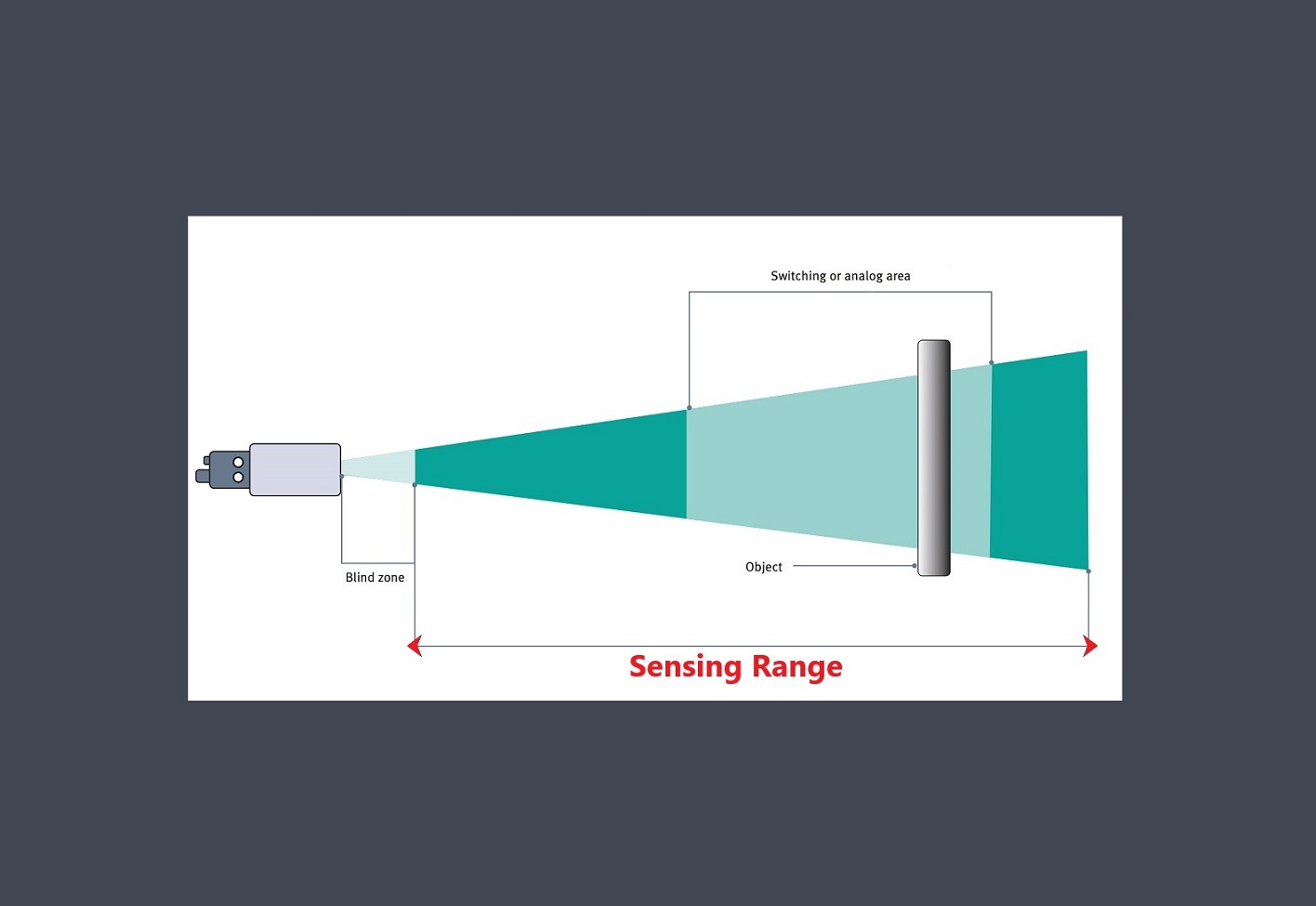

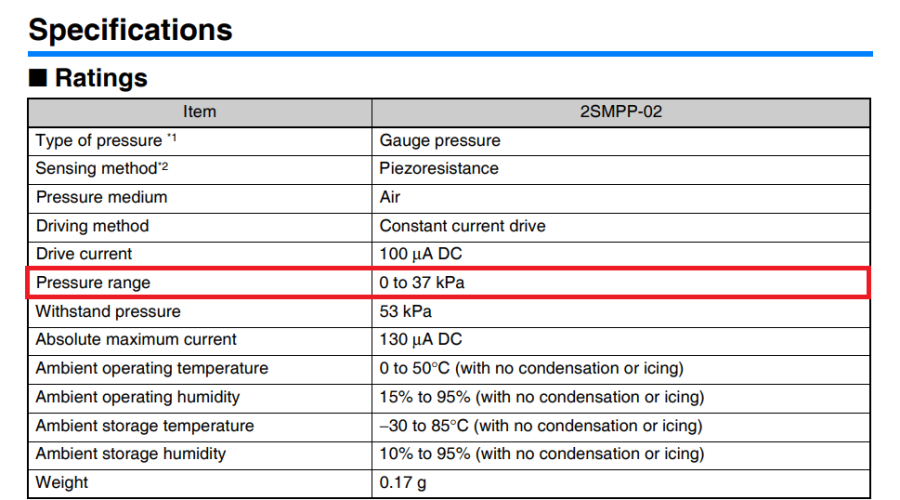

The pressure range is an essential parameter for sensors that measure or respond to variations in pressure. It defines the minimum and maximum pressure values within which a sensor can operate reliably and provide accurate measurements. Pressure sensors are widely used in applications such as industrial processes, automotive systems, and environmental monitoring.

The operating pressure range of a sensor can vary depending on its type and application. Sensors are designed to measure and detect various physical quantities such as pressure, temperature, humidity, and more. Each type of sensor has its own specified operating pressure range, which indicates the minimum and maximum pressures at which it can accurately function.

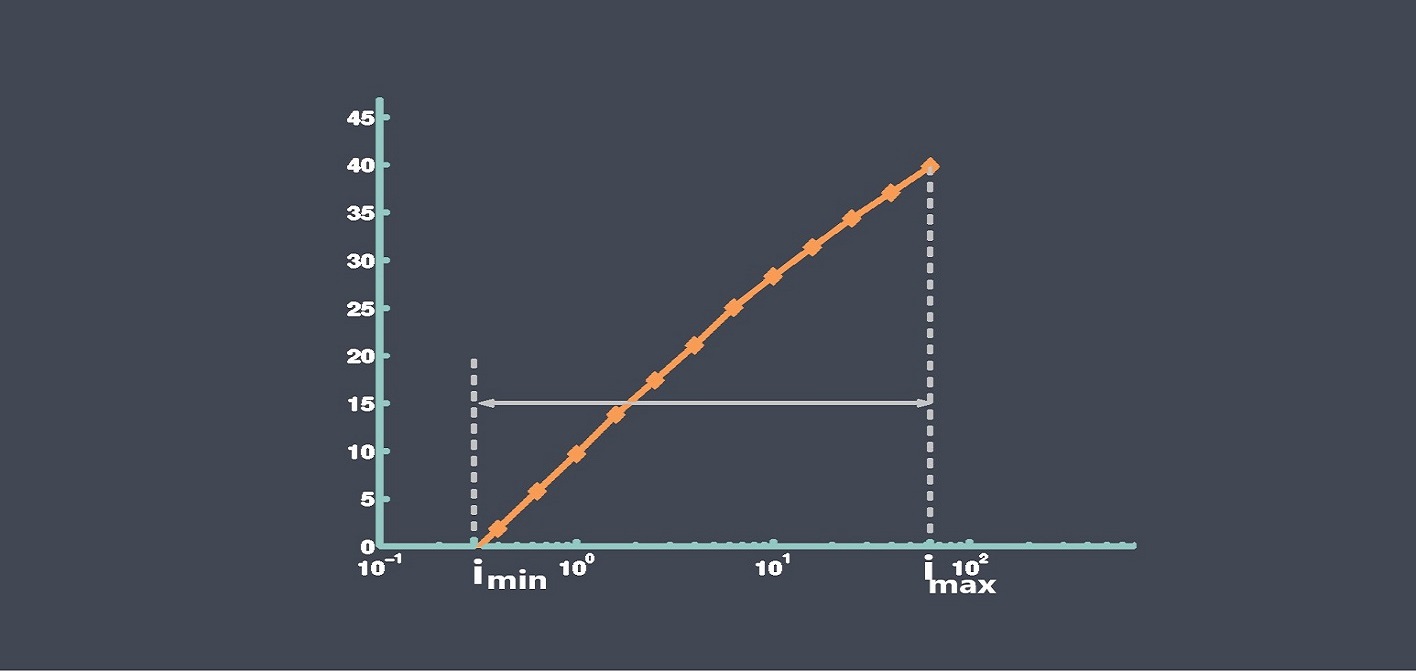

For example, pressure sensors used in industrial applications typically have a wide operating pressure range to accommodate high-pressure environments. They may be capable of measuring pressures ranging from a few millibars (mbar) up to several thousand bars (bar) or even higher.

On the other hand, pressure sensors used in low-pressure applications, such as medical devices or HVAC systems, might have a narrower operating range. These sensors may be designed to measure pressures from a fraction of a bar (e.g., 0.1 bar) up to a few tens or hundreds of bars.

Pressure operating range main parameters

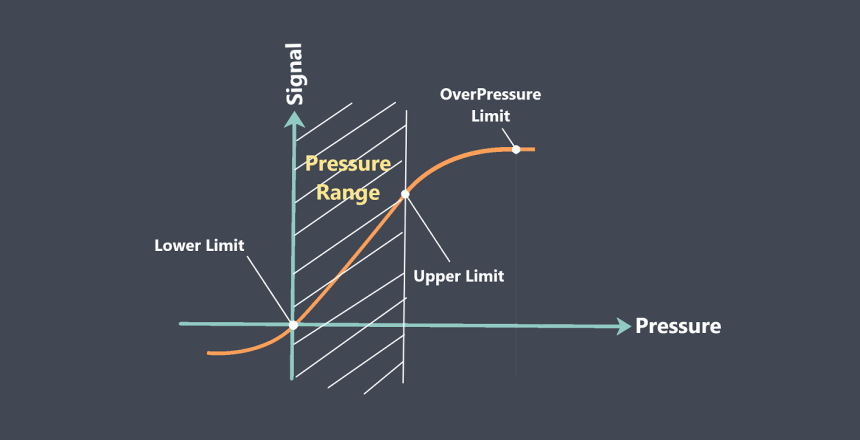

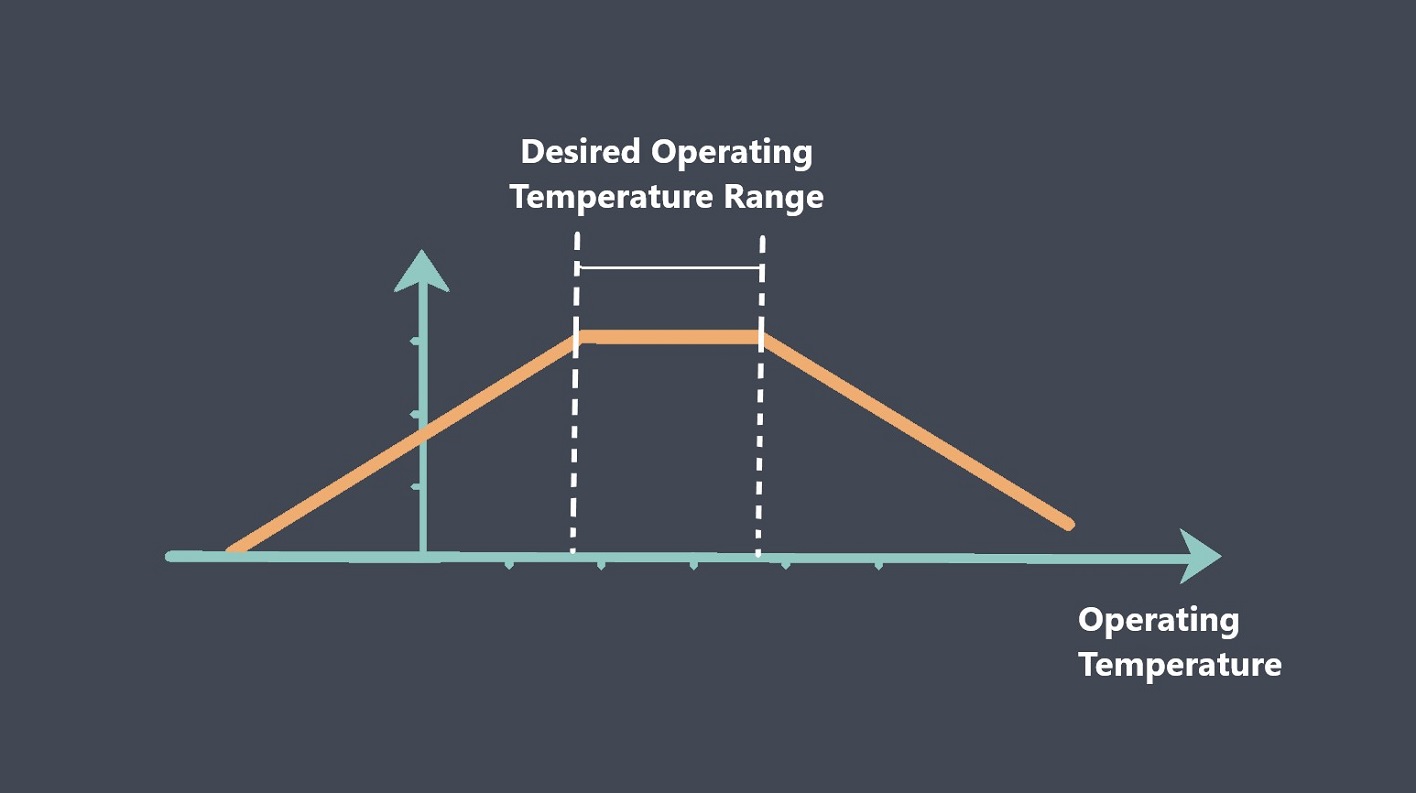

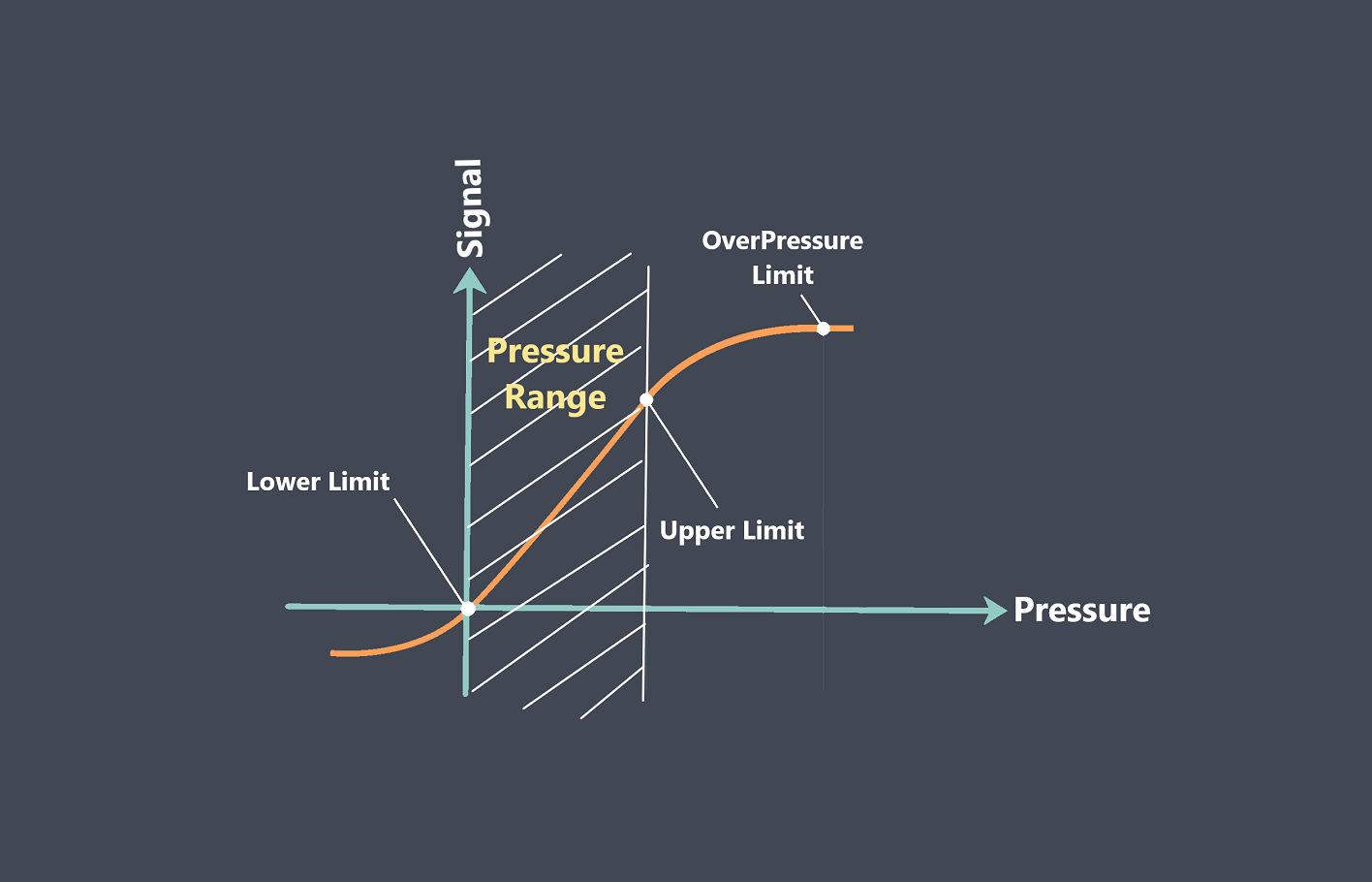

The pressure operating range refers to the acceptable limit within which a system or device can function properly and safely. It typically includes two values: “the minimum and maximum pressure levels” that the system can withstand or operate within. The range is usually specified in units of pressure such as Pascals (Pa), pounds per square inch (psi), or bar.

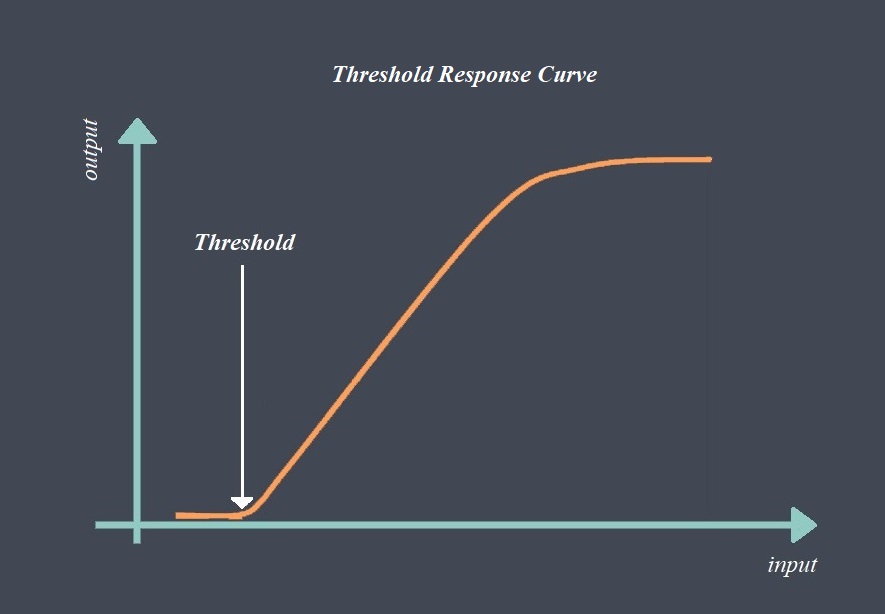

- Minimum Pressure: This parameter defines the lower limit of pressure below which the system may not function optimally or fail to operate. It is crucial to ensure that the pressure stays above this value to maintain proper functionality.

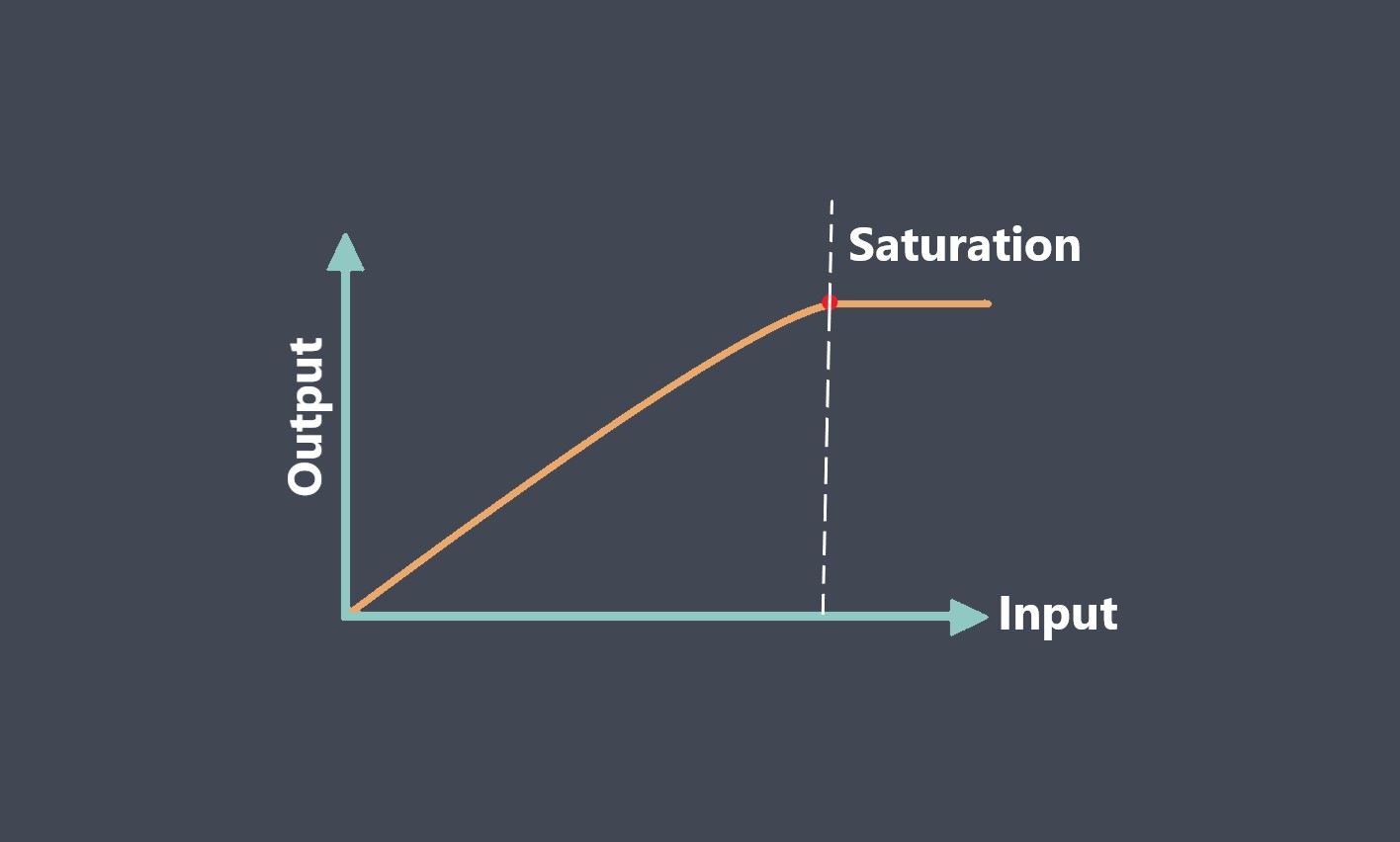

2. Maximum Pressure: This parameter specifies the upper limit of pressure beyond which the system may get damaged, malfunction, or become unsafe. It is essential to prevent pressure from exceeding this value to avoid catastrophic failures or hazards.

How does pressure affect sensor measurements?

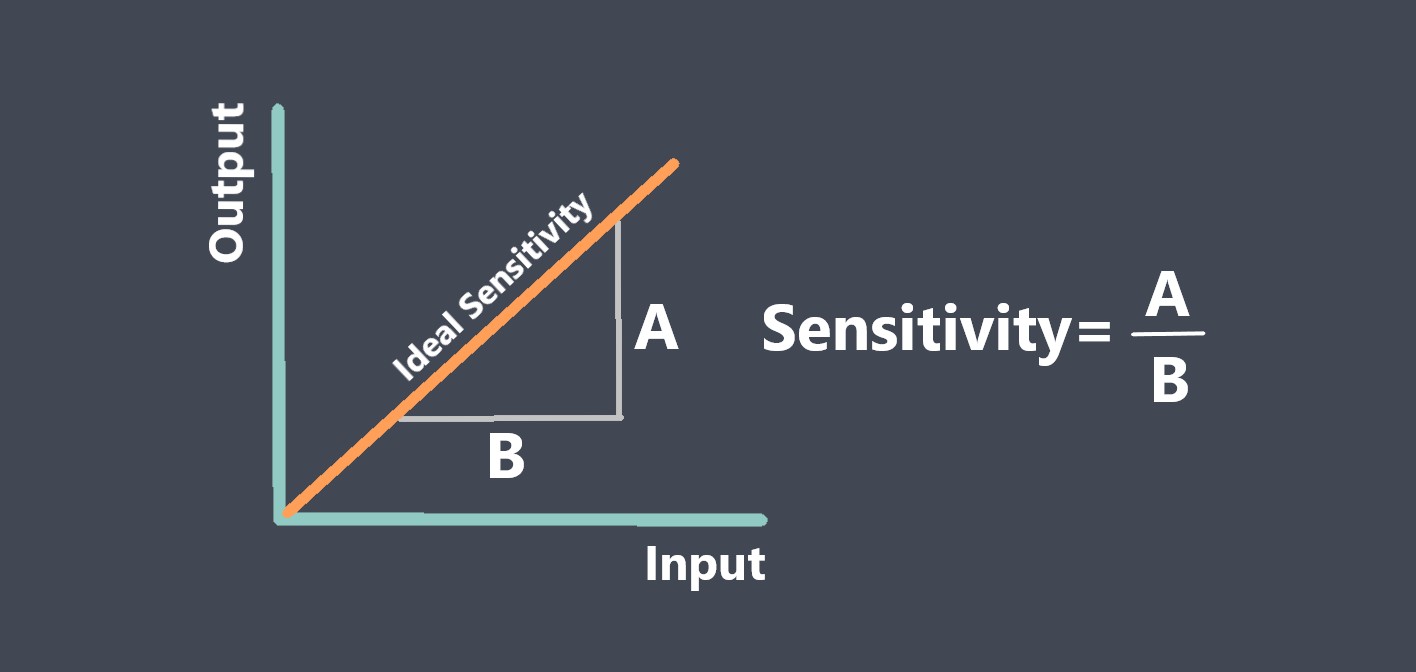

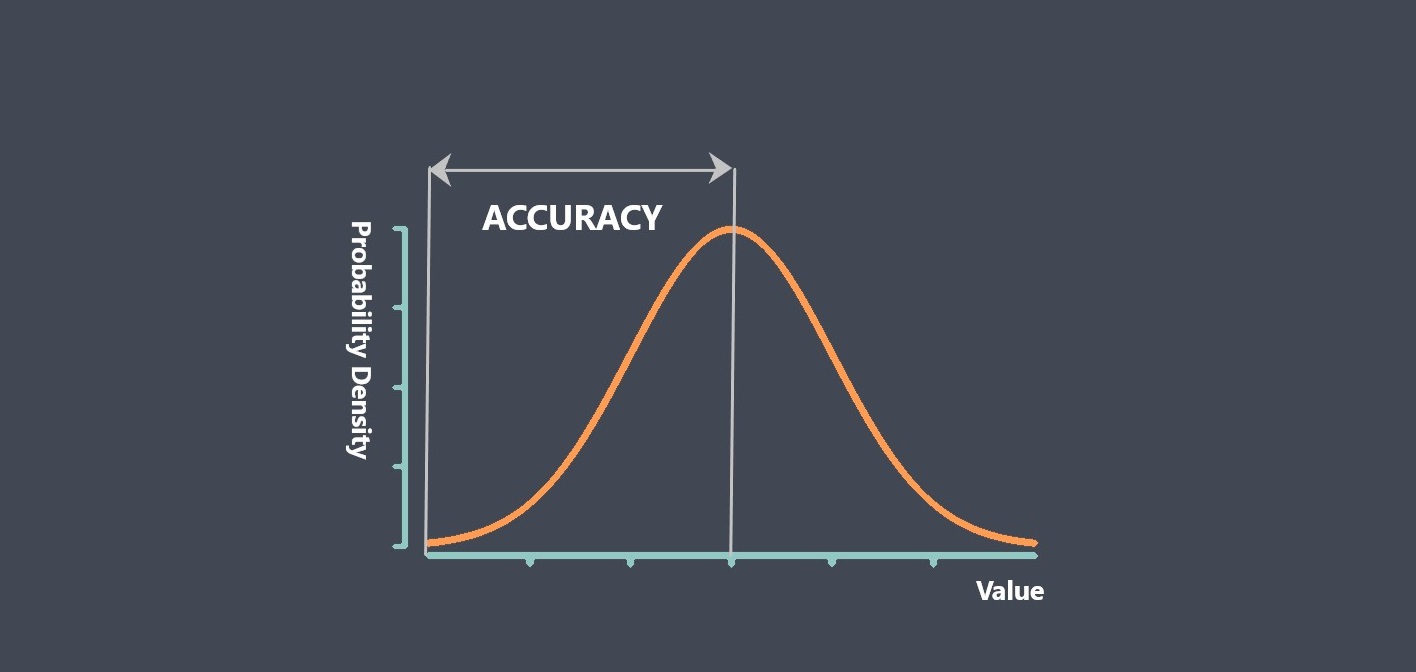

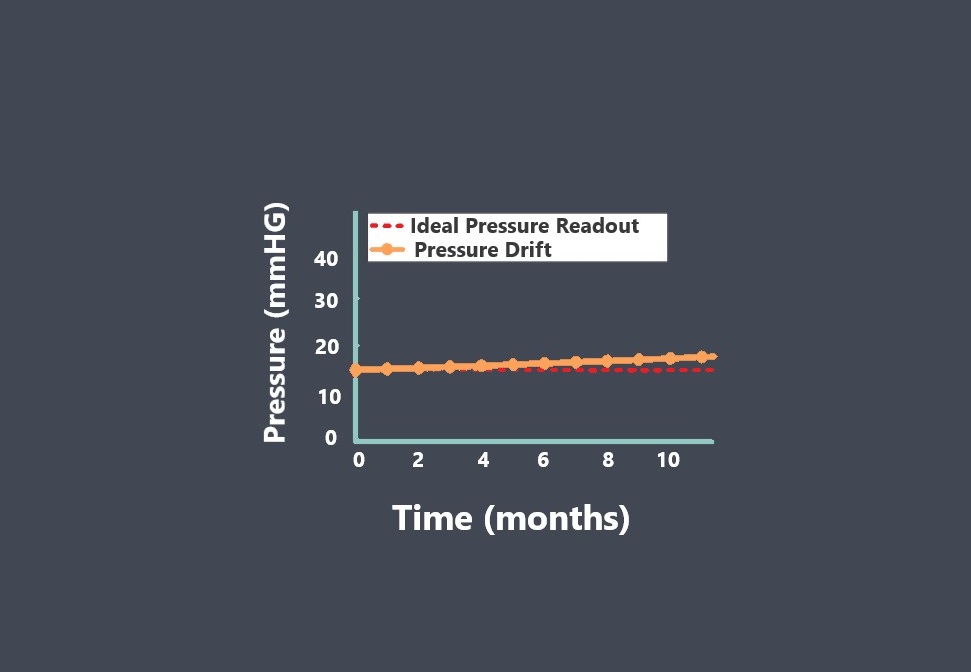

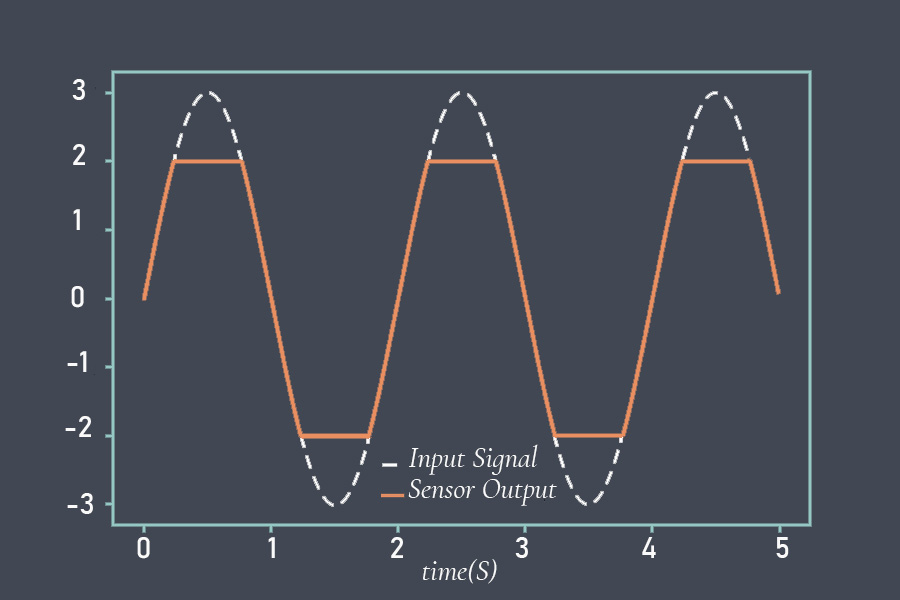

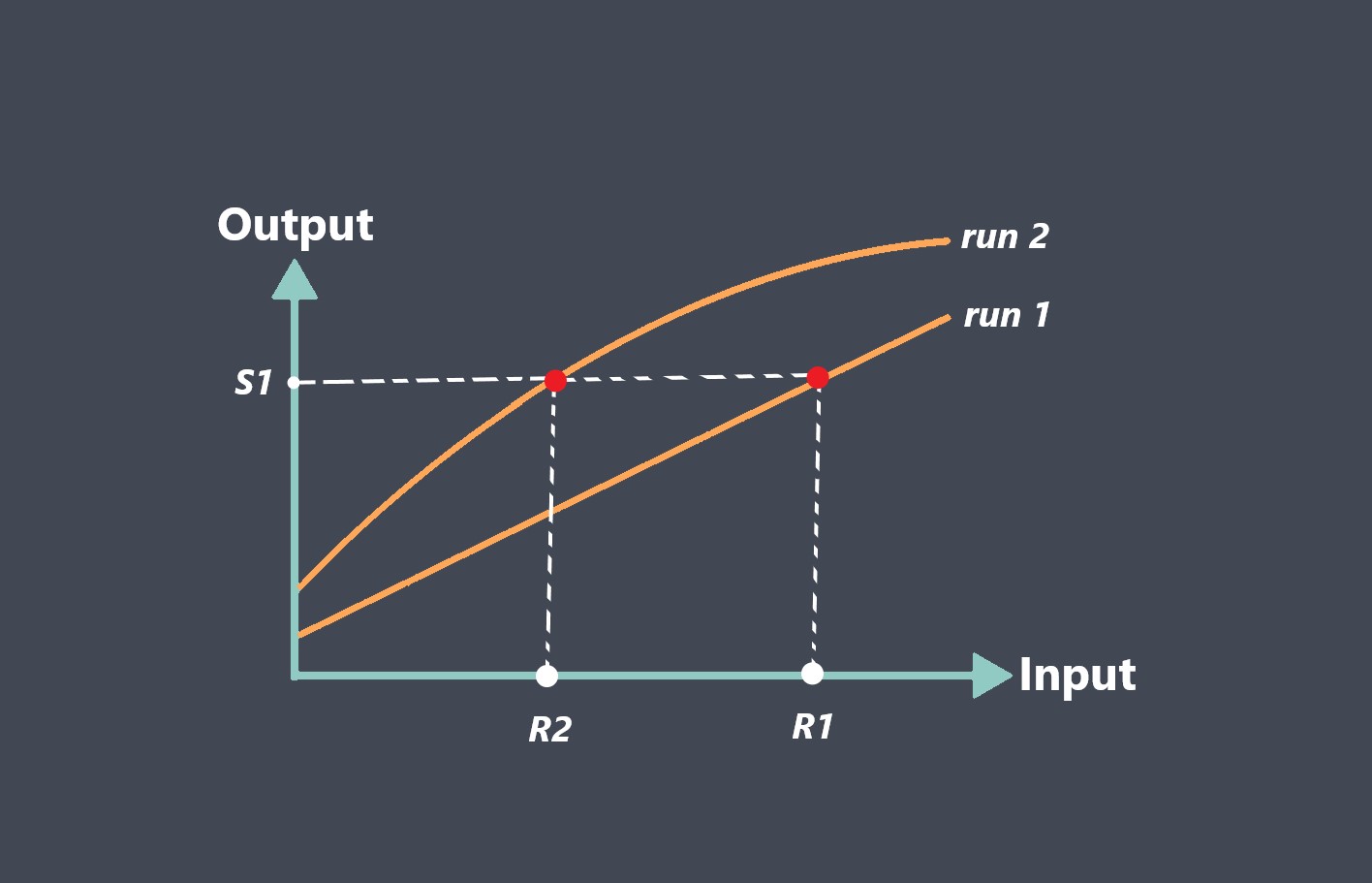

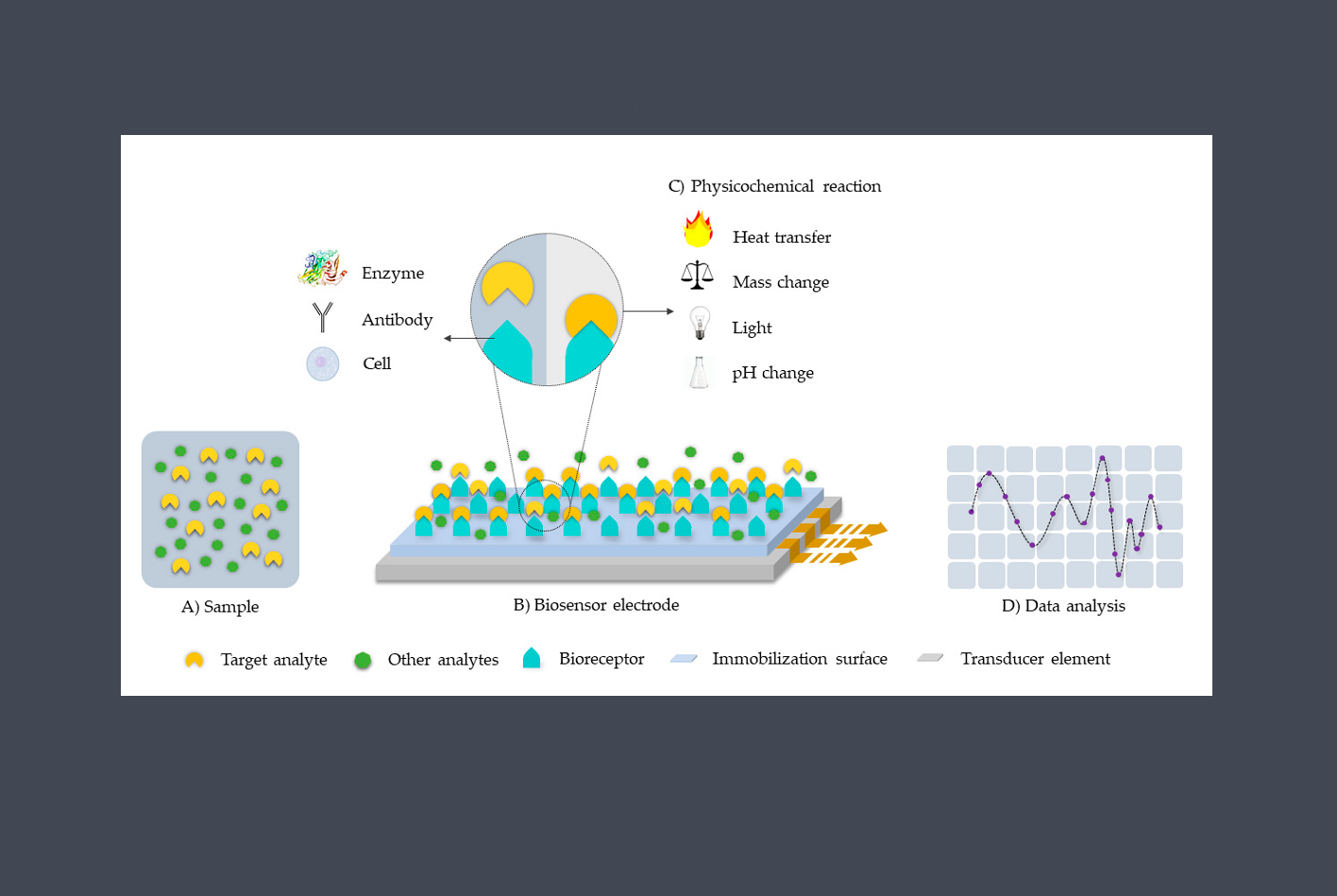

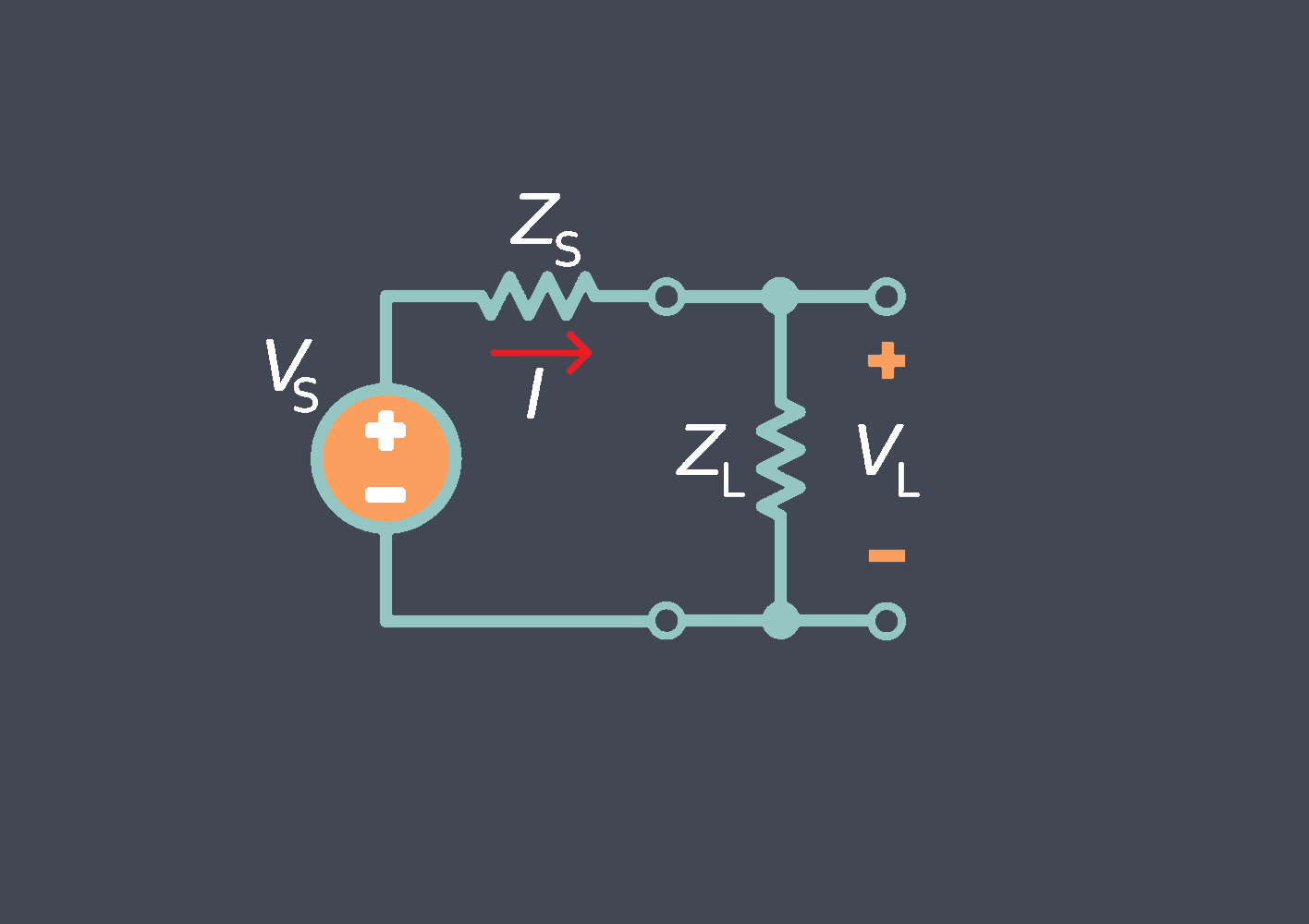

Different pressure sensors have different pressure ranges and sensitivities, making it crucial to choose a sensor suitable for the specific pressure conditions of the application. Operating a pressure sensor beyond its specified range can result in inaccurate measurements, sensor damage, or even failure.

High-pressure conditions can cause strain or deformation of the sensor’s diaphragm, affecting its mechanical properties and leading to measurement errors. Similarly, extremely low-pressure conditions can result in reduced sensitivity or inaccurate readings due to decreased signal strength.

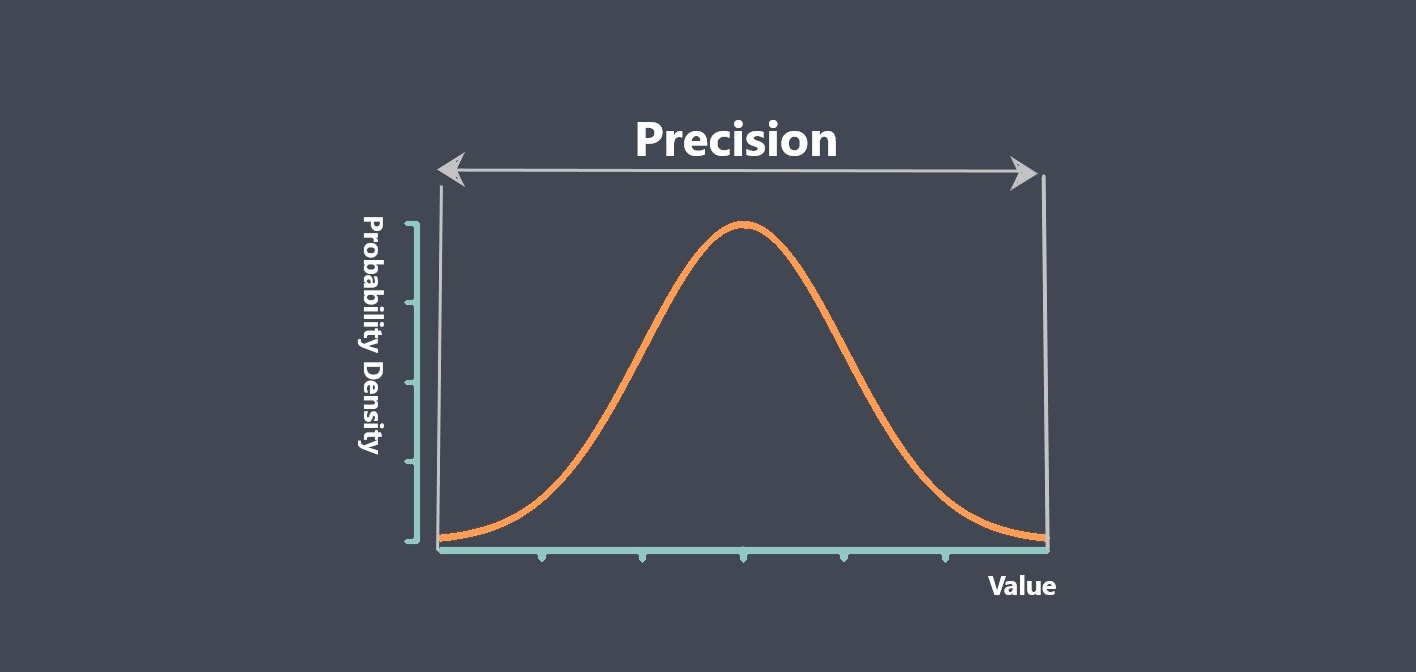

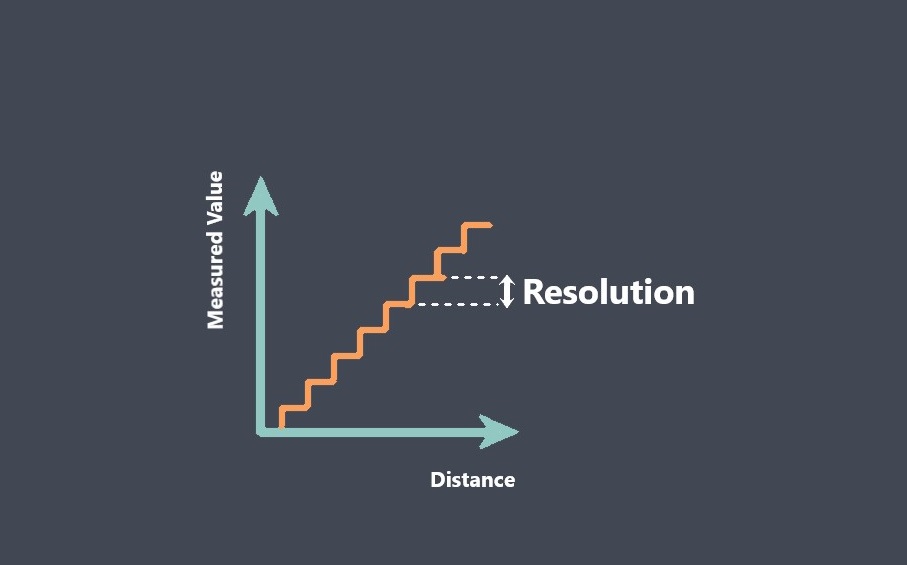

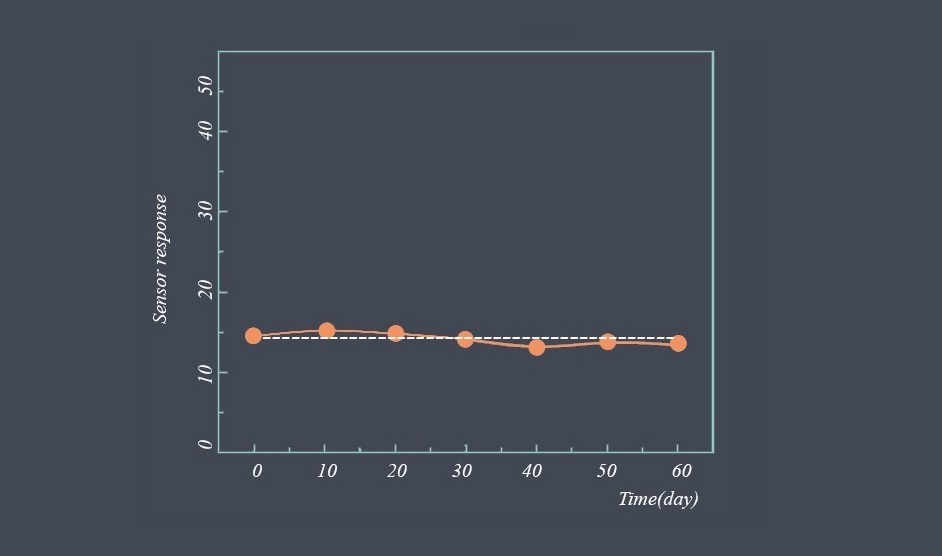

Understanding the pressure range of a sensor allows for proper selection and ensures accurate measurements in the target pressure range. It is important to consider factors such as the required measurement resolution, the anticipated pressure variations, and any potential transient or overpressure events that the sensor might encounter.

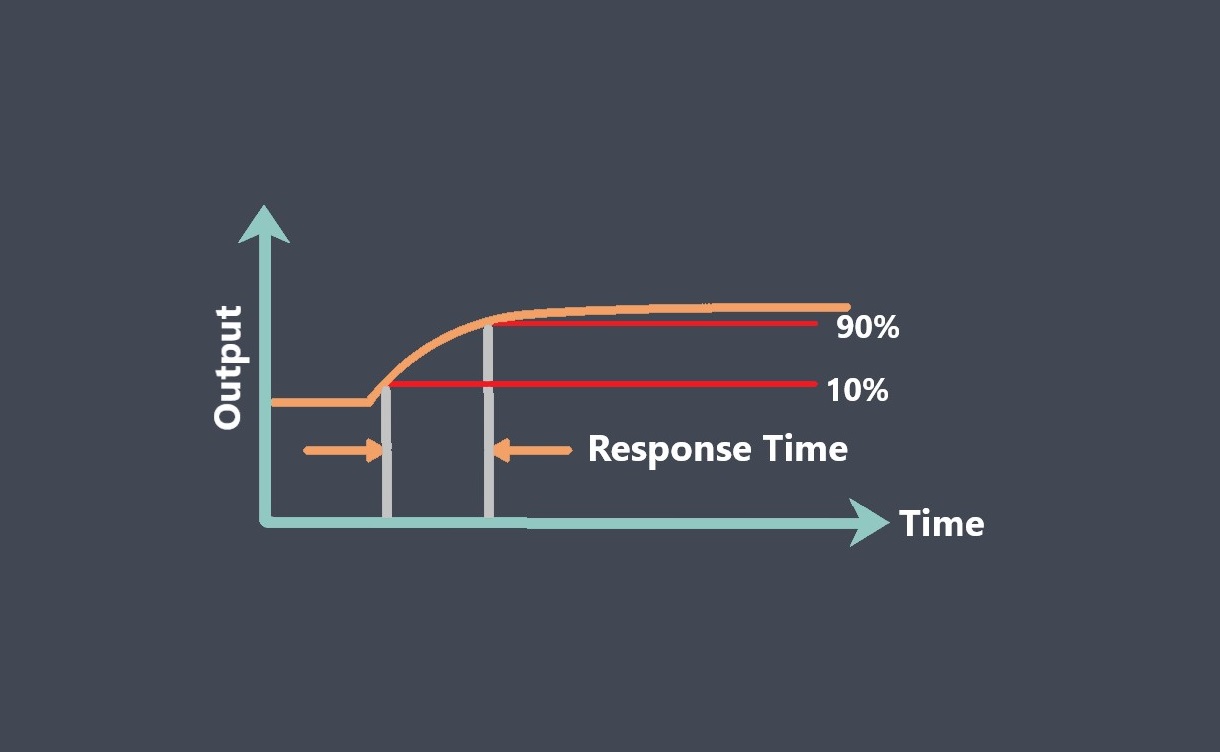

Some sensors may have a “fixed” pressure range, while others may have a “configurable” range that can be set by the user. It is important to select a sensor with a pressure range that is appropriate for the application, taking into account the expected pressure range, accuracy requirements, and other factors such as temperature range, response time, and environmental conditions.

By selecting a sensor with an appropriate pressure range and understanding its limitations, users can obtain reliable and accurate pressure measurements in their specific application, contributing to optimal system performance and operation.