A gas sensor detects and measures the concentration of specific gases in the air. It is used for gas leak detection, air quality monitoring, and safety applications.

A gas sensor is a device used to detect and measure the presence or concentration of various gases in the surrounding environment. These sensors are designed to detect specific gases or a range of gases, depending on their intended application.

They are commonly used to detect toxic or explosive gasses and measure gas concentration. Gas sensors are usually used in factories and manufacturing facilities to identify gas leaks, and to detect smoke and carbon monoxide in homes. Gas sensors have so many different types which vary widely in size (portable and fixed), range, and sensing ability. Depending on their intended environments and functions, the physical makeup and sensing process can vary notably between sensors. They are often part of a larger embedded system, such as security systems, and are usually connected to an audible alarm or interface. Due to the constant interaction of gas sensors with air and various gases, they need calibration more than many other types of sensors.

Gas sensors classification

Gas sensors work on the principle of transforming the gas adsorption effects on the surface of the active material into a detectable signal in terms of its changed electrical, optical, thermal, mechanical, magnetic (magnetization and spin), and piezoelectric properties.

Gas sensors are typically classified into various types based on their target gas, different usage methods, sampling methods, different functions, and their detection principles, etc…

Here are some examples of different types of gas sensors classifications:

Based on different gas types

it can be divided into combustible gas sensors (often using catalytic combustion, infrared, thermal conductivity, semiconductor type), toxic gas sensors (generally using electrochemical, metal-semiconductor, photoionization, flame ionization), Harmful gas sensors (often infrared, ultraviolet, etc.), oxygen (often paramagnetic, zirconia) and other types.

Based on their usage methods

Gas sensors can be divided into portable gas detectors and fixed gas detectors.

Based on their functions

These sensors are available in two single gas sensor and composite gas sensor. single gas sensors can detect just one gas while composite gas sensors can detect multiple gases at the same time

Gas sensors types based on their working principle

The most commonly used gas sensor classification is classification based on their working principles. In the following we gonna talk about different types of gas sensor and their working principles:

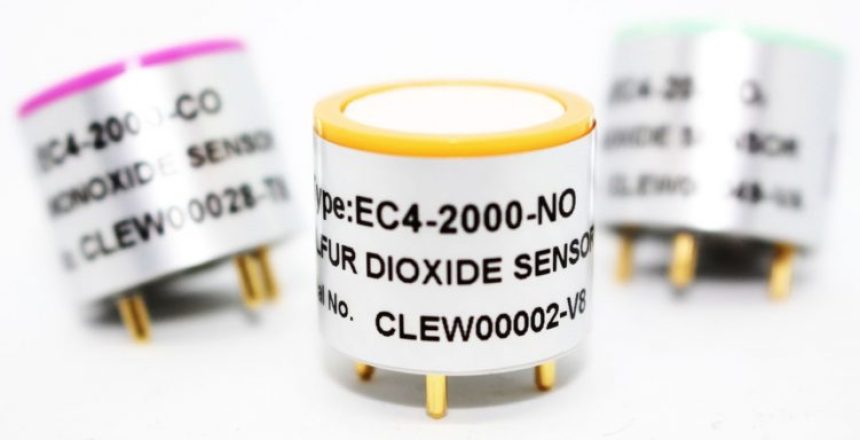

Electrochemical gas sensors

Electrochemical gas sensors are a type of gas sensor that operates based on electrochemical principles. They are commonly used to detect and measure the concentration of various gases in different environments. The main components of this sensor include: a sensing electrode, a reference electrode, and an electrolyte.

When the target gas comes into contact with the sensing electrode, it undergoes a series of chemical reactions, which result in the production or consumption of electrons. This electron flow generates a small electrical current that can be measured.

The magnitude of the current is directly proportional to the concentration of the gas being detected. By calibrating the sensor with known gas concentrations, it is possible to determine the gas concentration based on the measured current.

Electrochemical gas sensors advantages and disadvantages:

Electrochemical gas sensors offer several advantages such as high sensitivity, accuracy, and selectivity to specific gases. They can detect a wide range of gases, including toxic gases like carbon monoxide (CO), hydrogen sulfide (H2S), and chlorine (Cl2), as well as flammable gases like methane (CH4) and propane (C3H8).

However, there are some limitations to consider when using electrochemical gas sensors. They may have a limited lifespan due to the gradual depletion of the sensor’s active components. Additionally, cross-sensitivity to other gases or environmental factors can affect the accuracy of the measurements. Regular calibration and maintenance are necessary to ensure optimal performance.

Electrochemical gas sensors applications:

Electrochemical gas sensors find applications in various fields, such as industrial safety, indoor air quality monitoring, personal safety devices, and environmental monitoring. They are widely used in industries like manufacturing, mining, oil and gas, and firefighting to detect and monitor hazardous gases and ensure the safety of workers and the environment.

Photoionization detectors (PID)

Photoionization detectors (PIDs) are gas detection devices that use ultraviolet (UV) light to ionize molecules and measure gas concentrations in the air. They are commonly used for monitoring volatile organic compounds (VOCs) and hazardous gases in industrial environments, as well as in environmental and indoor air quality assessments.

The Photoionization detectors consist of an ionization chamber for letting in the target gas, an ultraviolet lamp for applying light, and positive and negative electrodes for detecting ion currents.

When the gas enters the ionization chamber and is exposed to ultraviolet light from the light source (ultraviolet lamp), the gas releases electrons and generates cations.

The generated cations and electrons are drawn by the positive and negative electrodes, so a current will be generated. This current is proportional to the gas concentration, so by measuring the current value, the concentration of the target gas will be determined.

To ionize a gas, the photon energy should be larger than the ionization energy specific to that gas. Photon energy is expressed in the unit electron volt (eV). Usually a high-energy UV lamp (typically with a wavelength of 10.6 eV) will be used in this type of sensors. The larger the photon energy is, the larger the amount of detectable gas the sensor can ionize.

PIDs are highly sensitive and can detect a wide range of VOCs and gases, including benzene, toluene, xylene, formaldehyde, ethylene oxide, and many others.

Photoionization detectors (PIDs) advantages and disadvantages:

One of the advantages of PIDs is their real-time response, providing immediate feedback on gas levels. They are also portable, lightweight, and easy to use, making them suitable for field applications. PIDs often have a wide detection range, allowing for measurements from parts per billion (ppb) to thousands of parts per million (ppm).

However, They also have some limitations. They are specific to the types of gases they are designed to detect and may not be suitable for other gases. The response of PIDs can also be affected by factors such as humidity, temperature, and interferences from other substances. Regular calibration and maintenance are necessary to ensure accurate and reliable measurements.

Photoionization detectors (PIDs) applications:

PIDs are valuable tools for quickly identifying and quantifying airborne volatile compounds and hazardous gases. They find applications in various industries, including chemical manufacturing, oil and gas, environmental monitoring, and occupational safety, helping to protect workers and ensure the safety of the surrounding environment.

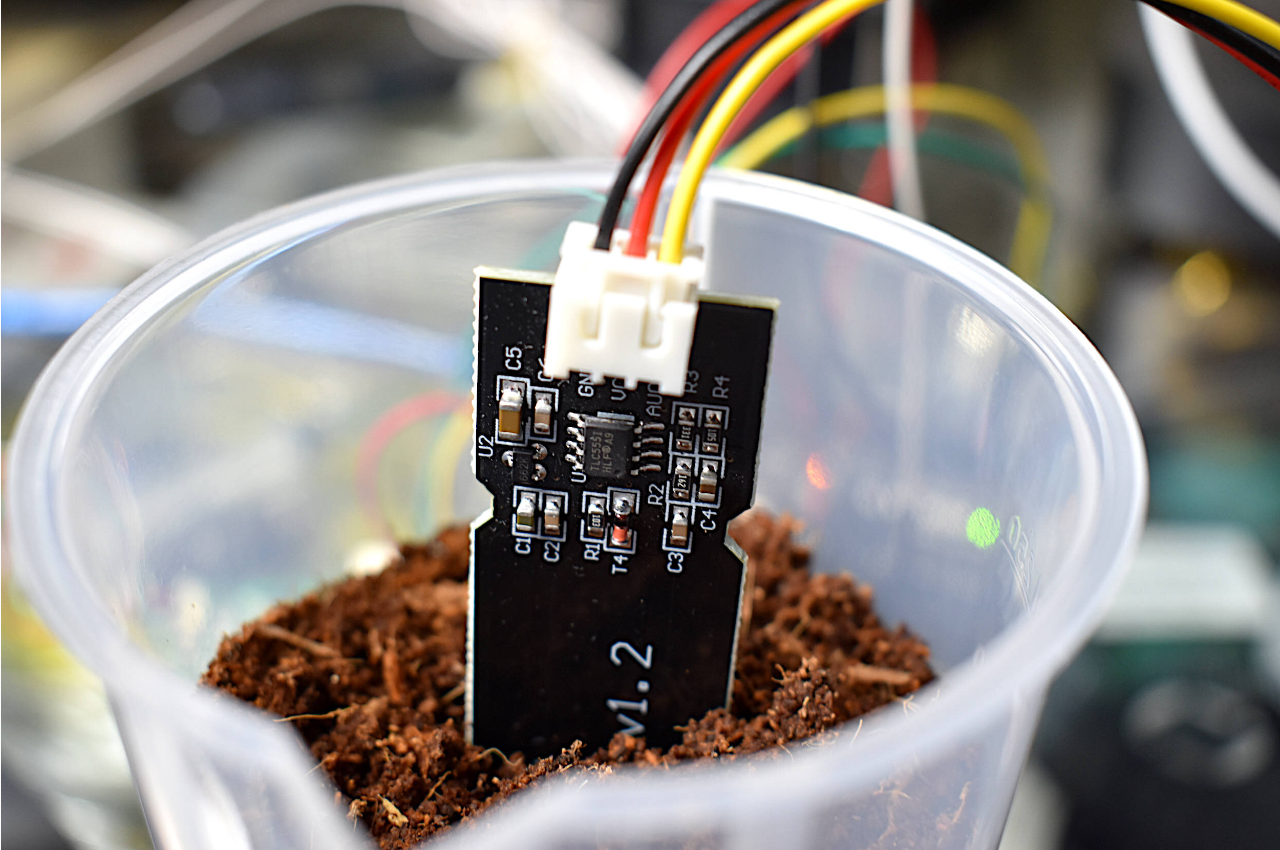

Semiconductor gas sensors

Semiconductor gas sensors are devices that utilize semiconductor materials to detect and measure the presence of specific gases in the air. They are commonly used for monitoring toxic gases, such as carbon monoxide (CO), nitrogen dioxide (NO2), hydrogen sulfide (H2S), and volatile organic compounds (VOCs), in various applications, including industrial safety, environmental monitoring, and indoor air quality assessments.

The working principle of semiconductor gas sensors involves the interaction between the target gas molecules and the semiconductor material. When the gas molecules come into contact with the sensor’s surface, they undergo chemical reactions that cause changes in the electrical properties of the semiconductor material.

Typically, the semiconductor material is a metal oxide such as tin dioxide (SnO2). In the absence of the target gas, the surface of the sensor is typically in an oxidized state, and electrical resistance is high. However, when the target gas is present, it reacts with the surface of the sensor, leading to a reduction in the surface oxidation and a decrease in electrical resistance.

By measuring the change in electrical resistance, semiconductor gas sensors can determine the concentration of the target gas.

Semiconductor gas sensors advantages and disadvantages:

The response time of these sensors is generally rapid, allowing for real-time monitoring of gas levels. They are also relatively cost-effective, compact, and have low power requirements, making them suitable for a wide range of applications but they may have limitations. They are selective to specific gases and may not be responsive to other gases or volatile compounds. Interferences from humidity, temperature variations, and other gases can affect their accuracy. Regular calibration and maintenance are necessary to ensure reliable and accurate measurements.

Semiconductor gas sensors applications:

semiconductor gas sensors provide a convenient and effective means of detecting and monitoring various gases in different environments. Their widespread use in industries and applications highlights their importance in ensuring safety, controlling pollution, and maintaining good air quality.

Catalytic bead sensors

Catalytic bead sensors are gas detection devices that use a catalytic reaction to detect and measure the presence of flammable gases in the air. They are commonly utilized for monitoring gases such as methane (CH4), propane (C3H8), hydrogen (H2), and others in various applications, including industrial safety, leak detection, and combustion control.

Catalytic bead sensors are based on the principle of combustion. They consist of two small platinum-coated beads, often made of alumina or silica. One bead is coated with a catalyst (usually platinum or palladium) that promotes the oxidation of the target gas, while the other bead acts as a reference. When the target gas comes into contact with the catalytic bead, it undergoes an exothermic combustion reaction, producing heat. The catalyst helps lower the activation energy required for the gas to react. This combustion reaction leads to an increase in temperature of the catalytic bead.

A built-in resistor measures the change in temperature of the catalytic bead caused by the combustion reaction. As the temperature rises, the electrical resistance of the bead increases proportionally. By monitoring the change in resistance of the catalytic bead, the sensor can determine the concentration of the target gas. The resistance is measured using a Wheatstone bridge circuit or another suitable measurement technique.

Catalytic bead sensors advantages and disadvantages:

Catalytic bead sensors offer several advantages, including fast response times, high sensitivity, and wide detection ranges. They are suitable for detecting a variety of flammable gases, and their response is not affected by changes in humidity or oxygen levels. Additionally, they are relatively inexpensive, durable, and require minimal maintenance.

However, catalytic bead sensors do have limitations. They are specific to flammable gases and may not be suitable for detecting non-flammable or toxic gases. They are also prone to false alarms from certain substances, such as silicone vapors and some solvents. Furthermore, their catalytic surfaces can be poisoned or deactivated by certain compounds, requiring regular calibration and maintenance to ensure accuracy.

Catalytic bead sensors applications:

catalytic bead sensors are widely used for flammable gas detection due to their reliability, affordability, and effectiveness. They play a crucial role in ensuring the safety and protection of personnel and facilities in various industries.

Infrared gas sensors

Infrared gas sensors are devices that use infrared radiation to detect and measure the presence of gases in the air. They are commonly used for monitoring flammable gases, such as methane (CH4), propane (C3H8), and butane (C4H10), as well as carbon dioxide (CO2) and other gases in various applications, including industrial safety, leak detection, and environmental monitoring.

The working principle of infrared gas sensors is based on the absorption of infrared radiation by gases. Each gas has a unique absorption spectrum in the infrared region, meaning it absorbs infrared radiation at specific wavelengths. The sensor contains an infrared source that emits radiation at various wavelengths, and a detector that measures the amount of radiation transmitted through or absorbed by the gas sample.

Infrared gas sensors may use different types of infrared radiation sources, such as incandescent lamps or light-emitting diodes (LEDs), depending on the desired wavelength range and sensitivity. They also utilize different detection techniques, including non-dispersive infrared (NDIR) and tunable diode laser absorption spectroscopy (TDLAS).

- NDIR sensors

In NDIR sensors, the emitted infrared radiation passes through the gas sample, and the detector measures the amount of radiation that reaches it. The presence of the target gas causes absorption of specific wavelengths, resulting in a decrease in the detected radiation intensity. The amount of absorbed radiation is proportional to the gas concentration, allowing for accurate measurement.

- TDLAS sensors

TDLAS (Tunable Diode Laser Absorption Spectroscopy) sensors utilize the principle of absorption spectroscopy, specifically employing a tunable diode laser as the light source. They analyze the characteristic absorption lines of the target gas to determine its concentration.

The sensor employs a tunable diode laser that emits infrared light at a specific wavelength corresponding to the absorption line of the target gas. The laser’s wavelength can be precisely adjusted over a range to match the desired absorption line.

The emitted laser beam passes through the gas sample containing the target gas. If the target gas is present, it will absorb some of the infrared light at the specific wavelength defined by its absorption line.

The sensor measures the intensity of the laser light before and after it passes through the gas sample. By comparing the two intensities, it quantifies the amount of light absorbed by the target gas.

Infrared gas sensors advantages and disadvantages:

Infrared gas sensors offer several advantages, including high sensitivity, selectivity, and stability. They can detect gases over a wide concentration range and operate in various environmental conditions. But, they may require periodic calibration to maintain accuracy and compensate for any aging effects.

Infrared gas sensors applications:

infrared gas sensors are valuable tools for gas detection and safety applications, ensuring the early detection and prevention of hazardous situations.