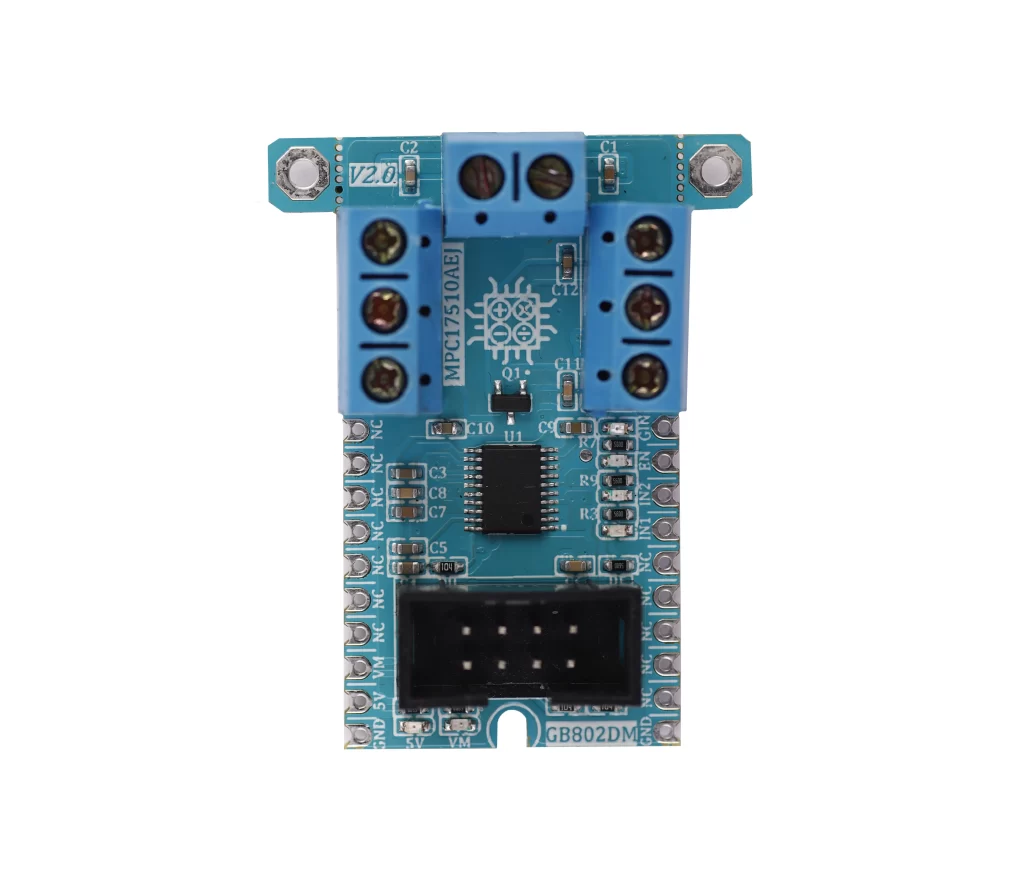

Motor Driver

DC Brushed

We know that good design means good business.

A DC brushed motor is a type of DC motor that uses brushes to make physical contact with the commutator, which is a rotating part of the motor that helps change the direction of current flow within the motor’s magnetic field. The brushes and commutator are used to transfer electrical power from the stationary part of the motor to the rotating part, thereby creating the rotational movement of the motor shaft.

DC brushed motors are commonly used in various applications, including appliances, power tools, and toys, among others. However, they are gradually being replaced by more advanced motor technologies such as brushless DC motors (BLDC) and stepper motors, which offer greater efficiency, reliability, and control.

A brushed DC motor driver is a type of motor driver that is designed to control the speed and direction of a brushed DC motor. A brushed DC motor consists of a rotor (the rotating part of the motor) and a stator (the stationary part of the motor). The rotor has a set of brushes that make contact with the commutator, which is a segmented ring that is connected to the rotor. When current flows through the brushes and commutator, the rotor spins.

A brushed DC motor driver typically consists of a power transistor or MOSFET, a control circuit, and a feedback mechanism. The power transistor or MOSFET is used to switch the current on and off to the motor, while the control circuit adjusts the voltage and current to control the speed and direction of the motor. The feedback mechanism typically consists of a set of sensors that provide information about the motor’s speed and position, which is used to adjust the control signals.

Brushed DC motor drivers are commonly used in a wide range of applications, including robotics, RC vehicles, power tools, and consumer electronics. They are relatively simple and inexpensive to implement, making them a popular choice for hobbyists and DIY projects. However, they are not as efficient as other types of motor drivers and require regular maintenance due to the brushes and commutator.

|

|

Product

|

Type

|

VM

|

Channel

|

Interface

|

DC Output Current

|

Buy

|

DOC

|

|---|---|---|---|---|---|---|---|---|

|

Analog

|

2.5V to 12V

|

Dual channel

|

Digital – Logic, PWM

|

800mA

|

|

||

|

Analog

|

2.0V to 15V

|

Dual channel

|

Digital – Logic, PWM

|

1.2A

|

|

||

|

Analog

|

3.3V to 7.0V

|

Dual Channel

|

Digital – Logic, PWM

|

2A

|

|

Frequently Asked Questions

How many types of brushed DC motor drivers are there?

There are several kinds of brushed DC motor drivers that exist, including:

- Full-bridge driver: Uses four transistors to control the motor, allowing for bidirectional control.

- H-bridge driver: Similar to the full-bridge driver, but with two additional diodes to prevent back-emf from damaging the transistors.

- Half-bridge driver: Uses two transistors to control the motor, allowing for unidirectional control.

- Series driver: Used for low-voltage and high-current applications, with the motor and driver connected in series.

- Shunt driver: Used for high-voltage and low-current applications, with the motor and driver connected in parallel.

- PWM driver: Uses pulse-width modulation to control the motor speed, allowing for more precise control and energy efficiency.

- Linear driver: Uses linear voltage regulation to control the motor speed, but is less efficient than PWM.

The type of driver used will depend on the specific application and requirements of the motor control system.

What is Full-bridge driver?

A full-bridge driver is a type of brushed DC motor driver that utilizes a full H-bridge circuit to control the speed and direction of a motor. The H-bridge consists of four switches that can be turned on and off in various combinations to control the flow of current through the motor. The full-bridge driver is capable of handling high currents and voltages, making it suitable for driving larger DC motors.

The full-bridge driver is a popular choice for robotics and automation applications due to its ability to control the direction of the motor as well as its speed. It is also commonly used in motor control circuits for electric vehicles and other high-power applications.

One common drawback of the full-bridge driver is its complexity, as it requires four switches and additional circuitry to control them. It can also generate a significant amount of heat due to the switching of high currents, requiring additional cooling measures to be taken.

What is H-bridge driver?

An H-bridge driver is a type of DC motor driver that is used to control the direction and speed of a brushed DC motor. It consists of four switches arranged in an H-shaped configuration that can be controlled by a microcontroller or other control circuitry. The switches are typically MOSFETs or transistors that are used to switch the current on and off to the motor, allowing it to rotate in either direction.

The H-bridge driver can be controlled by a variety of signals, such as a pulse-width modulation (PWM) signal, to vary the speed of the motor. By changing the direction of the current flow through the motor, the H-bridge driver can also change the direction of rotation of the motor.

H-bridge drivers are commonly used in robotics, industrial automation, and other applications where precise control of DC motors is required. They are available in a range of sizes and power ratings, and can be used to drive small hobby motors or large industrial motors.

What is DMOS Full Bridge Driver?

DMOS full bridge driver is a type of brushed DC motor driver that uses DMOS transistors to switch the motor current. DMOS stands for Double-Diffused Metal Oxide Semiconductor, which is a type of transistor technology that provides low on-resistance, high current-handling capability, and high-speed switching.

A DMOS full bridge driver is a four-switch configuration that is used to control the direction and speed of the DC motor. It consists of four DMOS transistors that are arranged in an H-bridge configuration. The DMOS full bridge driver can operate at high frequencies and is capable of handling large currents, making it suitable for driving high-power DC motors.

The DMOS full bridge driver operates by controlling the voltage across the motor terminals. By switching the transistors on and off in the appropriate sequence, the motor direction and speed can be controlled. The DMOS full bridge driver also includes protection features such as overcurrent protection and thermal shutdown to protect the motor and the driver circuit from damage.

DMOS full bridge drivers are commonly used in industrial applications such as robotics, automation, and electric vehicles, where high-power DC motors are required to be controlled with precision and efficiency.

What is DMOS Dual full bridge driver?

DMOS dual full bridge driver is a type of brushed DC motor driver that is designed to control two DC motors simultaneously. It consists of two full-bridge driver circuits, each of which can drive a DC motor in both forward and reverse directions. The DMOS dual full bridge driver uses DMOS (double-diffused metal-oxide-semiconductor) technology, which provides high current capacity, low on-resistance, and fast switching speeds.

DMOS dual full bridge drivers are commonly used in various applications, including robotics, automation, automotive, and industrial control systems. They are often used in applications that require precise control over the speed and direction of multiple DC motors, such as robotic arms, CNC machines, and conveyor belts.

One of the advantages of the DMOS dual full bridge driver is its high efficiency. It minimizes power dissipation by using low on-resistance MOSFETs, which reduces heat generation and allows for higher power density. Additionally, many DMOS dual full bridge drivers have built-in protection features, such as over-current protection, over-temperature protection, and short-circuit protection, which increase their reliability and safety.

What is PWM current controller?

PWM (Pulse Width Modulation) current controller is a type of DC motor driver that uses a technique to control the speed and direction of the motor. It works by applying a square wave voltage to the motor, with a varying duty cycle, to control the average voltage and current supplied to the motor.

In PWM current control, the motor is driven with a fixed voltage and a variable duty cycle. The voltage is fixed to the highest voltage the motor can handle, and the duty cycle is varied to adjust the speed and torque of the motor.

The PWM current controller is designed to work with different types of loads, such as DC motors and inductive loads. It is commonly used in industrial automation, robotics, and electric vehicle applications, where precise speed and torque control are required.

The PWM current controller can provide benefits such as improved energy efficiency, reduced motor heating, and increased motor lifespan, compared to other types of motor drivers. It is a popular choice for driving high-power motors in demanding applications.

What are High-density power Motor drivers?

High-density power drivers are electronic components used to drive and control high-power loads such as motors, actuators, and solenoids. These drivers are designed to handle high current and high voltage, making them ideal for industrial applications that require precision control and fast response times.

High-density power drivers are typically used in applications that require high-power output, such as robotics, automation, and power tools. They are available in various configurations, including single-phase and multi-phase configurations, and can be customized to meet specific application requirements.

One of the key benefits of high-density power drivers is their compact size and high power density, which makes them ideal for use in space-constrained applications. They also offer high efficiency and low thermal resistance, which helps to reduce heat generation and extend the life of the driver.

Some common types of high-density power drivers include MOSFET drivers, IGBT drivers, and gate drivers. These drivers are designed to operate with specific types of power devices and have different features and capabilities, such as over-current protection, over-temperature protection, and dead-time control.