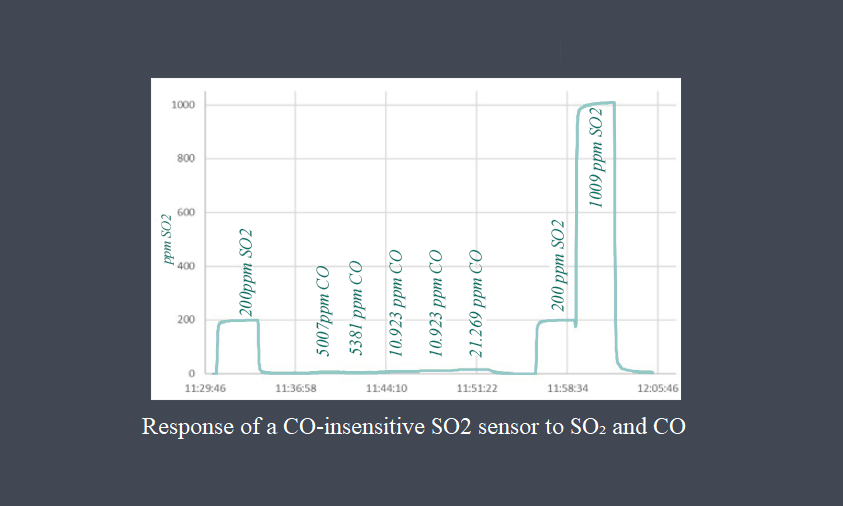

A reliable sensor should be robust enough to withstand various environmental conditions, including temperature extremes, humidity, vibration, shock, and exposure to chemicals or contaminants. It should be designed and constructed to withstand these factors without significant impact on its performance or reliability.

Consistency

Consistency refers to the ability of a sensor to provide consistent measurements across multiple units of the same model. Reliable sensors should exhibit high consistency in their performance and measurements, ensuring that different sensors of the same model produce similar results when measuring the same parameter.

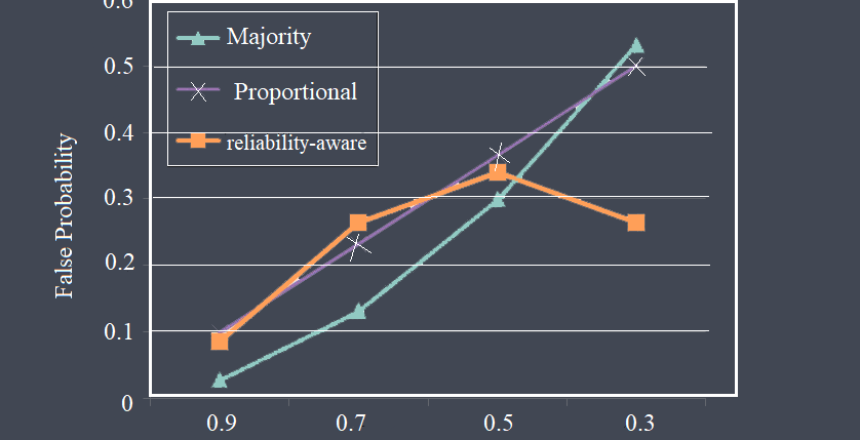

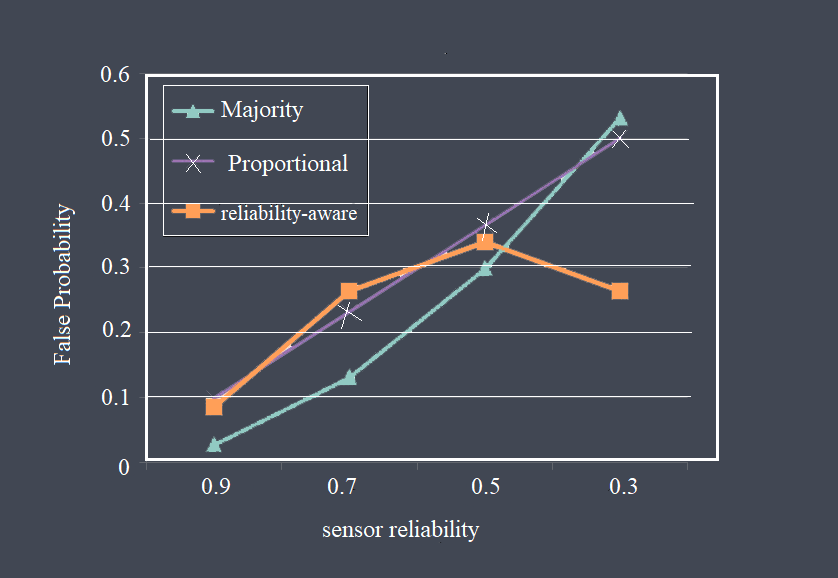

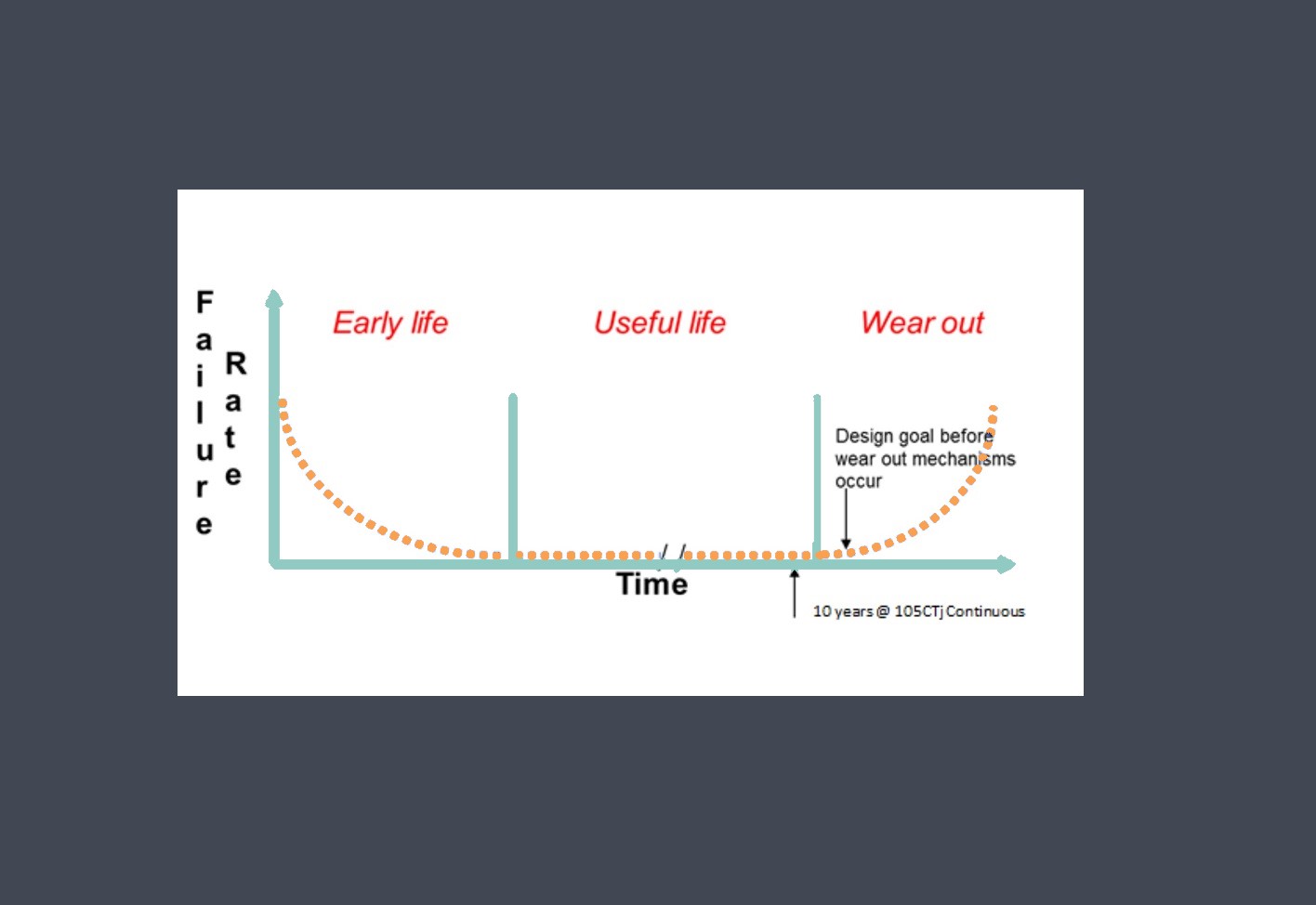

Failure Rate

Sensor reliability is often quantified in terms of failure rate, which represents the probability of a sensor failing within a given period. A reliable sensor should have a low failure rate, indicating a low probability of unexpected failures or downtime.

Mean Time Between Failures (MTBF)

MTBF is a measure of the average time between consecutive failures of a sensor. It provides an estimate of the expected operational lifespan of the sensor. A higher MTBF value suggests greater reliability and longer service life.

MTBF formula can be written as shown below:

Unreliable sensor

An unreliable sensor is one that does not consistently or accurately perform its intended function over time. It may exhibit various issues that compromise its ability to provide dependable measurements.

Here are some common characteristics or problems associated with unreliable sensors:

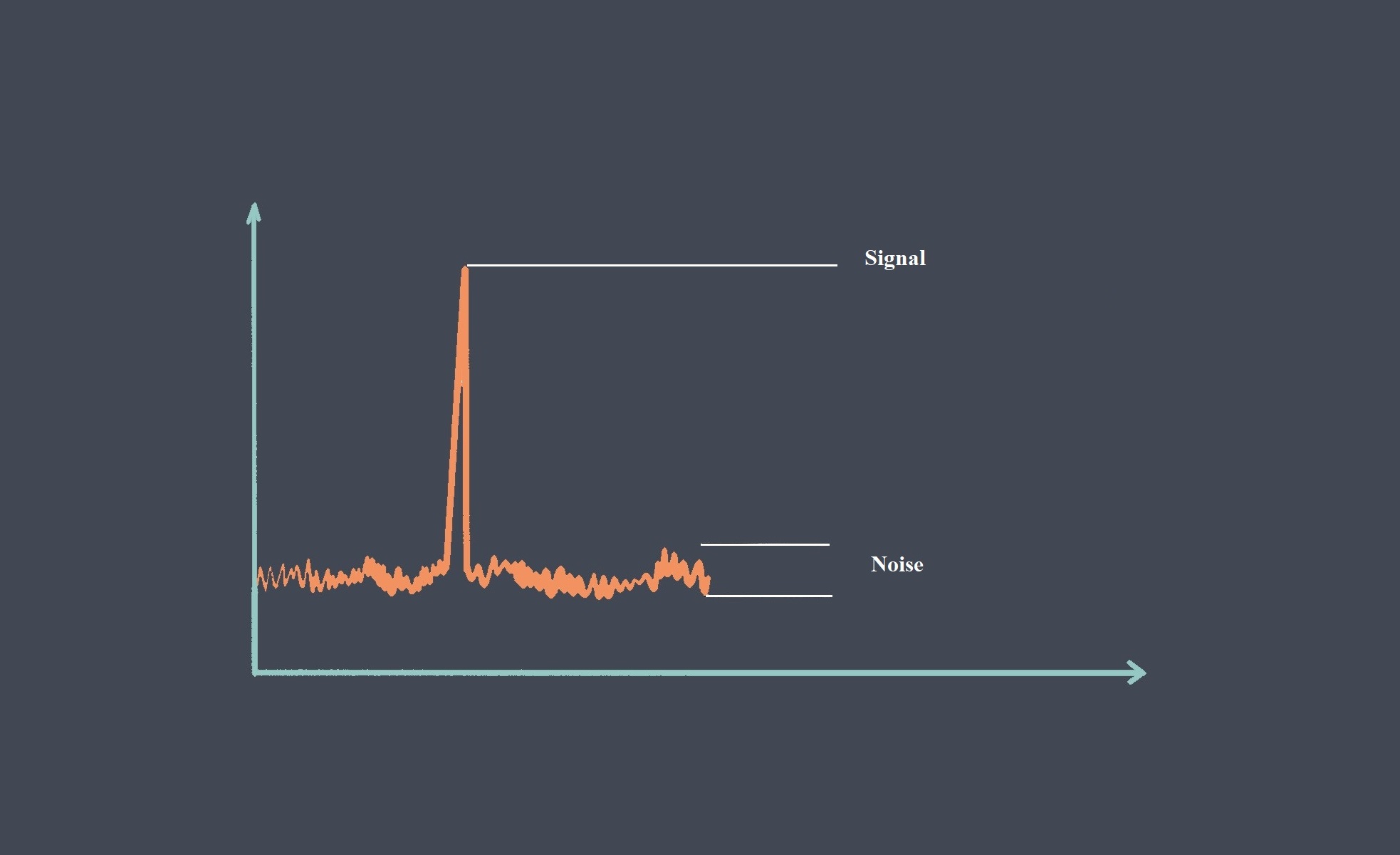

Inaccurate Measurements

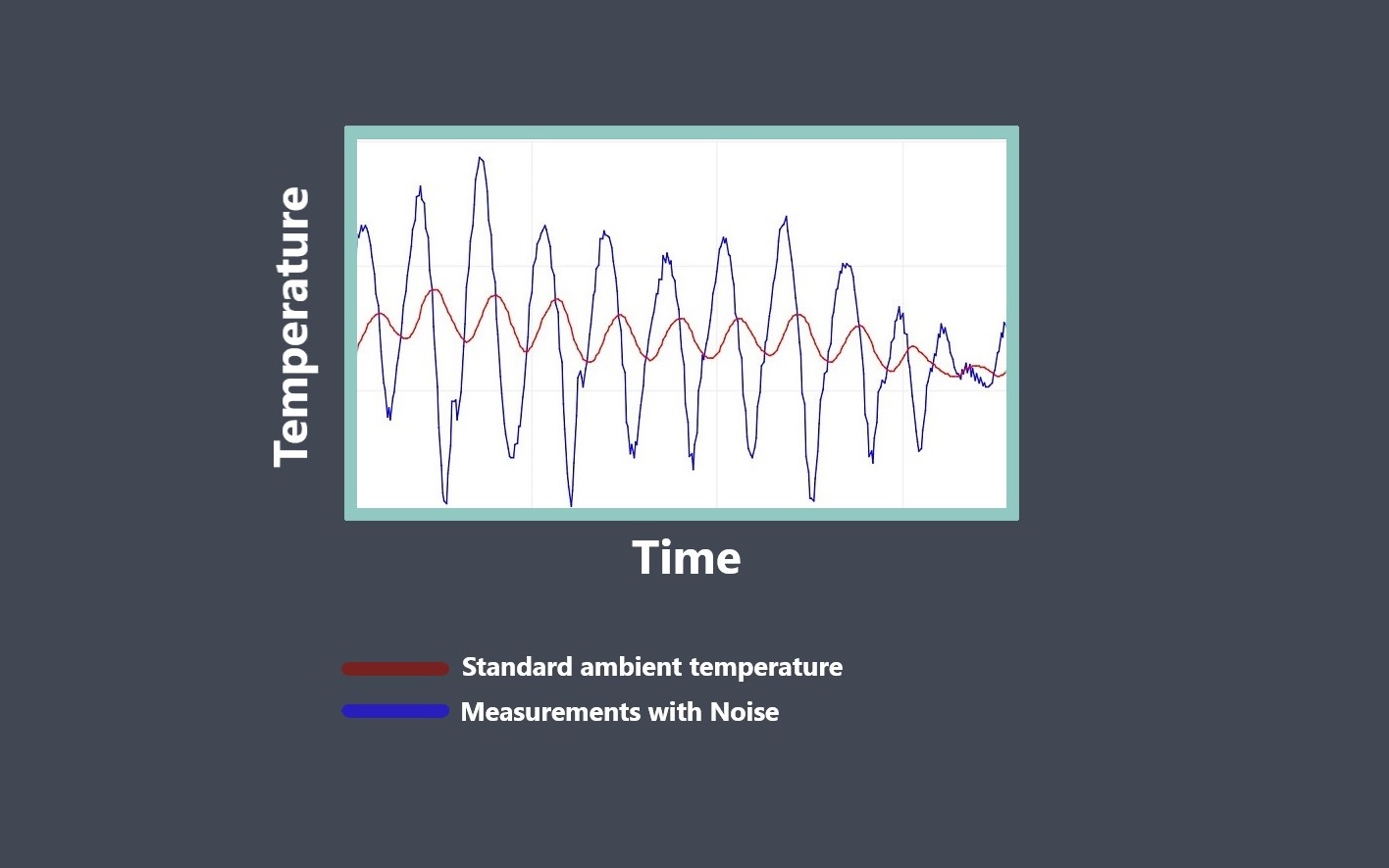

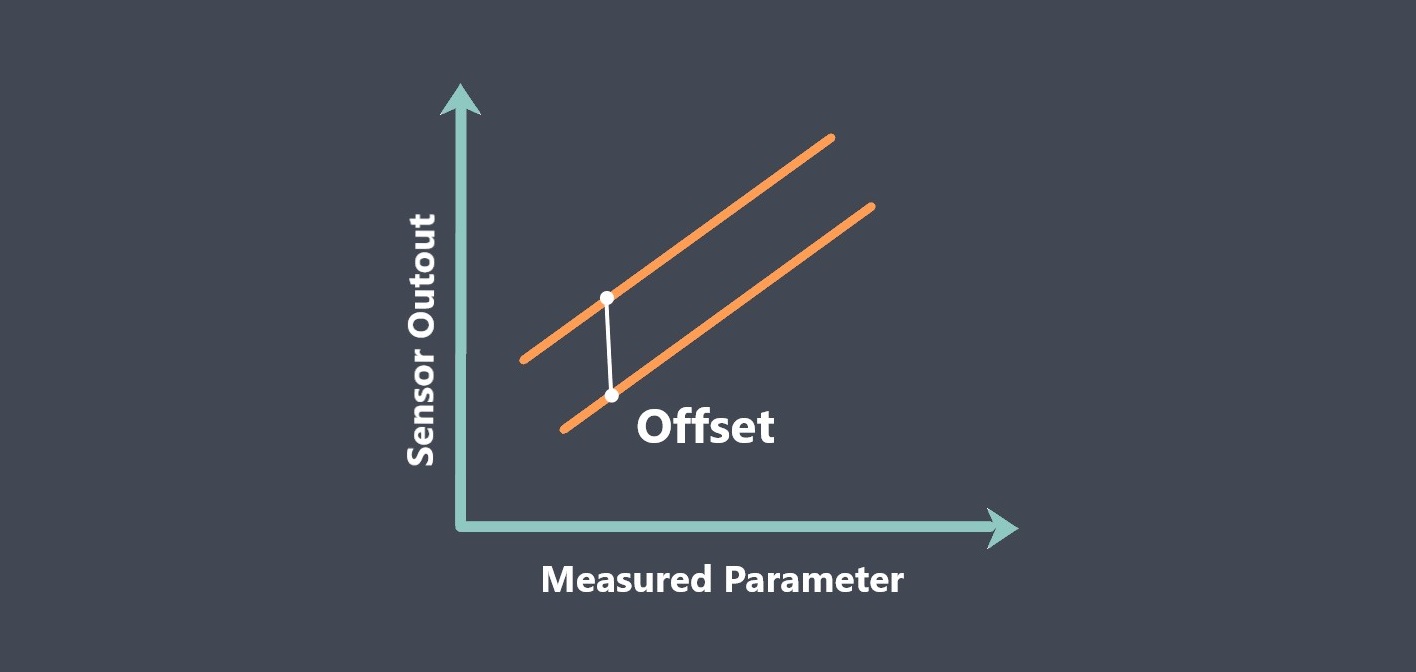

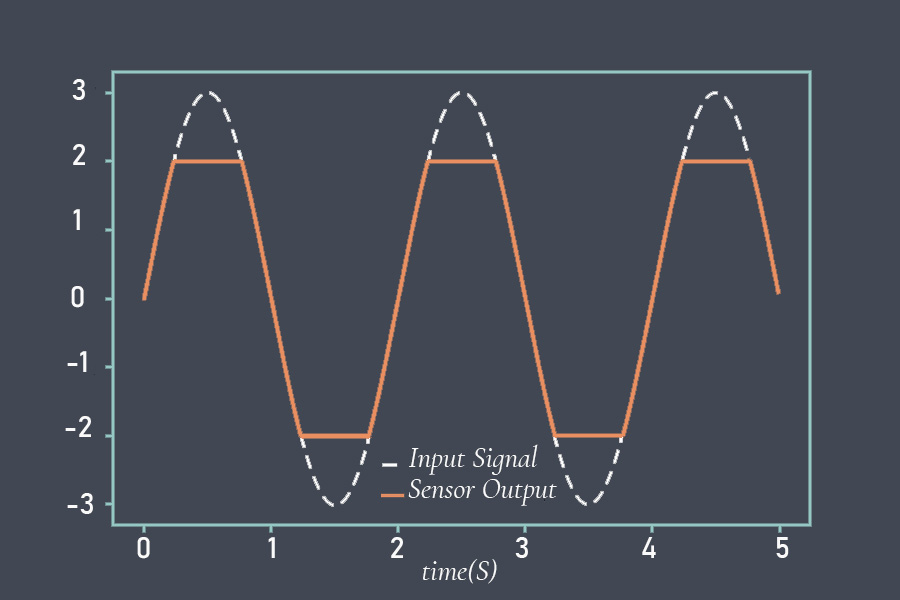

An unreliable sensor may provide measurements that deviate significantly from the true value or have inconsistent variations. It may exhibit systematic errors, random noise, or drift, leading to unreliable and erroneous data.

Inconsistent Performance

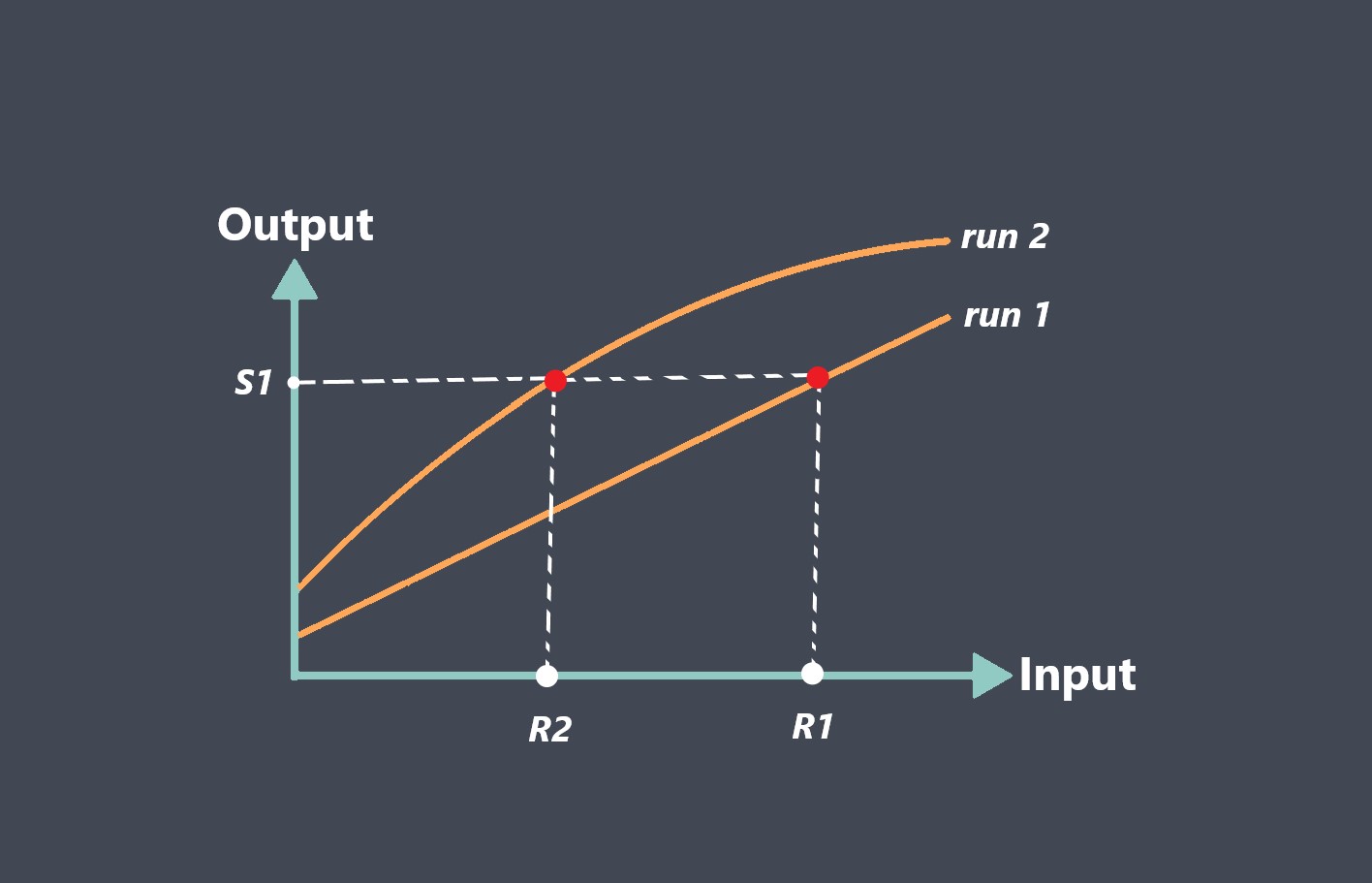

Unreliable sensors may exhibit inconsistent behavior, producing different results for the same input or under similar conditions. Inconsistency can arise from factors such as poor calibration, unstable components, or inadequate design.

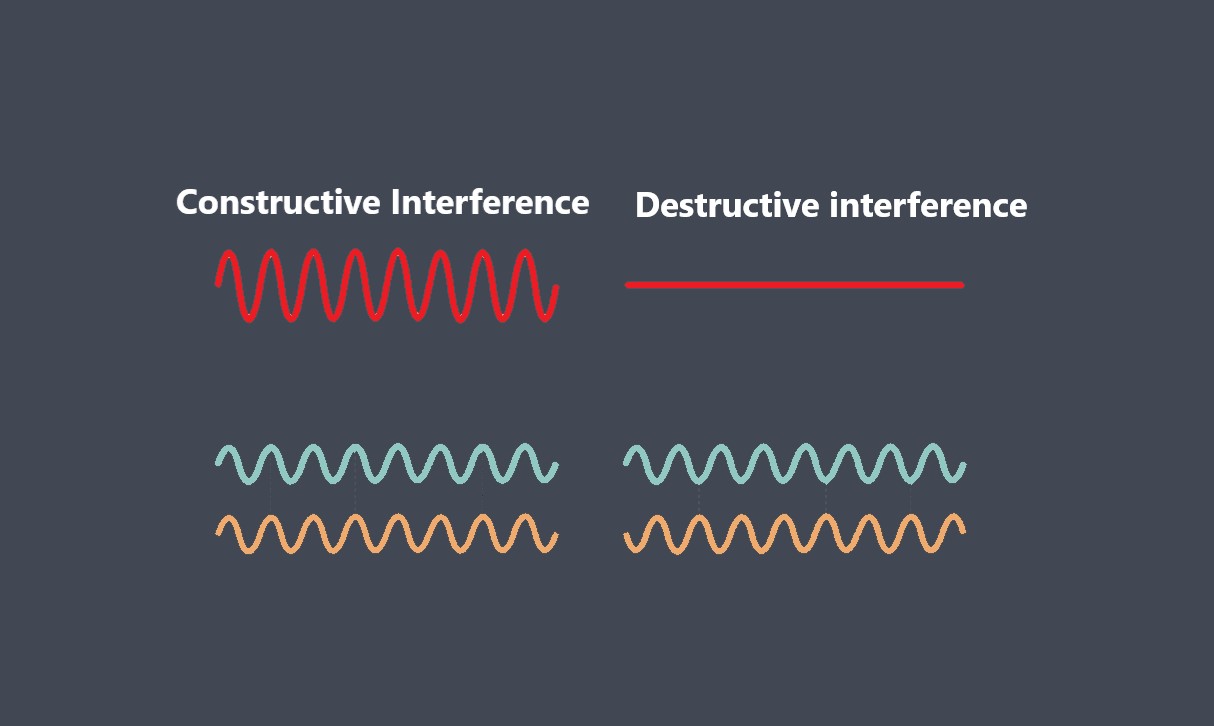

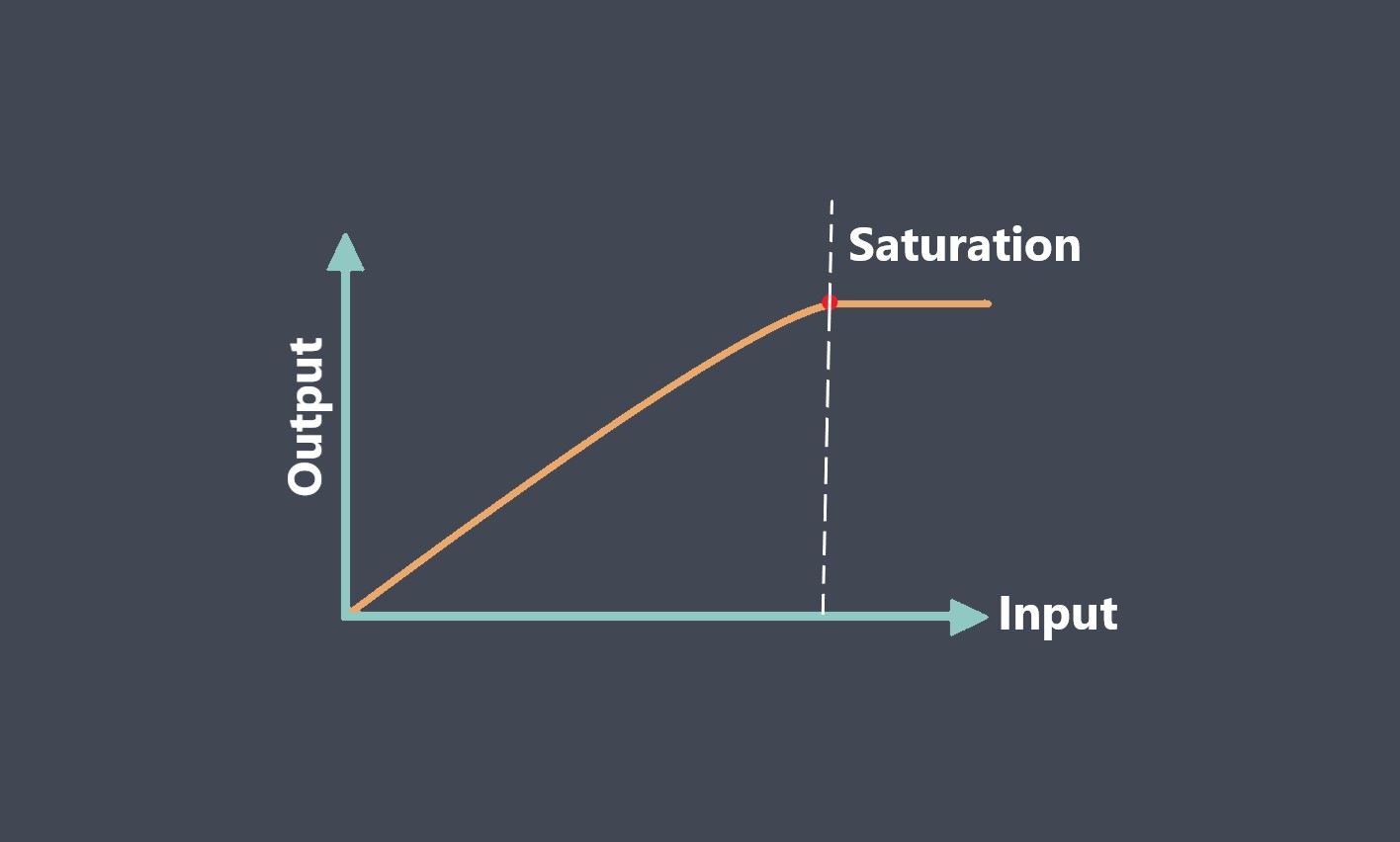

Drift and Degradation

Unreliable sensors may experience drift or degradation in their performance over time. Drift refers to the gradual change in sensor output or response, leading to inaccuracies or deviations from the initial calibration. Degradation can occur due to factors such as aging, component wear, or exposure to harsh environmental conditions.

Limited Lifespan

Unreliable sensors may have a shorter operational lifespan than expected or specified. They may fail prematurely due to design flaws, poor-quality components, or inadequate manufacturing processes. Limited lifespan can result in frequent replacements or increased maintenance requirements.

High Failure Rate

Unreliable sensors often exhibit a higher failure rate, meaning they are more likely to fail or malfunction within a given period compared to reliable sensors. Frequent failures can result in downtime, data loss, and increased costs for repairs or replacements.

Limited Reproducibility

Unreliable sensors may have poor reproducibility, meaning that different units of the same sensor model may produce inconsistent measurements. Lack of reproducibility can lead to difficulties in comparing data or implementing sensor networks.

Dealing with unreliable sensors requires identifying the underlying causes and taking appropriate actions. This may involve recalibration, maintenance, component replacement, or upgrading to more reliable sensor models.