Sensors

GebraBit

Sensors

A sensor is a device that detects and responds to a physical stimulus, such as light, heat, pressure, or motion, and converts it into an electrical or digital signal that can be processed by a control system. Sensors are used in a wide range of applications, including manufacturing, automation, robotics, automotive, aerospace, medical, and consumer electronics.

The basic function of a sensor is to detect a physical quantity or parameter and convert it into an electrical or digital signal that can be read and processed by a control system. There are many different types of sensors

We continue the innovation of our Sensors with our latest

Sensors

This sensors are ready to use as well as customize easily.

Medical

Motion Tracking

Enviromental

Frequently Asked Questions

40 important sensor parameters:

- Sensitivity: This refers to the change in output signal for a given change in input signal.

- Range: This is the minimum and maximum values that a sensor can measure.

- Accuracy: This refers to how close the sensor reading is to the true value.

- Resolution: This is the level of repeatability in the sensor’s measurements.

- Resolution: This refers to the smallest change in input signal that the sensor can detect.

- Drift: This refers to the gradual change in sensor output over time.

- Hysteresis: This is the difference in sensor output for the same input signal, depending on whether the input signal is increasing or decreasing.

- Response time: This is the amount of time it takes for the sensor to respond to a change in input signal.

- Noise: This is the random variation in the sensor output signal that is not related to the input signal.

- Offset: This is the degree to which the sensor output changes in proportion to the input signal.

- Operating temperature range: This refers to the range of temperatures within which the sensor can operate correctly.

- Humidity range: This is the range of humidity levels within which the sensor can operate correctly.

- Pressure range: This is the range of pressures that the sensor can measure accurately.

- Power consumption: This is the amount of power that the sensor requires to operate.

- Physical size: This refers to the size of the sensor itself.

- Weight: This refers to the weight of the sensor.

- Calibration: This refers to the process of adjusting the sensor to ensure its accuracy.

- Environmental protection: This refers to the level of protection that the sensor has against dust, water, and other environmental factors.

- Interference: This refers to the degree to which the sensor is affected by other sources of electromagnetic or radio frequency interference.

- Output signal: This refers to the type of signal that the sensor outputs, such as analog or digital.

- Transfer function: This is the mathematical relationship between the input signal and the output signal of the sensor, typically expressed as an equation.

- Full-scale input and output: This refers to the maximum input and output values of the sensor. It is important to know these values in order to properly calibrate and interpret the sensor’s readings.

- Saturation: This refers to the point at which the sensor can no longer accurately measure the input signal, often resulting in a maximum or minimum output signal. It is important to understand the saturation limits of the sensor to avoid errors and ensure accuracy in measurements.

- Repeatability: This is the ability of the sensor to provide the same output signal for the same input signal over multiple measurements.

- Stability: This refers to the ability of the sensor to maintain its performance over time.

- Cross-sensitivity: This is the degree to which the sensor output is affected by other environmental factors, such as temperature or humidity.

- Offset: This is the difference between the actual output signal and the expected output signal at zero input.

- Signal-to-Noise Ratio (SNR): This is the ratio of the desired signal to the noise in the output signal.

- Sensing element: This refers to the physical component of the sensor that is responsible for converting the input signal into an output signal.

- Response curve: This is the graph that shows the relationship between the input signal and the output signal of the sensor. It can be used to determine the sensitivity, linearity, and saturation limits of the sensor.

- Selectivity: This refers to the ability of the sensor to distinguish between the target substance and other substances that may be present in the environment.

- Sensing range: This is the range of values over which the sensor can accurately measure the input signal.

- Input impedance: This is the resistance of the sensor to the flow of current from the input signal.

- Output impedance: This is the resistance of the sensor to the flow of current to the output signal.

- Bandwidth: This refers to the range of frequencies over which the sensor can accurately detect the input signal.

- Stability under varying conditions: This refers to the ability of the sensor to maintain its performance under changing environmental conditions.

- Cross-talk: This is the degree to which the sensor output is affected by signals from other sensors or sources.

- Operating lifetime: This is the expected lifetime of the sensor under normal operating conditions.

- Cost: This refers to the cost of the sensor, which can be an important factor in selecting a sensor for a given application.

- Availability: This refers to the availability of the sensor, including lead time, supply chain issues, and the ability to obtain replacements or spare parts.

2 important performance characteristics of a sensor

Accuracy: This refers to how closely the sensor’s output corresponds to the true or expected value of the parameter being measured. An accurate sensor will provide measurements that are very close to the true value of the parameter. The accuracy of a sensor is usually expressed as a percentage of the full-scale reading or as an absolute value.

Correctness: This refers to whether the sensor’s output is correct for the application. Correctness takes into account other factors such as the range, resolution, and stability of the sensor, as well as environmental factors such as temperature and humidity. A correct sensor will provide measurements that are appropriate for the application and meet the required specifications.

It’s important to note that accuracy and correctness are not the same thing. A sensor can be accurate but incorrect for the application if its range, resolution, or stability is not appropriate for the application. Similarly, a sensor can be correct for the application but not accurate if its measurements are consistently offset from the true value.

To ensure that a sensor is both accurate and correct for a particular application, it’s important to carefully consider the sensor’s specifications and characteristics, as well as the requirements and environmental conditions of the application. It’s also important to periodically calibrate the sensor to ensure that it continues to provide accurate and correct measurements over time.

Sensors based on their detection parameters

Sensors can be classified based on the detection parameters they measure. Some examples of sensor types based on detection parameters are:

Physical sensors: These sensors measure physical parameters such as temperature, pressure, light, motion, and vibration.

Chemical sensors: These sensors measure chemical parameters such as pH, gas concentration, and specific chemical substances.

Electrical sensors: These sensors measure electrical parameters such as voltage, current, and resistance.

Magnetic sensors: These sensors measure magnetic parameters such as magnetic field strength.

Acoustic sensors: These sensors measure sound parameters such as sound intensity and frequency.

Optical sensors: These sensors measure light parameters such as wavelength and intensity.

Biological sensors: These sensors measure biological parameters such as pulse, blood pressure, and blood glucose level.

Some sensors may be able to detect a combination of these parameters. For example, a gas sensor may detect both the concentration of a specific gas and the temperature and humidity of the surrounding environment.

What are the main types of sensors?

- Temperature sensors: These sensors detect and measure the temperature of a physical environment, and are commonly used in HVAC systems, industrial processes, and medical devices.

- Pressure sensors: These sensors detect and measure the pressure of a fluid or gas, and are commonly used in automotive, aviation, and medical applications.

- Light sensors: These sensors detect and measure the amount of light in an environment, and are commonly used in photography, automotive, and environmental monitoring.

- Motion sensors: These sensors detect and measure motion or movement, and are commonly used in security systems, robotics, and gaming.

- Proximity sensors: These sensors detect the presence or absence of an object in close proximity, and are commonly used in automotive, robotics, and industrial automation.

- Humidity sensors: These sensors detect and measure the amount of moisture in the air or in a substance, and are commonly used in HVAC systems and food storage.

- Magnetic sensors: These sensors detect and measure magnetic fields, and are commonly used in navigation, robotics, and industrial automation.

- Gas sensors: These sensors detect and measure the presence of various gases, and are commonly used in air quality monitoring, automotive, and industrial safety.

- Accelerometers: These sensors measure acceleration or vibration, and are commonly used in automotive, aerospace, and industrial machinery.

- Gyroscopes: These sensors measure angular velocity or rotation, and are commonly used in navigation, robotics, and aerospace.

- Infrared sensors: These sensors detect and measure infrared radiation, and are commonly used in remote sensing, temperature measurement, and security systems.

- Ultrasonic sensors: These sensors use sound waves to detect and measure distance or motion, and are commonly used in automotive, robotics, and industrial automation.

- pH sensors: These sensors measure the acidity or alkalinity of a substance, and are commonly used in water quality monitoring and chemical analysis.

- Flow sensors: These sensors measure the flow rate of a fluid, and are commonly used in fuel consumption measurement and fluid control.

- Level sensors: These sensors measure the level of a liquid or solid in a container or vessel, and are commonly used in fuel tanks, water tanks, and silos.

- Force sensors: These sensors measure the force or pressure applied to an object, and are commonly used in robotics, industrial machinery, and medical devices.

- Sound sensors: These sensors detect and measure sound waves, and are commonly used in acoustic testing, noise monitoring, and speech recognition.

- Radiation sensors: These sensors detect and measure ionizing radiation, and are commonly used in nuclear power plants, medical imaging, and radiation therapy.

- Image sensors: These sensors convert optical images into electrical signals, and are commonly used in digital cameras, surveillance systems, and machine vision.

- Hall effect sensors: These sensors detect and measure magnetic fields, and are commonly used in automotive, robotics, and industrial automation.

- Electrochemical sensors: These sensors use chemical reactions to detect and measure the presence of various substances, and are commonly used in gas detection and environmental monitoring.

- Optical sensors: These sensors use light to detect and measure a physical parameter, such as the presence or absence of an object, the color or intensity of light, or the distance between objects. They are commonly used in optical encoders, barcode readers, and machine vision.

- Strain sensors: These sensors measure the amount of strain or deformation in an object, and are commonly used in structural monitoring, materials testing, and load cells.

- Tilt sensors: These sensors measure the angle of inclination or tilt of an object, and are commonly used in leveling systems, robotics, and aerospace.

- Touch sensors: These sensors detect and measure touch or pressure applied to a surface, and are commonly used in touch screens, keypads, and medical devices.

- Vibration sensors: These sensors measure the amplitude, frequency, or acceleration of vibrations, and are commonly used in structural monitoring, machinery diagnostics, and automotive testing.

- Moisture sensors: These sensors measure the moisture content of a substance, such as soil or wood, and are commonly used in agriculture, construction, and environmental monitoring.

- Weight sensors: These sensors measure the weight or mass of an object, and are commonly used in industrial scales, automotive testing, and medical devices.

- Color sensors: These sensors detect and measure color, and are commonly used in color detection, quality control, and machine vision.

- Proximity switches: These sensors detect the presence or absence of an object in close proximity, and are commonly used in industrial automation, robotics, and security systems.

These sensors are just a few examples of the many different types of sensors available. The selection of a sensor will depend on the specific requirements of the application, including the physical parameter to be measured, the range of measurement, the accuracy and precision required, and the environmental conditions of the application.

What is a Temperature sensor?

A temperature sensor is used to measure the temperature of an object or environment. It converts temperature into an electrical signal for interpretation. Types include thermocouples, RTDs, thermistors, and infrared temperature sensors. Thermocouples use voltage changes between two metals, RTDs rely on the resistance change of metals, thermistors use resistance changes in semiconductors, and infrared sensors detect thermal radiation. Applications include HVAC systems, industrial processes, medical devices, and weather monitoring.

Thermocouples: Commonly used in industrial applications and harsh environments.

RTDs: Suitable for precise temperature measurement in laboratories and industries.

Thermistors: Cost-effective and widely used in consumer electronics and temperature control systems.

Infrared Temperature Sensors: Non-contact measurement suitable for industrial processes, medical applications, and home automation.

Applications: Temperature monitoring in HVAC systems, temperature control in industrial processes, medical temperature measurement, weather monitoring systems.

What is a Pressure sensor?

A pressure sensor measures the pressure of a gas or liquid and converts it into an electrical signal. Types include piezoresistive, capacitive, and optical pressure sensors. Piezoresistive sensors utilize the change in resistance under pressure, capacitive sensors measure the change in capacitance, and optical sensors use the deflection of light to determine pressure. Applications include industrial automation, automotive systems, medical devices, and aerospace.

Piezoresistive Pressure Sensors: Commonly used in automotive applications and industrial processes.

Capacitive Pressure Sensors: Suitable for precise pressure measurements and low-pressure applications.

Optical Pressure Sensors: Used in high-pressure environments and critical applications.

Applications: Pressure monitoring in industrial automation, tire pressure measurement in automotive systems, blood pressure measurement in medical devices, aircraft cabin pressure control in aerospace.

What is a Humidity sensor?

A humidity sensor measures the moisture content or relative humidity of the surrounding environment. Types include capacitive, resistive, and thermal conductivity humidity sensors. Capacitive sensors measure changes in capacitance, resistive sensors use changes in resistance, and thermal conductivity sensors detect changes in thermal conductivity. Applications include HVAC systems, weather monitoring, food processing, and pharmaceutical storage.

Capacitive Humidity Sensors: Widely used due to their accuracy and stability.

Resistive Humidity Sensors: Suitable for cost-effective humidity measurements.

Thermal Conductivity Humidity Sensors: Ideal for high-temperature and high-humidity environments.

Applications: Humidity control in HVAC systems, weather forecasting and monitoring, food quality control in processing plants, humidity control in pharmaceutical storage.

What is a light sensor?

A light sensor detects and measures the intensity or presence of light. Types include photodiodes, phototransistors, and ambient light sensors. Photodiodes convert light into a current, phototransistors amplify the current, and ambient light sensors detect the overall light level. Applications include automatic lighting systems, display brightness control, proximity detection, and solar energy monitoring.

Photodiodes: Used for precise light intensity measurements and optical communications.

Phototransistors: Provide amplified output and are commonly used in light-dependent circuits.

Ambient Light Sensors: Adjust display brightness based on ambient light conditions.

Applications: Automatic lighting control in buildings, brightness adjustment in displays, proximity detection in touchless interfaces, monitoring solar panel performance.

What is a proximity sensor?

A proximity sensor detects the presence or absence of an object within a certain range without physical contact. Types include inductive, capacitive, and ultrasonic proximity sensors. Inductive sensors detect metal objects, capacitive sensors detect changes in capacitance, and ultrasonic sensors use sound waves to detect objects. Applications include object detection, automation systems, security systems, and touchless interfaces.

Inductive Proximity Sensors: Used for metal object detection in industrial automation.

Capacitive Proximity Sensors: Detect the presence of objects based on changes in capacitance.

Ultrasonic Proximity Sensors: Measure distance by emitting and receiving ultrasonic waves.

Applications: Object detection in conveyor systems, automated door control, touchless interfaces in public facilities, security systems for intrusion detection.

What is a motion sensor?

A motion sensor, specifically a Passive Infrared (PIR) sensor, detects the movement of objects or people within its range. It works by detecting changes in infrared radiation emitted by living beings or objects. PIR sensors are commonly used for security systems, occupancy detection, and automatic lighting. Applications include security systems, lighting control, smart home automation, and intruder detection.

Types: PIR sensors are the most common type of motion sensor used in various applications.

Applications: Intrusion detection in security systems, automatic lighting control in buildings, occupancy sensing for energy efficiency, motion-activated cameras for surveillance.

Latest products

-

GEBRABIT WIND SENSORRated 0 out of 5

-

GEBRABIT TSW-20M ModuleRated 0 out of 5

-

GebraBit TDS ModuleRated 0 out of 5

-

GEBRABIT Rain SensorRated 0 out of 5

-

GEBRABIT PH ModuleRated 0 out of 5

-

GEBRABIT Dissolved Oxygen ModuleRated 0 out of 5

-

GEBRABIT Conductivity ModuleRated 0 out of 5

-

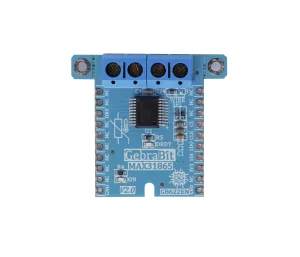

GebraBit MAX31865Rated 0 out of 5