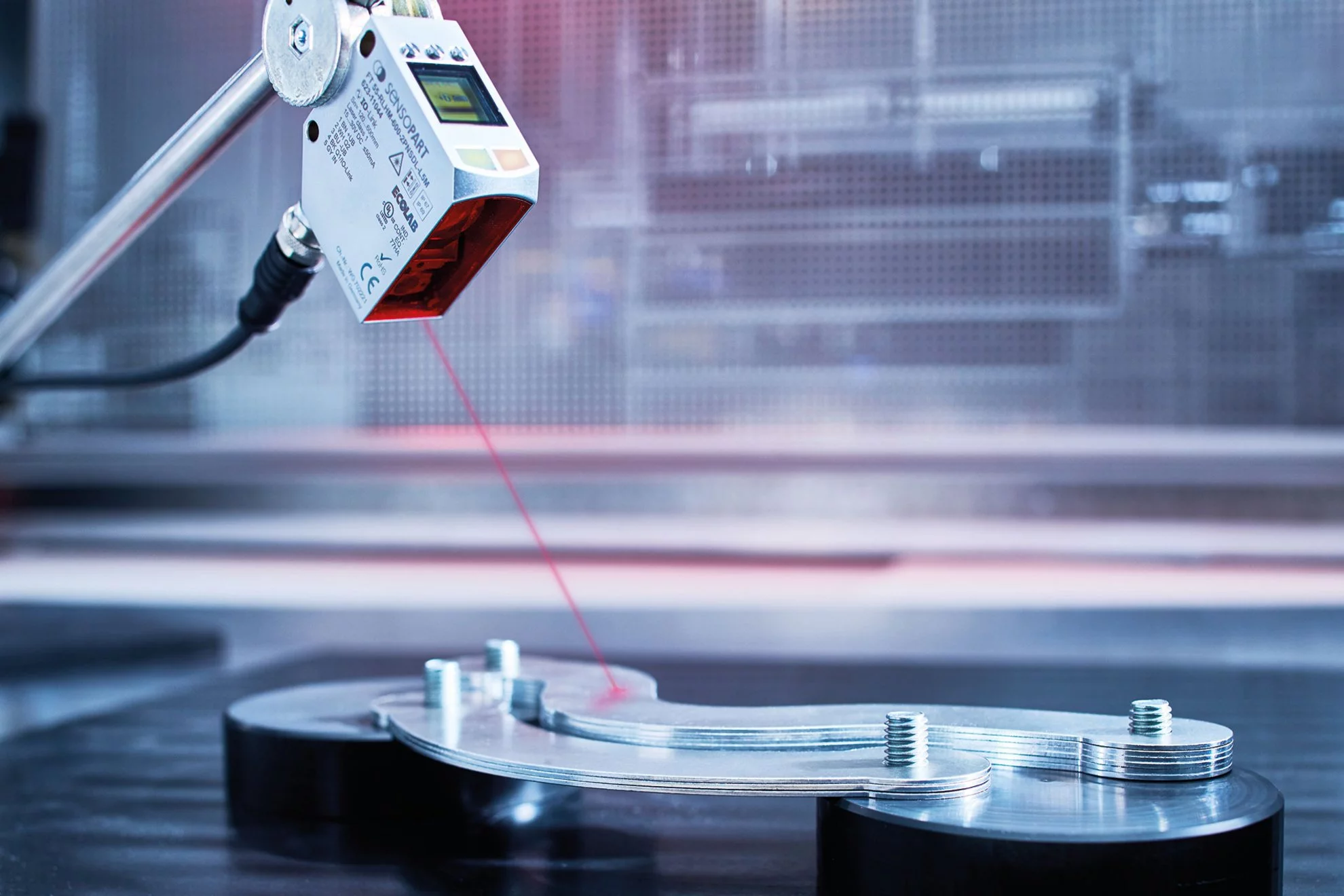

A proximity sensor detects the presence or absence of an object within a certain range without physical contact. Types include inductive, capacitive, and ultrasonic proximity sensors. Inductive sensors detect metal objects, capacitive sensors detect changes in capacitance, and ultrasonic sensors use sound waves to detect objects. Applications include object detection, automation systems, security systems, and touchless interfaces.

Proximity sensors are electronic devices that can detect the presence or absence of an object within a certain range without making physical contact. They work by emitting an electromagnetic field (such as infrared, magnetic, or capacitive) and measuring changes in that field caused by the presence of an object. Once these changes are detected, the sensor sends a signal to a controller or other devices to initiate a specified action, such as turning on a light, activating a door opener, or notifying a system of an object’s presence.

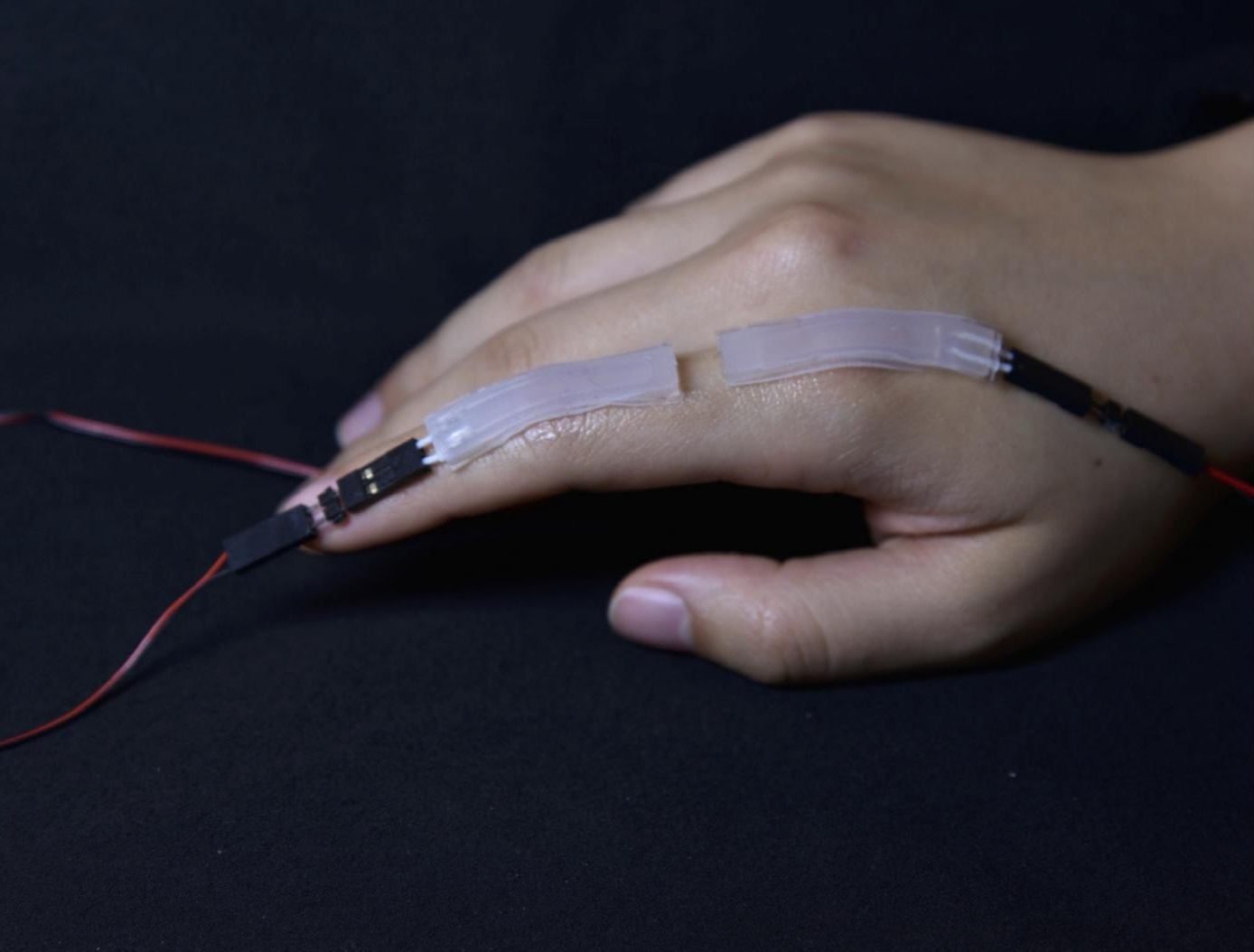

These sensors have many advantages over contact sensors because of their non-contact sensing ability. They are reliable, durable and require low maintenance and also they do not have any affect on the target object (such as physical movement or heat transfer to the object) and can be used in harsh environments.

Proximity sensors are widely used in various industries, such as manufacturing, automotive, robotics, and consumer electronics. They provide valuable data for automation, object detection, and safety applications.

Proximity sensors types and their working principle

Proximity sensors work by using various technologies to detect the presence or absence of an object within a certain range without making physical contact. There are many types of proximity sensors, and they each sense targets in distinct ways. Here is a general overview of how different types of proximity sensors work:

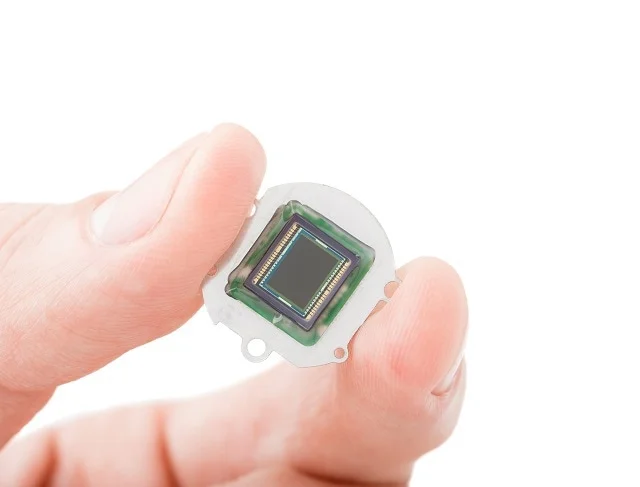

Infrared (IR) Proximity Sensors

Infrared (IR) proximity sensors are commonly used in various applications to detect the presence of objects within a certain range. These sensors emit infrared light and have a receiver that detects the reflection or intensity of the light. When an object comes within the sensor’s range, it reflects the emitted light back to the receiver, triggering a response.

Here’s a brief explanation of how IR proximity sensors work:

Emitting Infrared Light: The IR proximity sensor consists of an infrared light-emitting diode (LED) that emits infrared light in the form of invisible light waves.

Reflection Detection: The sensor also includes a receiver, which can be a photodiode or phototransistor. This receiver is positioned in such a way that it can detect the infrared light emitted by the LED.

Object Detection: When no object is present within the sensor’s range, the emitted infrared light propagates without any interruption and does not reach the receiver. In this case, the receiver does not receive any reflected infrared light. However, when an object enters the sensor’s range, it reflects some of the emitted infrared light back towards the receiver. The receiver detects the presence of this reflected light.

Proximity Determination: The sensor measures the intensity of the received reflected light or compares it to the emitted light’s intensity. By analyzing this information, the sensor determines the proximity of the object.

Triggering a Response: Based on the detected proximity, the sensor sends a signal to a controller or other devices to initiate a specific action, such as activating a switch, triggering an alarm, or adjusting an electronic display.

It’s important to note that different types of IR proximity sensors may use variations of this basic operating principle. For example, some sensors may modulate the emitted IR light and use demodulation techniques to improve accuracy and reliability. Nonetheless, the fundamental concept remains the same: detecting the presence of an object by analyzing the reflection or intensity of emitted infrared light.

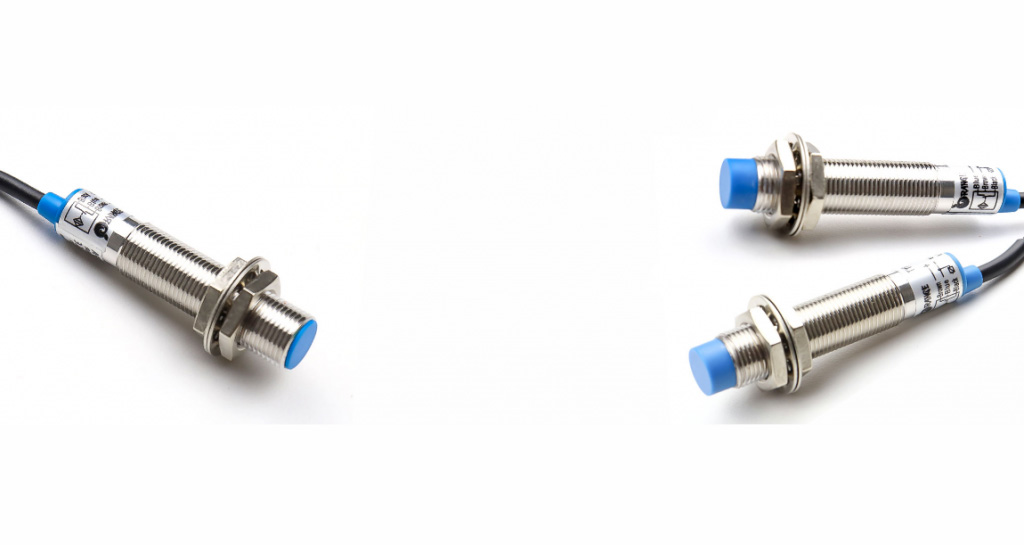

Magnetic Proximity Sensors

Magnetic proximity sensors are devices that use magnetic fields to detect the presence or absence of objects within a certain range. These sensors are commonly used in industrial and automation applications, as well as security systems. They work based on the principles of magnetism and the detection of changes in magnetic fields.

Here is a brief explanation of how magnetic proximity sensors operate:

Magnetic Field Generation: The sensor consists of a permanent magnet or an electromagnetic coil that generates a magnetic field around it.

Object Detection: When there is no object present within the sensor’s range, the magnetic field remains undisturbed. When an object enters the sensor’s range, it can either attract or repel the magnetic field generated by the sensor, depending on the properties of the object and the sensor.

Sensor Response: The proximity sensor detects the disturbance in the magnetic field caused by the presence of the object. This change in the magnetic field triggers a response in the sensor.

Output Signal: The sensor then sends an electrical signal or switches its output state to indicate the presence or absence of the object. This signal can be digital or analog, depending on the type of sensor.

Triggering a Response: Based on the sensor’s output signal, further actions can be triggered, such as activating a relay, sending a signal to a controller, or initiating an alarm.

There are different types of magnetic proximity sensors available, including reed switches, Hall effect sensors, and magnetoresistive sensors. Each type has its own specific characteristics and applications.

Magnetic proximity sensors offer advantages such as non-contact detection, long service life, resistance to dust and dirt, and ability to operate in harsh environments. However, they have limitations, including sensitivity to strong external magnetic fields and limited sensing range, which varies depending on the strength of the sensor’s magnetic field.

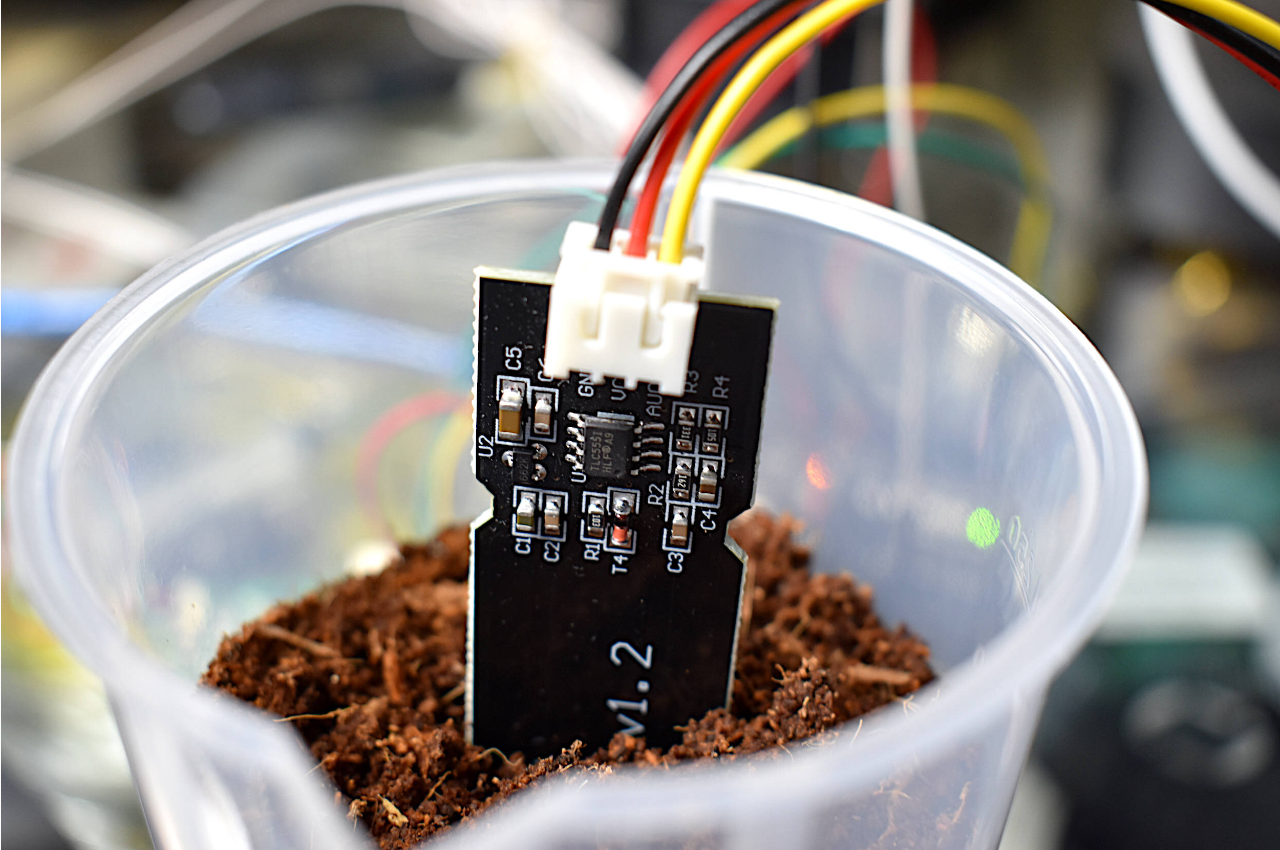

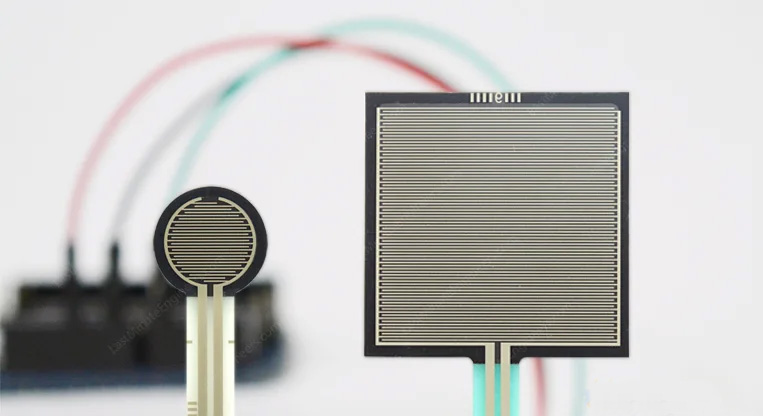

Capacitive Proximity Sensors

Capacitive proximity sensors are devices used to detect the presence or absence of objects based on changes in capacitance. These sensors utilize the principle of capacitive coupling to detect the proximity of an object without physical contact. They are commonly used in various industries, such as manufacturing, automotive, and consumer electronics.

Here is a brief explanation of how capacitive proximity sensors work:

Capacitive Coupling: The sensor contains two conductive plates, typically made of metal, which form a capacitor. One plate is formed by the sensor itself, while the other plate can be the target object or a separate electrode.

Electromagnetic Field: An AC voltage is applied to one of the plates (the sensor or the separate electrode), creating an electromagnetic field around it. This field extends into the surrounding area.

Object Detection: When an object enters the sensor’s range, it influences the electromagnetic field. The presence of the object alters the capacitance of the sensor’s plates.

Sensor Response: As the capacitance changes, the sensor detects this variation and responds to it.

Output Signal: The sensor generates an electrical signal based on the detected capacitance change. This signal can be either digital or analog, depending on the type of sensor.

Triggering a Response: The output signal from the sensor can be used to activate a relay, control a circuit, or provide input to a controller or microcontroller, triggering further actions.

Capacitive proximity sensors are sensitive to the dielectric properties of the objects being detected. Conductive and non-conductive materials will have different effects on the capacitance, allowing for discrimination between different types of objects.

Capacitive proximity sensors offer several benefits, including non-contact detection, high accuracy, immunity to dust and dirt, and the ability to work in harsh environments. However, they also have limitations, such as sensitivity to moisture and limited sensing range, which is influenced by the size and dielectric constant of the object being detected.

Overall, capacitive proximity sensors are versatile devices widely used for object detection and presence sensing in various applications.

Ultrasonic Proximity Sensors

Ultrasonic proximity sensors, also known as ultrasonic distance sensors or ultrasonic range finders, are devices used to detect the presence, distance, or movement of objects using ultrasonic waves. These sensors emit high-frequency sound waves and measure the time it takes for the waves to bounce back after hitting an object. Ultrasonic proximity sensors are commonly used in industries such as robotics, automation, parking systems, and security applications.

Here is a brief explanation of how ultrasonic proximity sensors work:

Sound Wave Emission: The sensor emits a burst of ultrasonic sound waves, typically in the frequency range of 20 kHz to 200 kHz. These sound waves are inaudible to humans.

Wave Propagation: The emitted sound waves travel through the air as a pressure wave, similar to how ripples form when a stone is thrown into water.

Object Detection: When the sound waves encounter an object in their path, they get reflected back towards the sensor.

Time Measurement: The sensor measures the time it takes for the reflected sound waves to return to the sensor. This is known as the “time of flight.”

Distance Calculation: Using the speed of sound in the medium (usually air), the sensor calculates the distance between itself and the object based on the time of flight.

Output Signal: The sensor provides an output signal that indicates the presence, distance, or movement of objects. This signal can be in the form of a digital signal, analog voltage, or current that can be utilized by controllers or other devices.

Ultrasonic proximity sensors have several advantages, including non-contact detection, wide detection range, immunity to colors or surface properties of objects, and high accuracy. They can detect both solid objects and liquid surfaces, making them suitable for various applications.

However, there are a few limitations to consider. The accuracy of ultrasonic sensors can be affected by environmental conditions, such as temperature, humidity, and air composition. Additionally, certain materials with soft or absorbent surfaces may absorb or scatter sound waves, affecting the sensor’s performance.

In summary, ultrasonic proximity sensors are commonly used devices that use the principles of sound wave reflection to detect the presence and measure the distance of objects. They offer reliable and versatile sensing capabilities in various industrial and consumer applications.